FNM® Series HPE – Installation Manual – 31

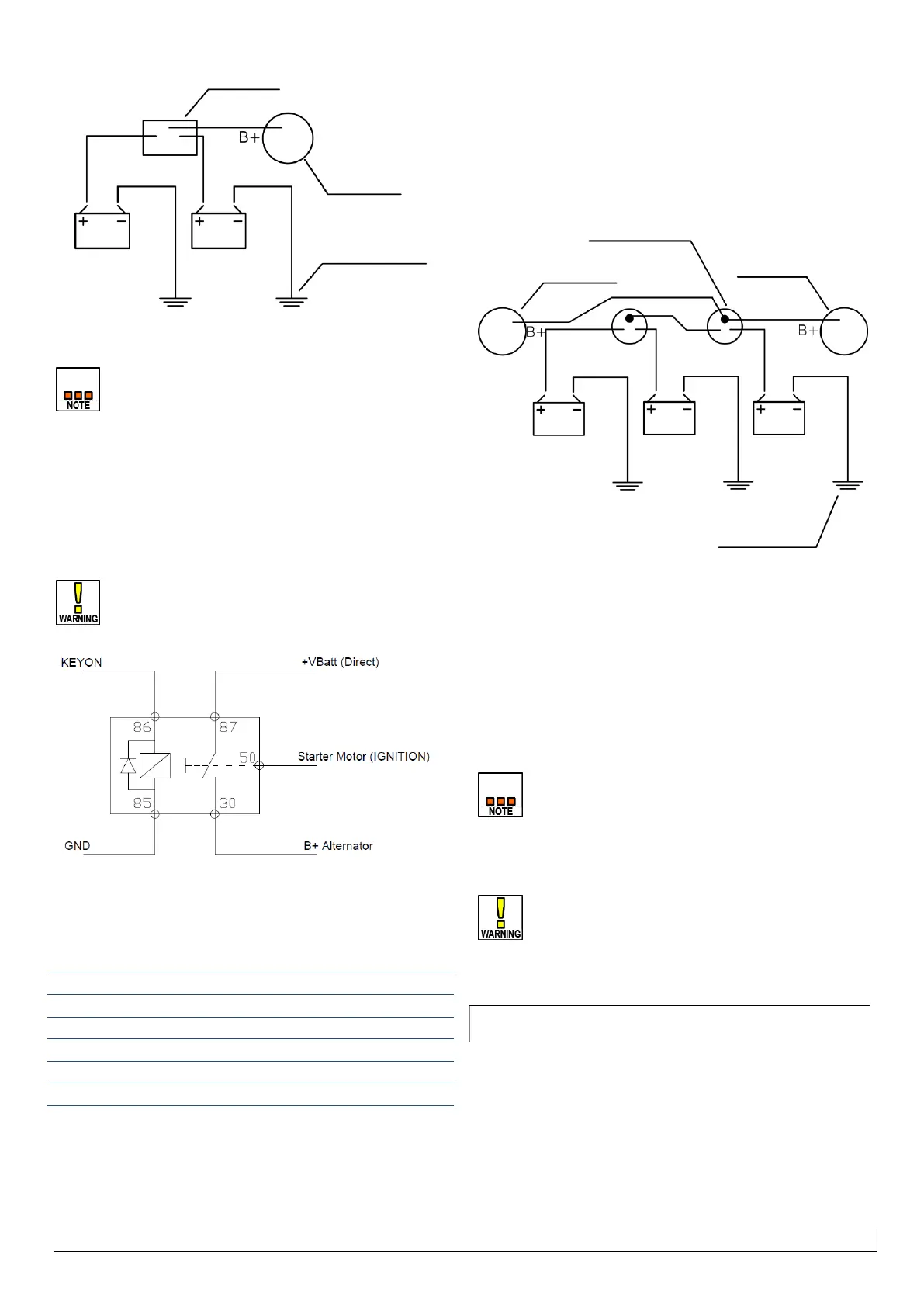

Figure 34 - Wiring diagram for single-engine, double battery

installation.

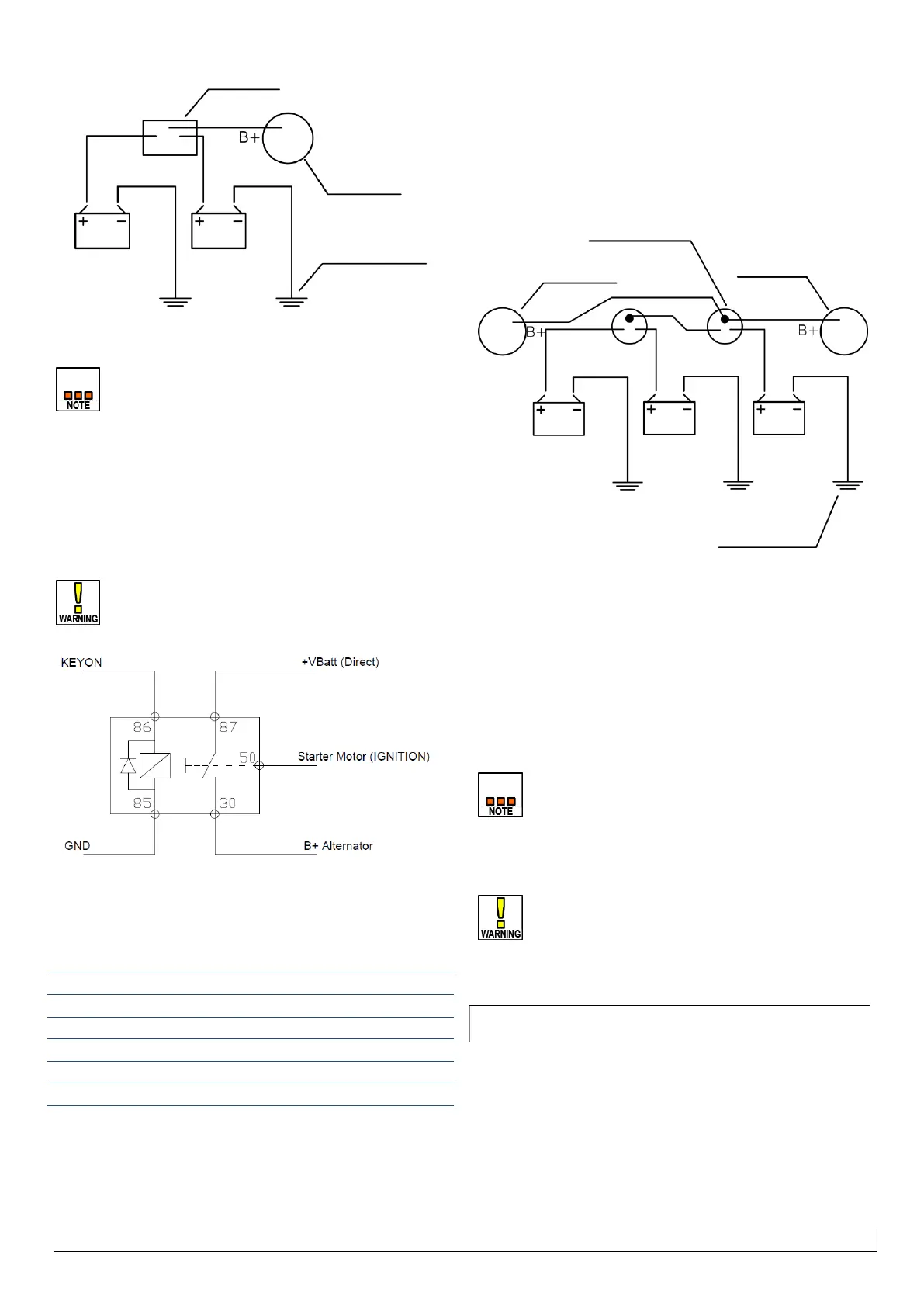

Some load dispatchers do not allow the energizing of

the alternator to charge the battery.

In the presence of load dispatcher, depending on the

model and type of dispatcher, it can happen that the

alternator is not energized and the battery is not

recharged. In this case it is necessary to use a timed relay

connected as in Figure 35 sotto to temporarily energize

the alternator and allow the batteries charging.

Use only relays that match the codes: Writtin

Electronic® 600 100; Wehrle® 51 233 016; Imel:

I18086.

Figure 35- Wiring diagram of timed relay connection for load

dispatcher

Connect the pins using the minimum cross sections

shown in the table:

3. Twin installation, two batteries: connect the batteries to

the two engines as in case 1, keeping the two circuits

separate.

4. Twin installation, three batteries: recommended

connection in case of twin installations and the need for

redundancy for selective charging of multiple batteries.

Follow the wiring diagram below. Two battery exchangers

provide the possibility of using and charging the various

batteries individually or in parallel connection by means of

manual selection.

Figure 36 - Wiring diagram of three batteries in twin installation.

6.2.3 Ground circuit

Make sure that the frames of all metallic elements (including

transom, inverters, etc ...) in the engine compartment are

electrically connected to each other and to ground with cable

of suitable diameter (see table in paragraph 6.2.1 – Cables

diameter and length – on page 29).

The galvanic currents generated between different

metals can, in some instances, lead to premature

corrosion of the metal elements in contact with the

sea water.

For engine installations on metal hulls, it is

necessary to study an appropriate electrical

insulation system between the engine and

transmission, and use a insulated pole engine

control system (see chapter 8.4 – Insulated Pole Kit

on page 45).

6.3 Control Unit

The engine control unit (hereafter ECU - Electronic Control

Unit) is a complex electronic assembly that manages the

operation of the engine in all its aspects.

The ECU is enclosed in a metal box with IP67 protection

against external agents.

Ground point on

the crankcase

Ground point on the crankcase

Loading...

Loading...