Innova 1999

B. AMMETER

WARNING: Make sure the maximum capacity of your charging

system does not exceed the ammeter's dialface capabilities.

NOTE: We strongly recommend professional installation or

assistance when installing an ammeter.

1. Determine routing for ammeter wiring. Use an existing firewall

grommet, or drill a hole through firewall to accommodate wires.

Install a rubber grommet (purchased separately) in hole, use

shrink tubing, or wrap with electrical tape to protect wiring from

chaffing or other damage.

NOTE: Ammeter wiring must be purchased separately. Use 10

AWG wire minimum.

2. Crimp or solder ring terminals (purchased separately) on ammeter

positive (+) and negative (–) wires. Connect wires to ammeter using

two nuts and flat washers. TIGHTEN NUTS SECURELY.

PROPERLY INSULATE ALL CONNECTIONS.

NOTE: This is an "in–line" attachment gauge. NEVER GROUND

GAUGE STUDS OR WIRES.

3. Route wiring through grommet in firewall.

4. Connect ammeter wiring to charging system:

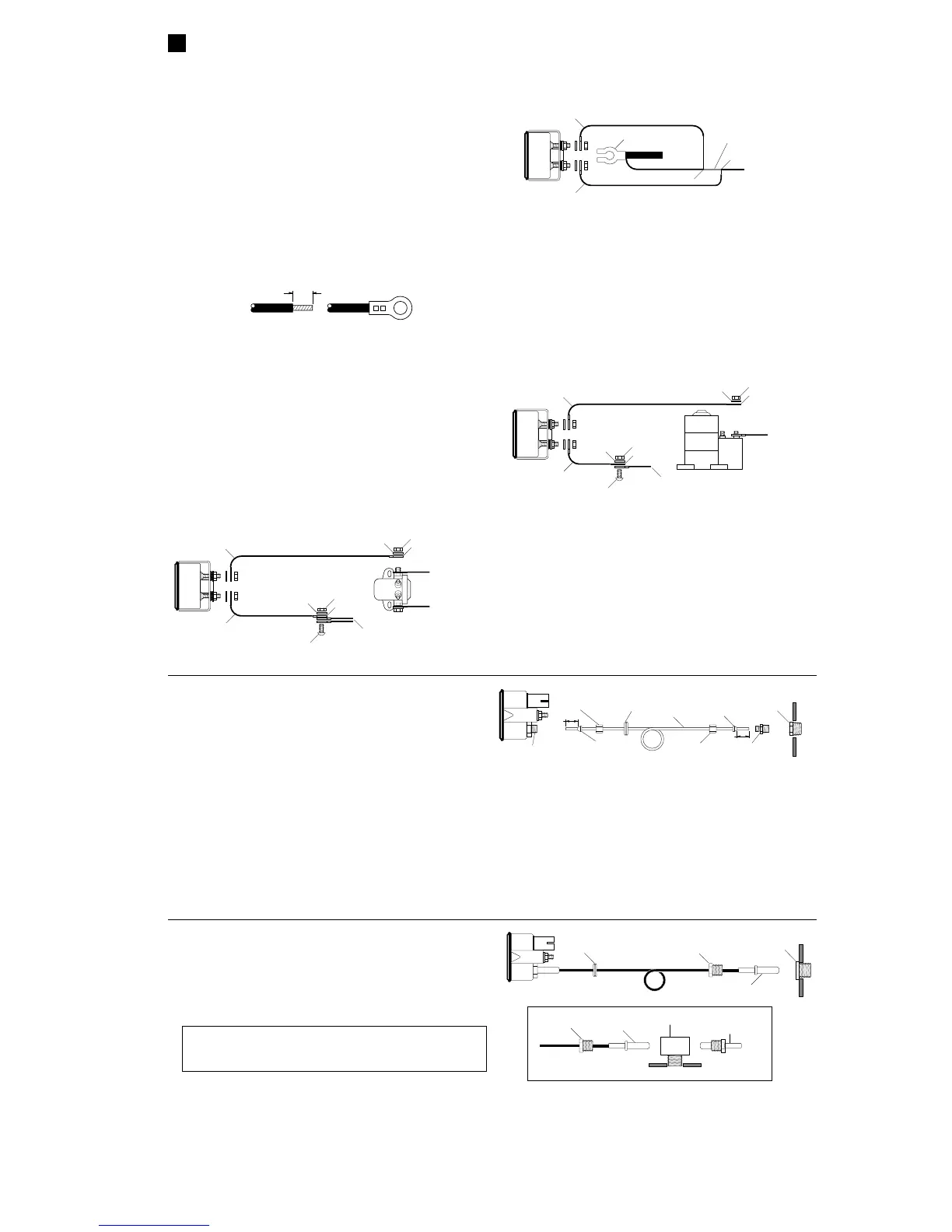

■ For magnetic starter switch systems (Ford/Chrysler), see Wiring

Diagram A. Remove nut and washer from starter solenoid switch

battery connection post "A". Remove all wires except wire going

to battery. Connect ammeter positive (+) lead to post "A";

reinstall washer and nut. Connect ammeter negative (–) wire to

wire(s) removed from post "A" using screw, lockwasher, and nut

(purchased separately).

■ Insulate terminal lug connection using shrink tubing or

electrical tape to prevent shorting.

+

–

BOTTOM

VIEW

NUT

WASHER

TERMINAL

LUG

TO

BATTERY

TO

STARTER

NUT

WASHER

TERMINAL

LUG

SCREW

EXISTING WIRE(S) REMOVED FROM

STARTER SOLENOID SWITCH TERMINAL "A"

AMMETER

NEGATIVE (

–

)

WIRE

AMMETER

POSITIVE (

+

)

WIRE

AMMETER CONNECTION DIAGRAM A (FORD/CHRYSLER)

STARTER

SOLENOID

SWITCH

"A"

+

–

■ For voltage regulator/horn relay circuit systems (GM/Chrysler)

see Wiring Diagram B. Splice ammeter positive (+) and

negative (–) wires into wire from battery positive (+) to voltage

regulator.

■ For most starter solenoid circuits (GM/AMC), see Wiring

Diagram C. Remove nut and washer from starter solenoid

battery connection post "A". Remove all wires except wire

going to battery. Connect ammeter positive (+) wire to post

"A"; reinstall washer and nut. Connect ammeter negative (–)

wire to wires removed from post "A" using screw, lockwasher,

and nut (purchased separately).

■ Insulate terminal lug connection using shrink tubing or

electrical tape to prevent shorting.

5. Reconnect negative (–) battery cable. Turn on headlights and

observe ammeter. Ammeter should indicate "–". If ammeter

reads backwards, reverse the positive (+) and negative (–)

connections. If ammeter fails to read, turn off headlights and

recheck connections.

NOTE: If none of the diagrams matches your vehicle's system,

consult your vehicle's service manual or a qualified mechanic.

+

–

BOTTOM

VIEW

AMMETER

NEGATIVE (

–

)

WIRE

AMMETER

POSITIVE (

+

)

WIRE

AMMETER CONNECTION DIAGRAM B (GM/CHRYSLER)

BATTERY POSITIVE

(+) CABLE

TO

STARTER

SPLICE

SPLICE

CUT AND

REMOVE

TO VOLTAGE

REGULATOR

BATTERY

TERMINAL

+

–

X

+

–

BOTTOM

VIEW

NUT

WASHER

TERMINAL

LUG

TO

BATTERY

NUT

WASHER

TERMINAL

LUG

SCREW

EXISTING WIRES REMOVED FROM

STARTER SOLENOID

AMMETER

NEGATIVE (

–

)

WIRE

AMMETER

POSITIVE (

+

)

WIRE

AMMETER CONNECTION DIAGRAM C (GM/AMC)

STARTER

SOLENOID

+

–

"A"

GAUGE CONNECTION (Continued)

6

1/4"

TRIM INSULATION INSTALL TERMINAL

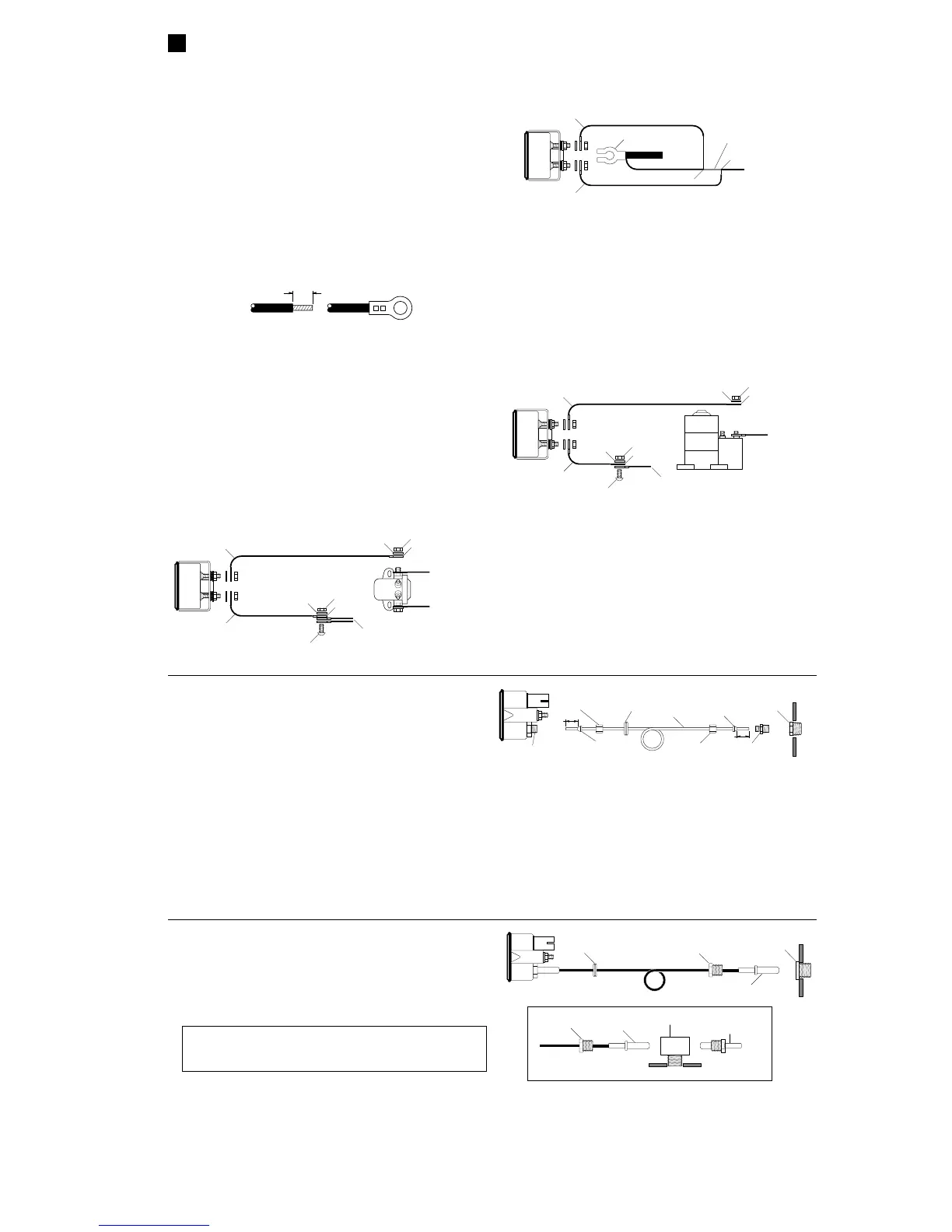

C. MECHANICAL OIL PRESSURE

NOTE: Before installation, use shop cloths and drip pans to protect

vehicle interior from potential leaks.

1. Determine routing for nylon tubing. Use an existing firewall

grommet, or drill a 3/8" (9.5 mm) diameter hole through firewall to

accommodate nylon tubing. Install a rubber grommet (purchased

separately) in hole, use shrink tubing, or wrap with electrical tape to

protect nylon tubing from chaffing or other damage.

NOTE: Some gauges (i.e. #6520) require tubing kit #6801 for

installation.

2. Connect nylon tubing to gauge using compression sleeve and

compression nut. Tighten compression nut until tubing is secure.

3. Route nylon tubing through grommet in firewall.

4. If necessary, install adapter in appropriate pressure port on

engine.

5. Connect nylon tubing to pressure port adapter using tube

connector, compression sleeve and compression nut. Tighten

compression nut until tubing is secure.

6. Secure tubing along its route to prevent damage from sharp

edges, moving parts or hot engine components.

7. Reconnect negative (–) battery cable. Start and run engine for

approximately 30 seconds. Turn off engine and check gauge

installation for leaks. Tighten or reseal joints as needed and

retest.

OPTIONAL

GROMMET

COMPRESSION

SLEEVE

COMPRESSION

NUT

COMPRESSION

NUT

COMPRESSION

SLEEVE

TUBE

CONNECTOR

*

OPTIONAL

ADAPTER*

*

USE TEFLON SEALING TAPE ON NOTED THREAD JOINTS.

NYLON

TUBING

ENGINE

BLOCK

GAUGE

PORT

*

1/8"

1/8"

D. MECHANICAL TEMPERATURE

1. Determine routing for temperature sensor. Use an existing

firewall grommet, or drill a 7/8" (22 mm) hole through firewall to

accommodate capillary tube with sensor. Install a rubber

grommet (purchased separately) in hole, use shrink tubing, or

wrap with electrical tape to protect capillary tube from chaffing or

other damage.

2. Route capillary tube through grommet in firewall.

3. Remove existing temperature sensor. Install adapter in sensor

hole and tighten securely. Insert temperature sensor in adapter

and tighten sensor nut securely. DO NOT ROTATE SENSOR OR

CAPILLARY TUBE WHILE TIGHTENING NUT OR CAPILLARY

TUBE MAY BE DAMAGED.

4. Secure capillary tube along its route to prevent damage from

sharp edges, moving parts or hot engine components. DO NOT

CRIMP THE CAPILLARY TUBE.

5. Reconnect negative (–) battery cable. Start and run engine and

check gauge installation for leaks. Tighten or reseal joints as

needed and retest.

NOTE: An adapter must be used to seat the sensor.

OPTIONAL

GROMMET

SENSOR

NUT

*

TEMPERATURE

SENSOR

ENGINE

BLOCK

OPTIONAL

ADAPTER

*

*

USE TEFLON SEALING TAPE ON NOTED THREAD JOINTS.

GAUGE

TEMPERATURE

SENSOR

ENGINE

BLOCK

OPTIONAL

TEE FITTING

*

EXISTING

TEMPERATURE

SENSOR/SWITCH

ALTERNATE CONNECTION DIAGRAM

SENSOR

NUT

*

NOTE: The capillary tube is under pressure and filled with ether.

NEVER CUT THE TUBE OR ATTEMPT TO REMOVE FROM

GAUGE PORT.

Loading...

Loading...