776-3759 5 06/04/12

FOR BEST PERFORMANCE, PLEASE BE SURE TO DO

THE FOL LOW ING BEFORE USING THIS SPRAY GUN

• Tightentheguntothecupsecurelywiththenutandfittingsupplied.

• Besuretohavetheproperairpressureattheguntooperate.Properairpressureforthistoolshouldnotexceed35PSIforlacquer

and 43 PSI for enamel.

• Adjustfluidcontrolscrewandspraywidthadjustmentscrewtoyourdesiredpatternbeforeusingonproduction.

• Cleanallpartsafteruse.

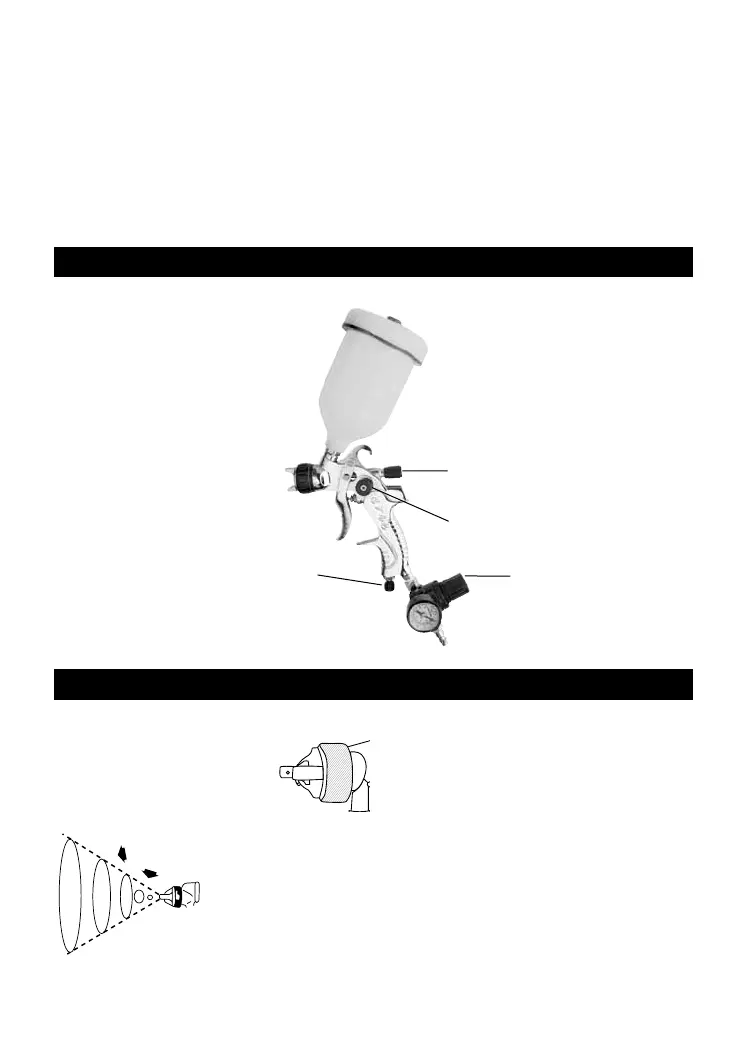

In normal use, the nozzle wings are

horizontal as shown here. This provides a

vertical fan-shaped pattern which gives

maximum,evenmaterialcoverageasthegun

ismovedbackandforthparalleltothesurface

beingfinished.

Spraypatternmaybeinfinitelyadjusted

from round to flat.

Set inlet pressure at no more than 43 PSI. For optimum

performance, some materials may spray better at PSI

ratings below 43 PSI. If unsure, always test at PSI ratings before

usingonfinalproduction.Tryspray.Ifitistoofine,decreasetheair

pressureoropenfluidcontrolscrew.Ifthesprayistoothick,close

the fluid control screw. Regulate the pattern width and repeat

adjustmentofsprayasneeded.

AdjusTmENTs

sprAyiNg

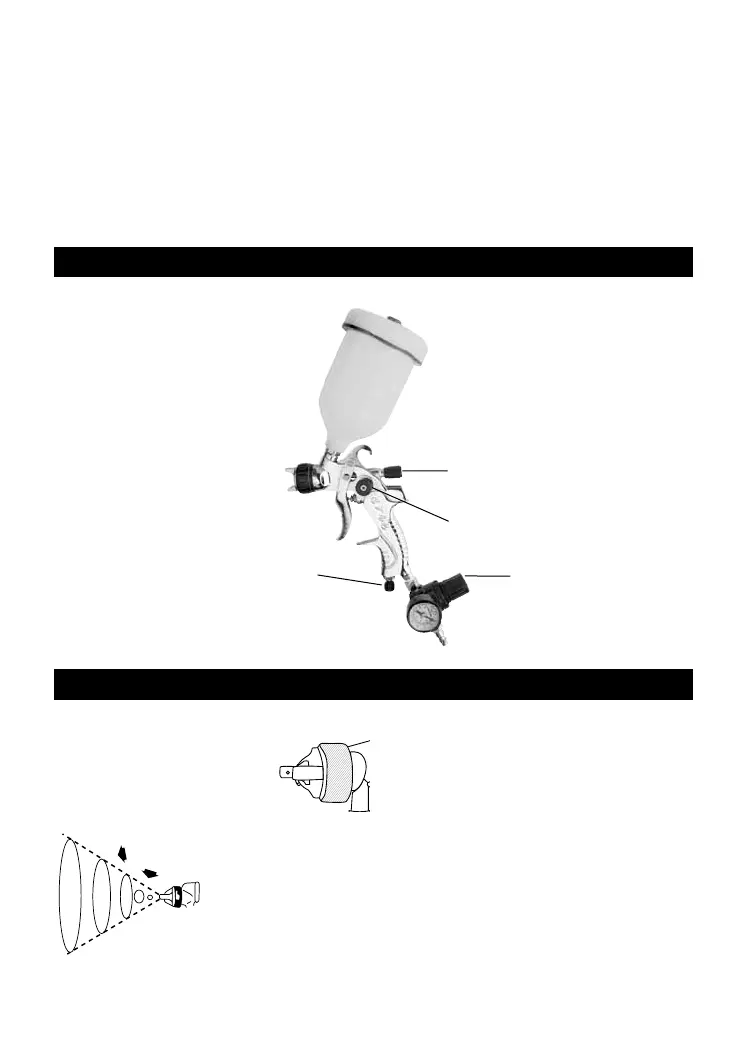

HVLP SPRAY GUN

Themodelyouhavepurchasedisaprofessionalhigh

volume,low pressure spray gun. It is designed to

sprayveryefcientlywithvirtuallynooverspray.To

accomplish this, the inlet pressure regulation is

critical.Pleasebesuretoreadpressurerequirement

carefully.

Fluid control screw

Turnrighttodecreaseflow,

left to increase.

Air pressure regulator

Turnrighttodecreaseairpressure,

left to increase.

Spray width adjustment screw

Turnrightforround,leftforfan.

Air flow adjustment screw

Turnrighttodecreaseflow,

left to increase.

Loading...

Loading...