220

POWERHEAD

POWERHEAD ASSEMBLY

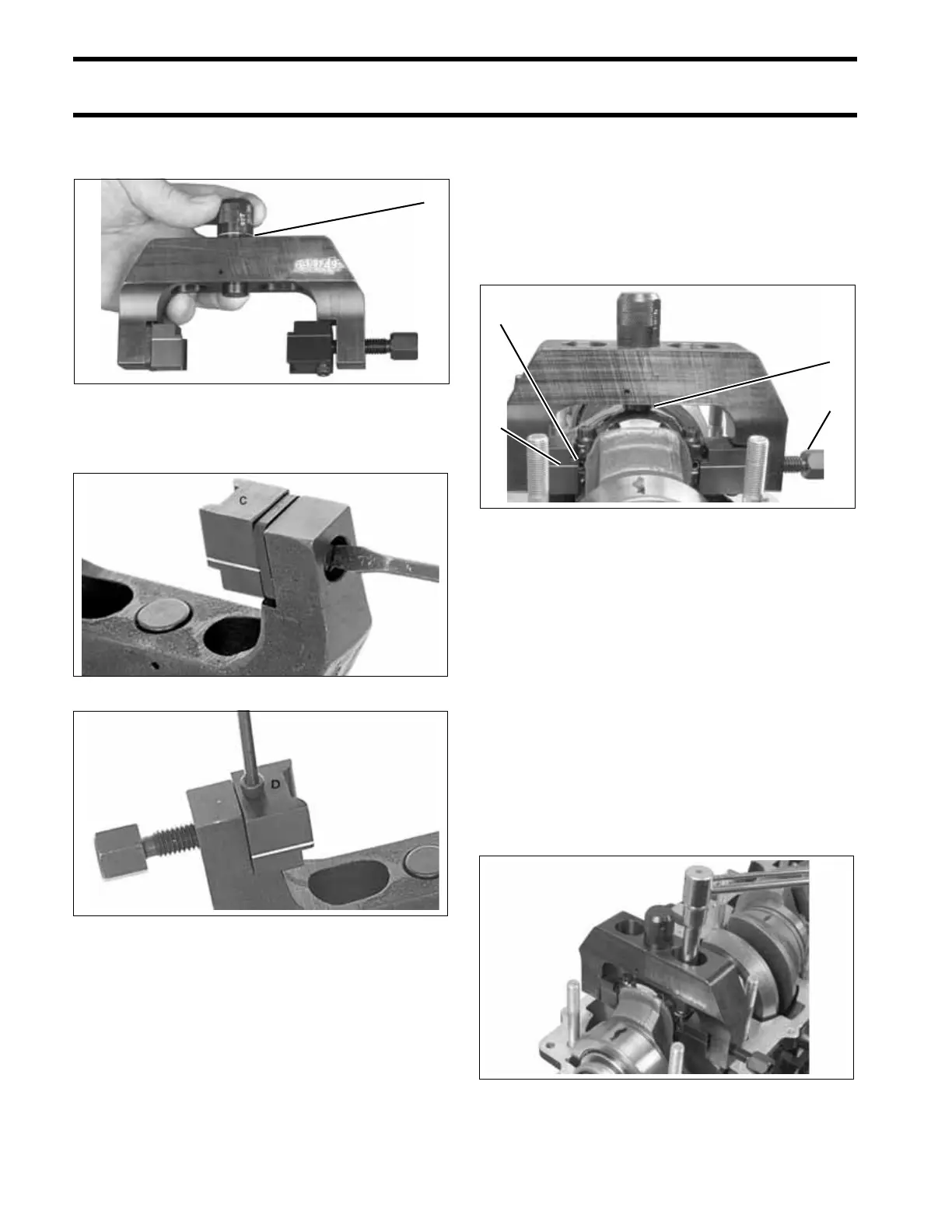

setting (one line showing). Rotate adjustment

knob 180° to lock in position.

.

Secure restraining jaw “C” and forcing jaw “D” to

frame.

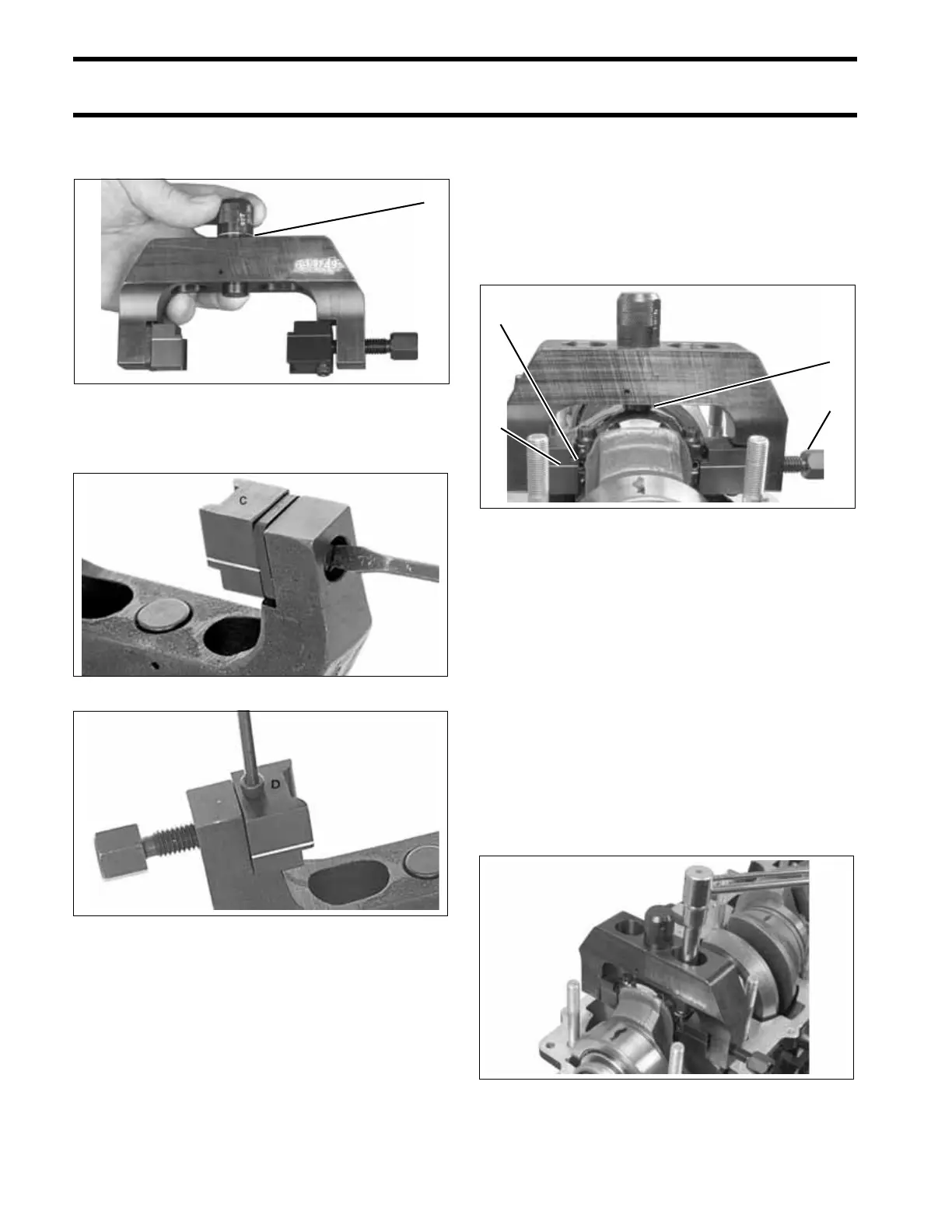

Apply a light coat of outboard lubricant to the cor-

ners of the connecting rod and rod cap. Place

frame on connecting rod using the following pro-

cedure.

• Position frame onto the connecting rod so the

contact area of the jaw is centered on the side

of the rod.

• Tighten forcing screw until jaws contact con-

necting rod.

• Slide frame down until adjustment stop contacts

the rod cap. The groove lines on the jaws must

be centered on the rod/crankpin diameter.

• Tighten the forcing screw to a torque of 14 to 16

in. lbs. (1.6 to 1.8 N·m).

IMPORTANT: Make sure that frame is squarely

in position and that rod and cap are aligned.

Loosen both rod cap screws one-quarter turn.

Use Torquing Socket, P/N 331638, to tighten rod

cap screws in three stages:

• Apply first torque of 40 to 60 in. lbs. (5 to 7 N·m)

to both rod cap screws.

• Tighten screws to a torque of 14 to 16 ft. lbs.

(19 to 21.7 N·m).

• Apply final torque of 30 to 32 ft. lbs. (41 to 43

N·m).

1. Center position, one line showing 002484

Restraining Jaw “C” 21591

Forcing Jaw “D” 21594

1

1. Contact area of jaw

2. Forcing screw

3. Adjustment stop

4. Groove line

002071

002072

3

2

1

4

Loading...

Loading...