REV.-A

PRINCIPLES OF OPERATION

2.3.10 RIBBON-FEED MECHANISM

The ribbon-feed mechanism consists of the ribbon cartridge and the ribbon-feed section. The ribbon-driving

gear always is driven counterclockwise (regardless of the timing-belt direction) via the gear trains shown

in Table 2-10.

Table 2-10. Ribbon-Feed Gear Train

Direction of Movement of Carriage

Left to right

(arrow

*)

Right to left

(arrow

0

)

Gear Train

Beltdriven pulley

-,

Platen gear

(1)

+

Platen gear (2)

+

Ribbon-driving gear

Beltdriven pulley

+

Platen gear (1)

(arrow

d)

-,

Platen gear (3)

+

Platen gear (4)

Ribbon-driving gear

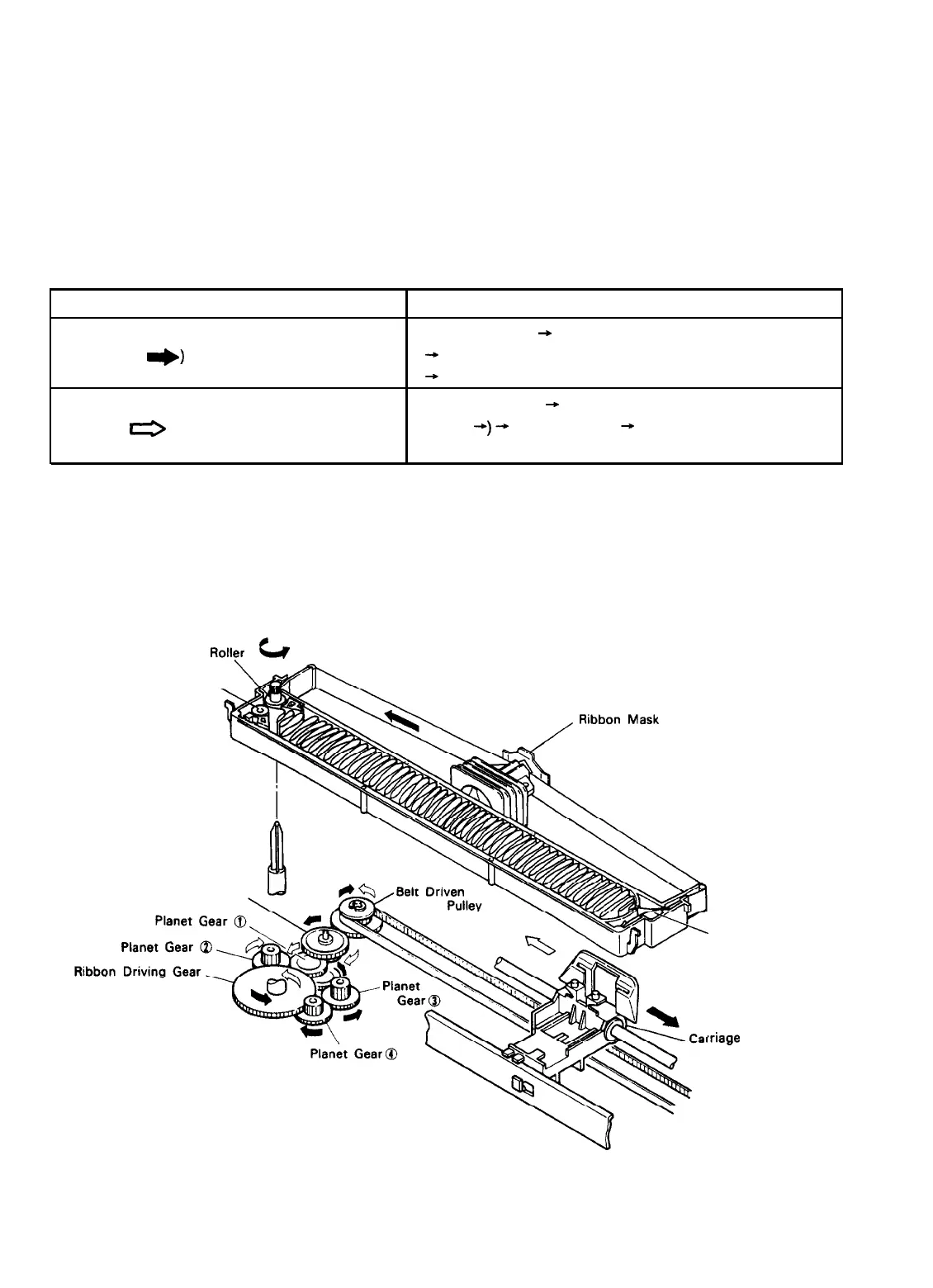

Figure 2-71 shows the ribbon-feed mechanism. The inked ribbon is held in the cartridge case between the

ribbon-feed and the ribbon-pressure roller mounted on the ribbon-driving gear. The ribbon configuration is

such that the ribbon can feed endlessly. The ribbon-driving gear drives the rollers, which causes the ribbon

to be fed. To prevent ribbon slack, a ribbon-braking spring is attached at the exit of the cartridge case. A

ribbon mask is installed to prevent the ribbon from staining the paper.

Ribbon Feed

Roller

Lv

Ribbon Pressure Roller,

Ribbon Transmission Gear

Ribbon

,riage

Braking

Spring

Figure 2-71. Ribbon-Feed Mechanism

LQ-510

2-65

Loading...

Loading...