Exergen Temporal Artery Thermometry

Calibration Verification Procedure

Suitable for All TAT-5000 and TAT-5000S Models

All Exergen infrared thermometers are

designed to permanently maintain their

accuracy, and feature a patented

hermetically-sealed optical system which

protects the internal optical system against

contamination by dirt, dust, moisture, and

solvents.

Most reported problems are the result of a

dirty lens. As infrared thermometers take an

optical measurement, a dirty lens can result

in a low reading. Cleaning the lens will

result in an immediate return to normal

calibration.

Normally, recalibration is never required

unless the thermometer has been physically

damaged or experiences component failure.

Recalibration is done only at the factory, but calibration verification can be conveniently accomplished

with a Calibration Verification Kit in biomedical engineering, and other areas requiring frequent

accuracy verification of patient thermometry such as blood donor or pheresis units.

Calibration Verification Kit (CVK)

The CVK includes a portable blackbody heat generator providing a stable source of heat in a small

cavity. This is used as a target reference to

verify the calibration of any of Exergen’s

medical instruments against an Exergen

Certified Master (CM) reference instrument,

also included in the kit. The CM instrument

must be of the same type calibration as the units

to be tested (S/N label letters A or O need to

match). If this is not the case, please contact

Exergen.

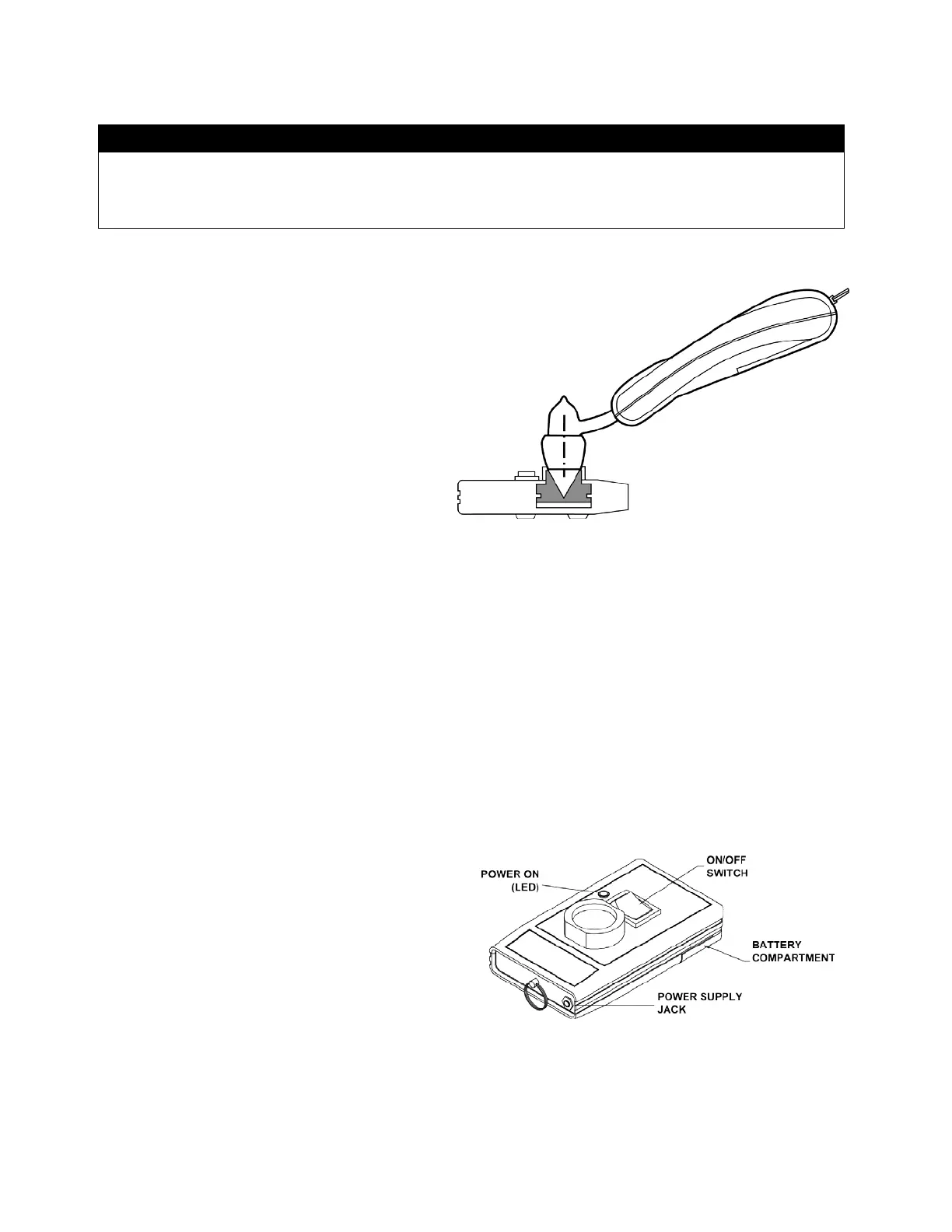

The verifier operates with either a 9-volt power

supply plugged directly into a 90 to 264 VAC

electrical outlet allowing its extended use, or for

portable use on nursing floors, it can be

completely powered by a 9-volt battery.

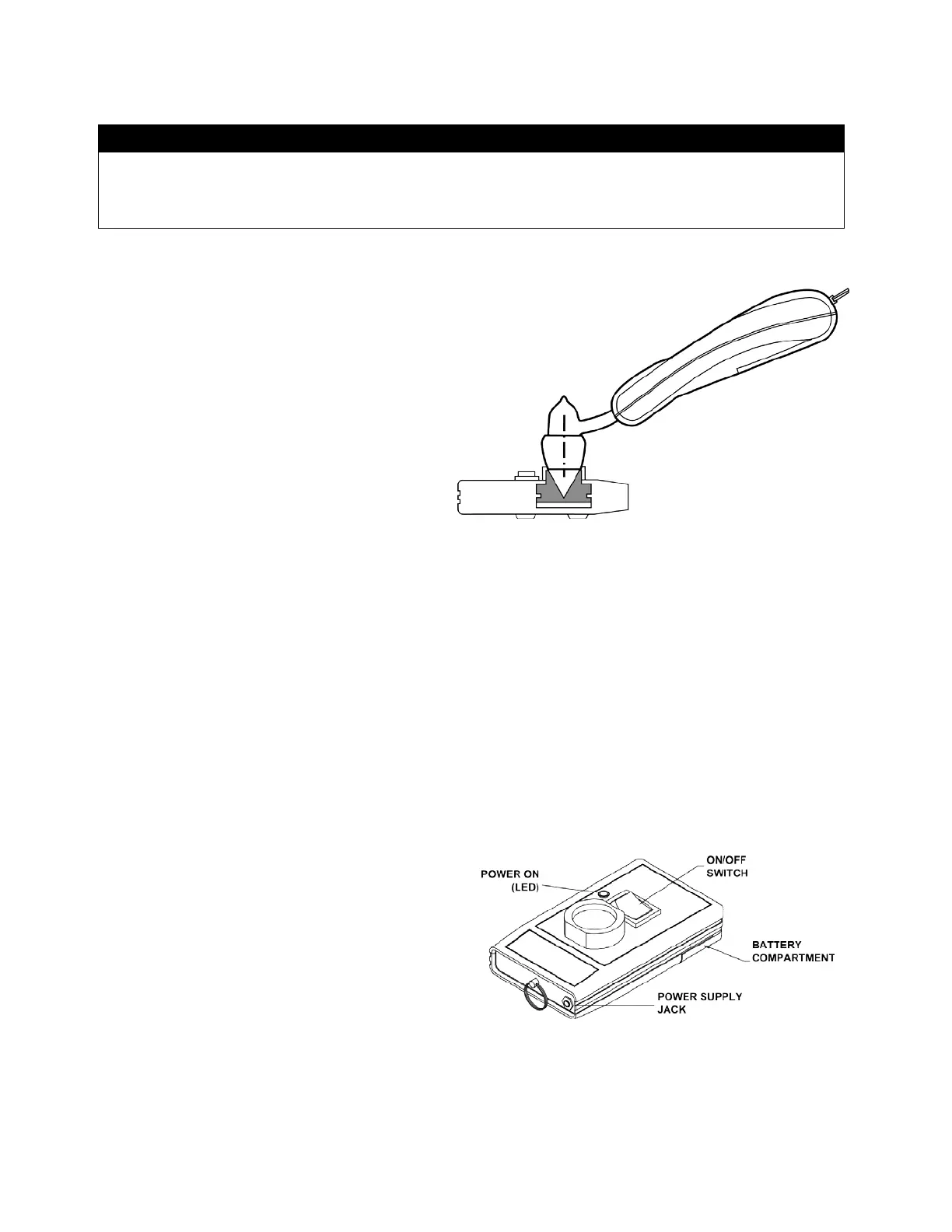

Figure 1. Portable black body is used to verify the

calibration of any TAT-5000 or TAT-5000S vs. a Certified

Master, by comparison of readings.

Figure 2. Model PBB-1 Portable Blackbody

Calibration Verifier

Loading...

Loading...