Epson Stylus Pro 7700/7710/7700M/7710M/7900/7910/9700/9710/9900/9910/WT7900/WT7910/9890/9908/7890/7908 Revision I

TROUBLE SHOOTING Remedies for Print Quality Troubles 163

Confidential

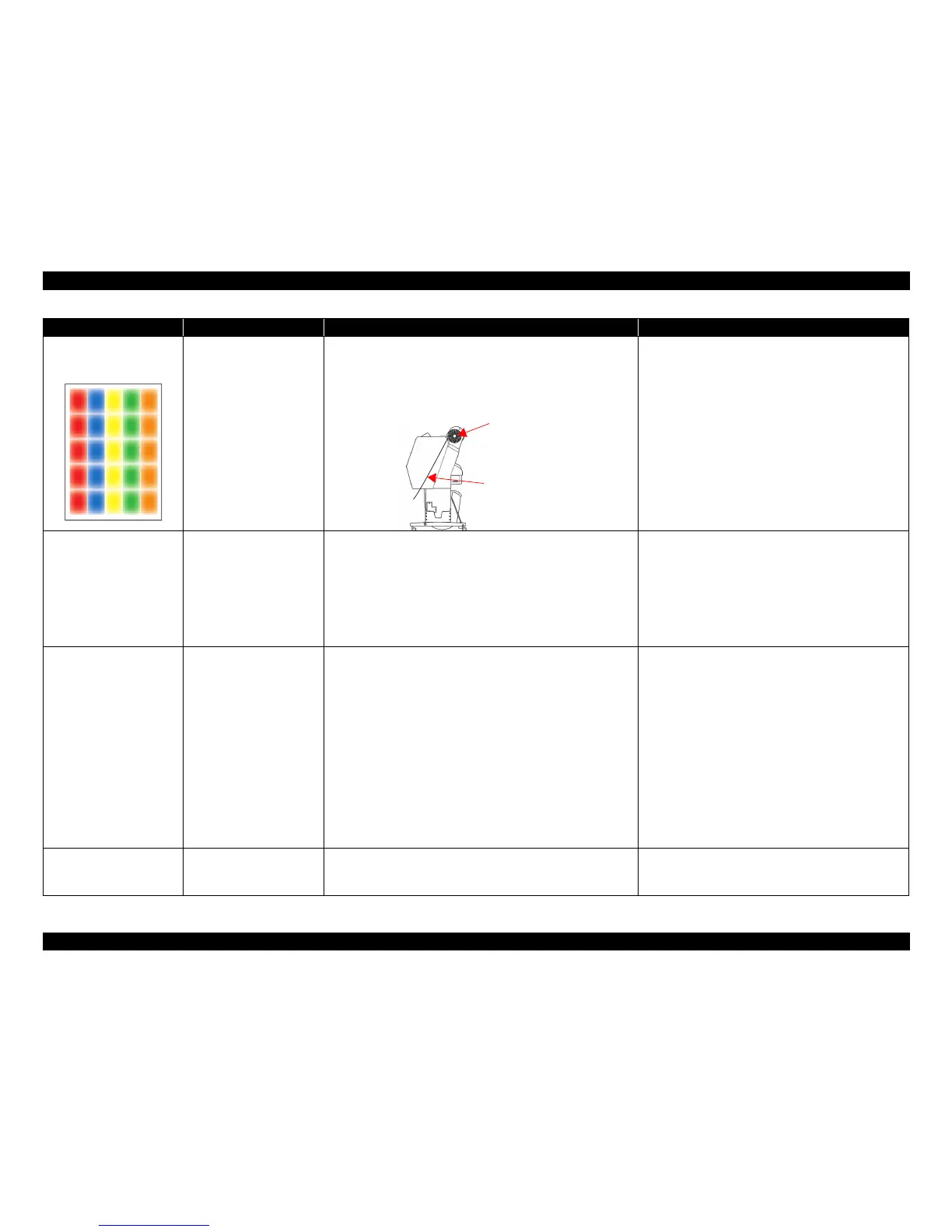

Print is blurred.

Print is thin.

When printing under the

following conditions, print

becomes blurred or thin.

• Media transported in a high

temperature and humidity

environment.

• The CPF was left on the

printer for some time.

If the CPF is left in a high temperature environment and then exposed

to a high humidity environment, spotted ink may not spread enough but

become small dot diameters. In such a case, print may be blurred or

thin. (It occurs conspicuously in yellow.)

• If the CPF is not used for a while, remove the roll from

the printer, wrap it in its individual bag, and then store it

in its individual box.

• Comply with the usage/storage environment.

The printed part in the white

ink becomes transparent.

• When water is attached on

the part printed in the white

ink

• When scotch tape is

attached on the part printed

in the white ink

• When the printed part in

the white ink is laminated

• Due to the characteristics of the white ink. (See above "Uneven

white color" cause.)

• Due to the reaction of the white ink to the lamination type or

method.

• Do not let the printed film get wet.

• Do not attach scotch tape on the printed film.

• Sufficient prior evaluations should be performed in order

to select the most appropriate lamination type and

method.

The white density changes. • The ink cartridge is not

shaken once a week.

• When not printing more

than one month

• When [WHITE INK

REFRESH] is set to OFF

• When the printed part in

the white ink is laminated

• Sedimentation of the white ink in the ink cartridge.

• Sedimentation of the white ink in the nozzle.

• Reaction of the white ink to the lamination type or method.

• Turn the power on once a week, stir the white ink

cartridge and execute the [PRINT WITH WHITE INK] in

[NOZZLE CHECK].

• After the purchase, shake the cartridge box with the

cartridge inside for approximately five seconds before

storing it.

• Store it horizontally.

• When storing the white ink for a long time, shake the

cartridge box with the cartridge inside for approximately

30 seconds (100 times) once in every six months.

• Execute [WHITE INK REFRESH].

• Sufficient prior evaluations should be performed in order

to select the most appropriate lamination type and

method.

Ink sedimentation, oozing In the case of High duty and

Bi-D

Because the drying time is not long enough, the media cannot absorb

ink anymore. (This easily occurs under a low-humidity environment.)

• Lower the white ink duty on the RIP setup or on the

image data.

• Print using Uni-D printing.

Symptom Occurrence condition Cause

Remedy/Points to be checked

Does not occur on the inside of

the roll not exposed to the air.

It occurs on the coated side exposed

to the moisture for a long time.

Loading...

Loading...