B-83144EN/01 SAFETY PRECAUTIONS

s - 7

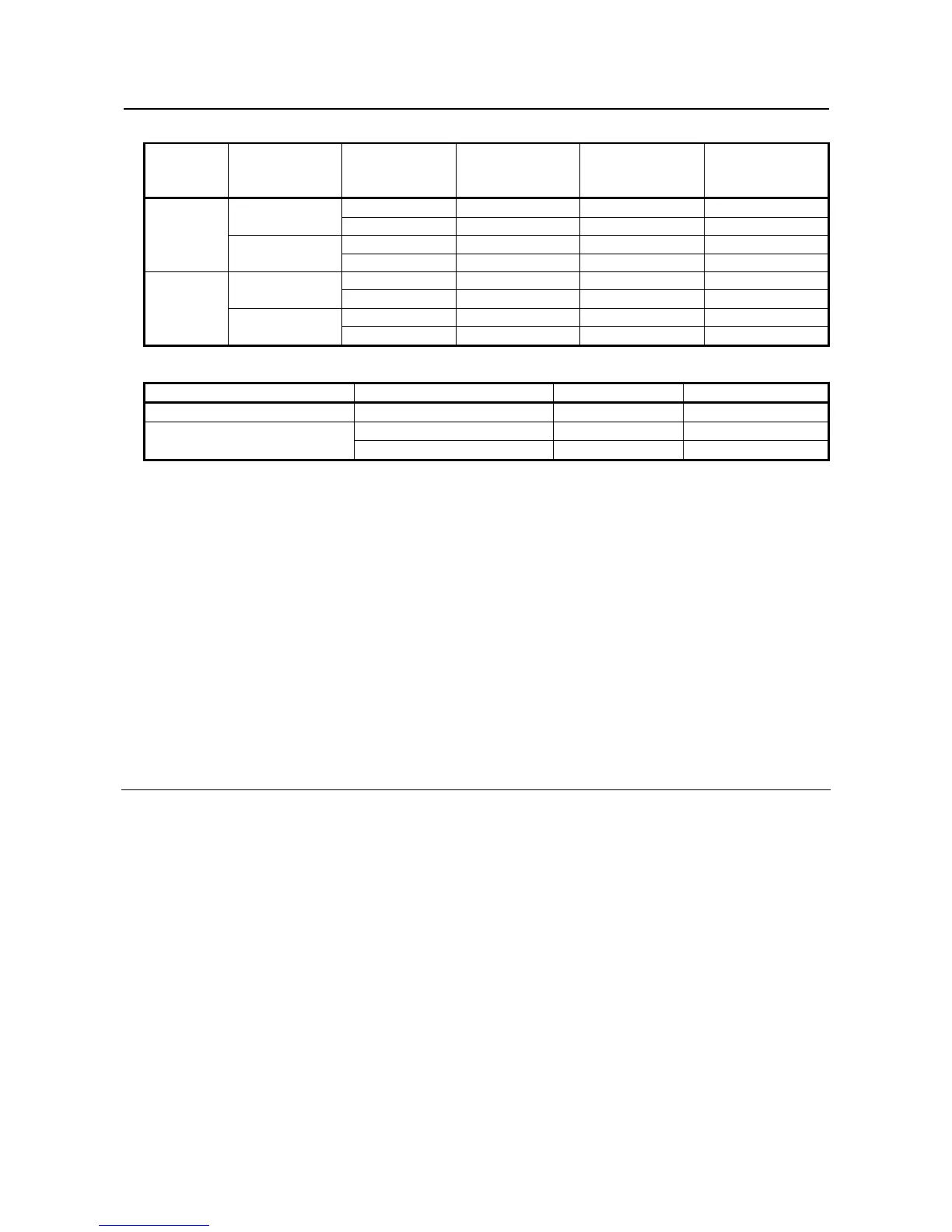

In case of R-30iA Controller or CE or RIA specification of R-30iA Mate Controller

Mode

Teach pendant

enable switch

Software

remote

condition

Teach pendant Operator panel Peripheral device

Local Not allowed Not allowed Not allowed

On

Remote Not allowed Not allowed Not allowed

Local Not allowed Allowed to start Not allowed

AUTO

mode

Off

Remote Not allowed Not allowed Allowed to start

Local Allowed to start Not allowed Not allowed

On

Remote Allowed to start Not allowed Not allowed

Local Not allowed Not allowed Not allowed

T1, T2

mode

Off

Remote Not allowed Not allowed Not allowed

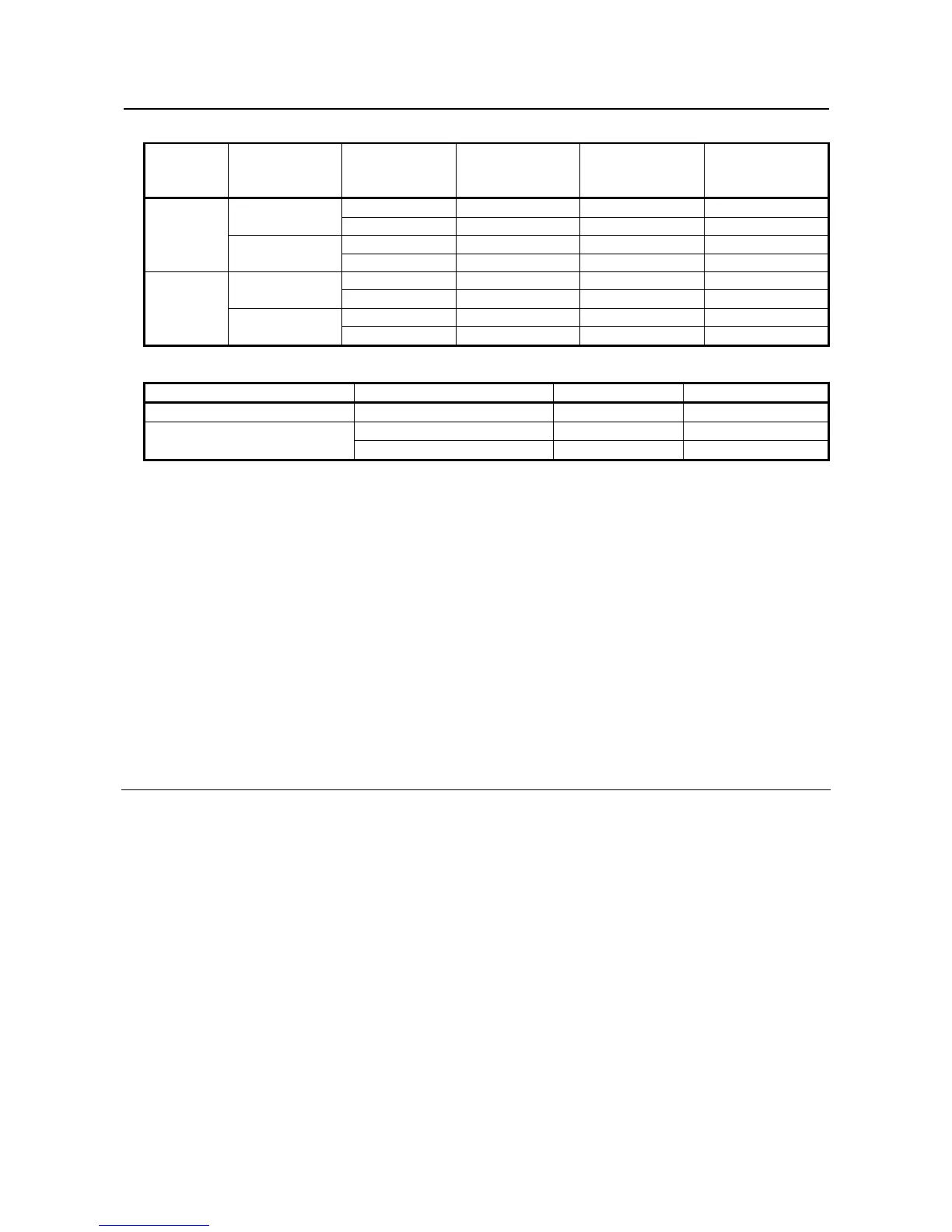

In case of standard specification of R-30iA Mate Controller

Teach pendant enable switch Software remote condition Teach pendant Peripheral device

On Ignored Allowed to start Not allowed

Local Not allowed Not allowed Off

Remote Not allowed Allowed to start

(5) (Only when R-30iA Controller or CE or RIA specification of R-30iA Mate controller is selected.) To

start the system using the operator’s panel, make certain that nobody is the robot work area and that

there are no abnormal conditions in the robot work area.

(6) When a program is completed, be sure to carry out a test run according to the procedure below.

(a) Run the program for at least one operation cycle in the single step mode at low speed.

(b) Run the program for at least one operation cycle in the continuous operation mode at low speed.

(c) Run the program for one operation cycle in the continuous operation mode at the intermediate

speed and check that no abnormalities occur due to a delay in timing.

(d) Run the program for one operation cycle in the continuous operation mode at the normal

operating speed and check that the system operates automatically without trouble.

(e) After checking the completeness of the program through the test run above, execute it in the

automatic operation mode.

(7) While operating the system in the automatic operation mode, the teach pendant operator should leave

the robot work area.

1.2.3 Safety of the Maintenance Engineer

For the safety of maintenance engineer personnel, pay utmost attention to the following.

(1) During operation, never enter the robot work area.

(2) Except when specifically necessary, turn off the power of the controller while carrying out

maintenance. Lock the power switch, if necessary, so that no other person can turn it on.

(3) If it becomes necessary to enter the robot operation range while the power is on, press the emergency

stop button on the operator panel, or the teach pendant before entering the range. The maintenance

personnel must indicate that maintenance work is in progress and be careful not to allow other people

to operate the robot carelessly.

(4) When disconnecting the pneumatic system, be sure to reduce the supply pressure.

(5) Before the start of teaching, check that the robot and its peripheral devices are all in the normal

operating condition.

(6) Do not operate the robot in the automatic mode while anybody is in the robot work area.

(7) When you maintain the robot alongside a wall or instrument, or when multiple workers are working

nearby, make certain that their escape path is not obstructed.

(8) When a tool is mounted on the robot, or when any moving device other than the robot is installed, such

as belt conveyor, pay careful attention to its motion.

Loading...

Loading...