- 31 -

5.1.19 Wheel hub - slotted nut torque specification.

When tightening the slotted nut on the wheel motor tapered shaft:

a) Torque the slotted nut to 100 ft. lbs.

b) Further tighten the nut until the next set of slots line up with the cross hole

in the shaft.

c) Replace cotter pin.

5.1.20 Thread locking adhesives such as “Loctite 242” or “Fel-Pro, Pro-Lock Nut-

Type” are used on the following fasteners:

a) Pump drive sheave setscrews.

b) Square head setscrews on Hydro pump control arms.

c) OPC lever setscrews.

d) Sheave retaining bolt in end of engine crankshaft.

e) Lower Sheave retaining bolt on clutch arm.

f) Shoulder bolts in ends of speed control crank.

Adhesives such as “Loctite RC/609 or RC/680” or “Fel-Pro Pro-Lock Retaining

I or Retaining II” are used on the following:

a) OPC lever hubs and cross-shaft

NOTE: Care must be used

not

to bond the bearing, next to each OPC

hub, to the cross shaft which could cause binding of the OPC levers and

erratic operation.

5.1.21 An anti-seize compound is used on the following locations:

a) Between engine crankshaft and pump and blade drive sheaves.

b) On clutch arm assembly between bearings and shaft and between lower

sheave and shaft.

c) Between pump shafts and sheaves.

d) Between the cutter housing spindles and the sheaves.

e) Between the cutter housing spindles and the bearings.

5.1.22 Dielectric grease is used on all blade type electrical connections to prevent

corrosion and loss of contact.

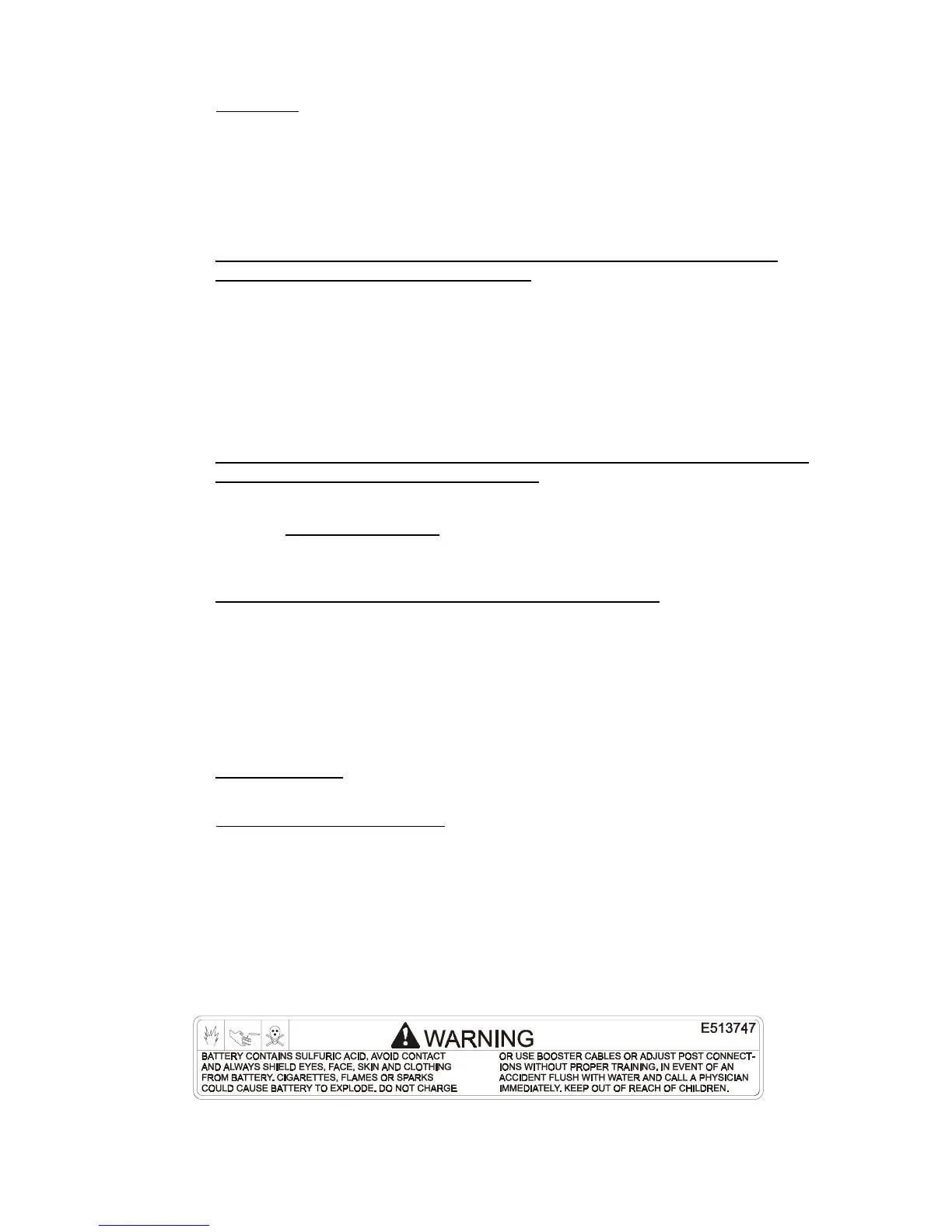

5.1.23 Check battery electrolyte level: (Electric start units only)

Service Interval: 40 hrs.

a) Stop engine and wait for all moving parts to stop. Remove ignition key or

spark plug wire(s).

b) Tilt seat up.

c) Remove vent caps from battery. Fill with water (distilled is recommended)

to bottom of vent wells and replace vent caps.

d) See Assembly Section 3.17, for servicing a new battery.

PART NO. 513747 LOCATION: Battery cover

Loading...

Loading...