FNM® Series HPE – Installation Manual – 43

8 Accessories

8.1 Heating Kit (Boiler)

The kit boiler allows the extraction of a part of the cooling

liquid to feed, with the heat produced by the engine, an

external thermal device.

The kit varies depending on the engine model. Even the

sampling points and the re-entry of the cooling liquid extracted

depend on the model of the engine.

HPE 40S/80/80SD/ 110/110JD

HPE 40/150/150JD/170/

170JD/190/190JD

The diameter of the heating pipes is 16 mm (5/8 in). All

elements of the heating circuit must withstand temperatures up

to 130°C and pressures up to 3 bar.

Follow the diagrams shown. Do not change the

fittings size or location as this will damage the

engine.

Make sure that the heating fitting is with closed

circuit and there is no leakage of coolant. Check the

correct operation of the system.

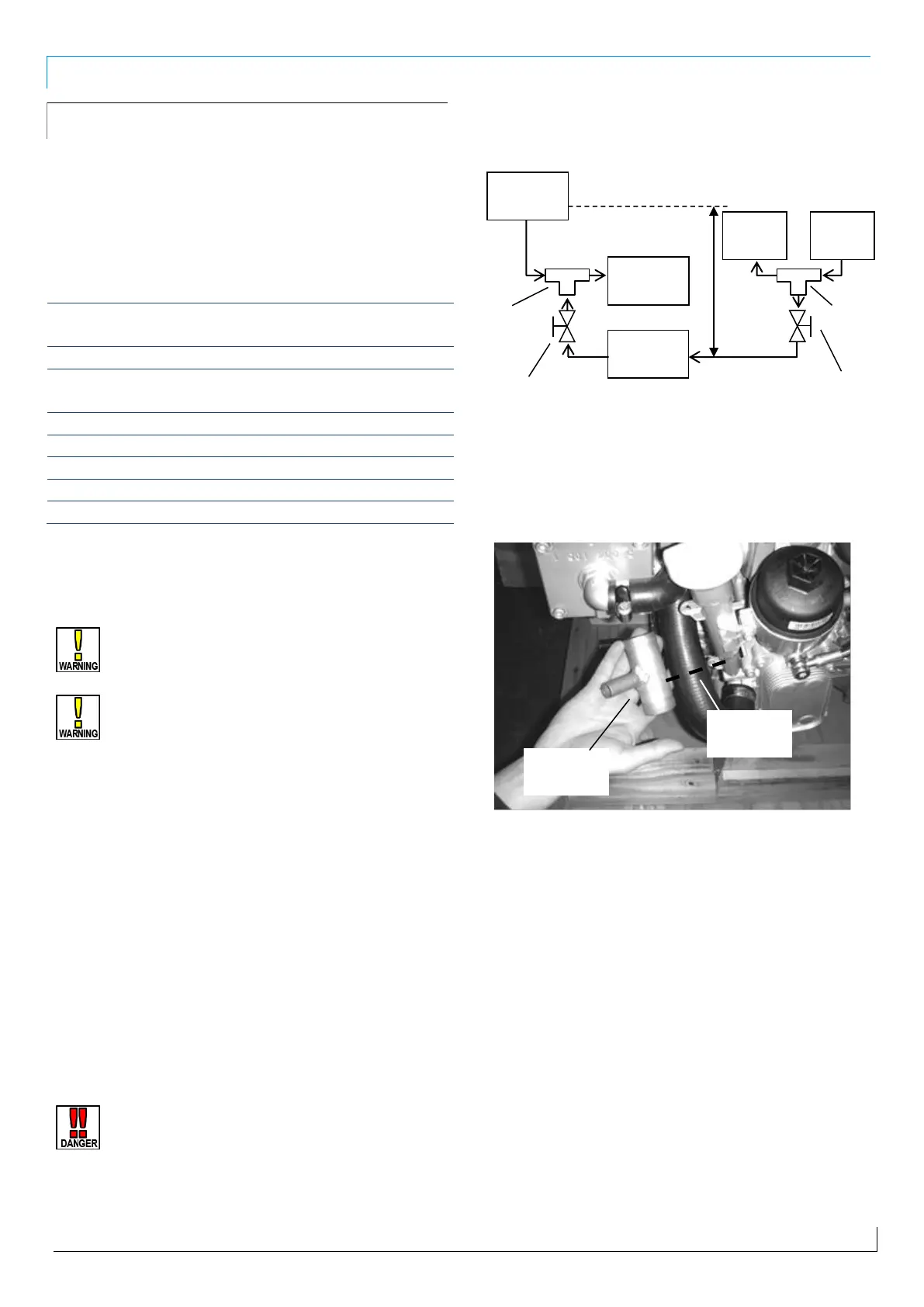

In the heating kit installation it is always required to add two

valves in correspondence of the sampling points (flow) and

return (re-entry) in the circuit for isolating, where necessary,

the heater and facilitate maintenance operations.

When connecting the heating kit it is necessary to restore the

coolant level in the tank to compensate the volume of liquid

which is absorbed by the heater circuit.

It is also necessary to bleed the circuit to ensure the absence

of air.

After installation, check the correct operation of the kit and that

the engine performance is maintained. Check the coolant level

in the tank and check for leaks.

The engine operation with low coolant level

quickly leads to overheating, causing damage to

the seals and internal parts of the engine.

Follow the instructions in the following paragraphs for the

correct installation of the heating kit.

8.1.1 Engine family 1.3 HPE

To connect the kit follow the diagram below:

Figure 53 - Wiring diagram for heating kit on 1.3 HPE base engine

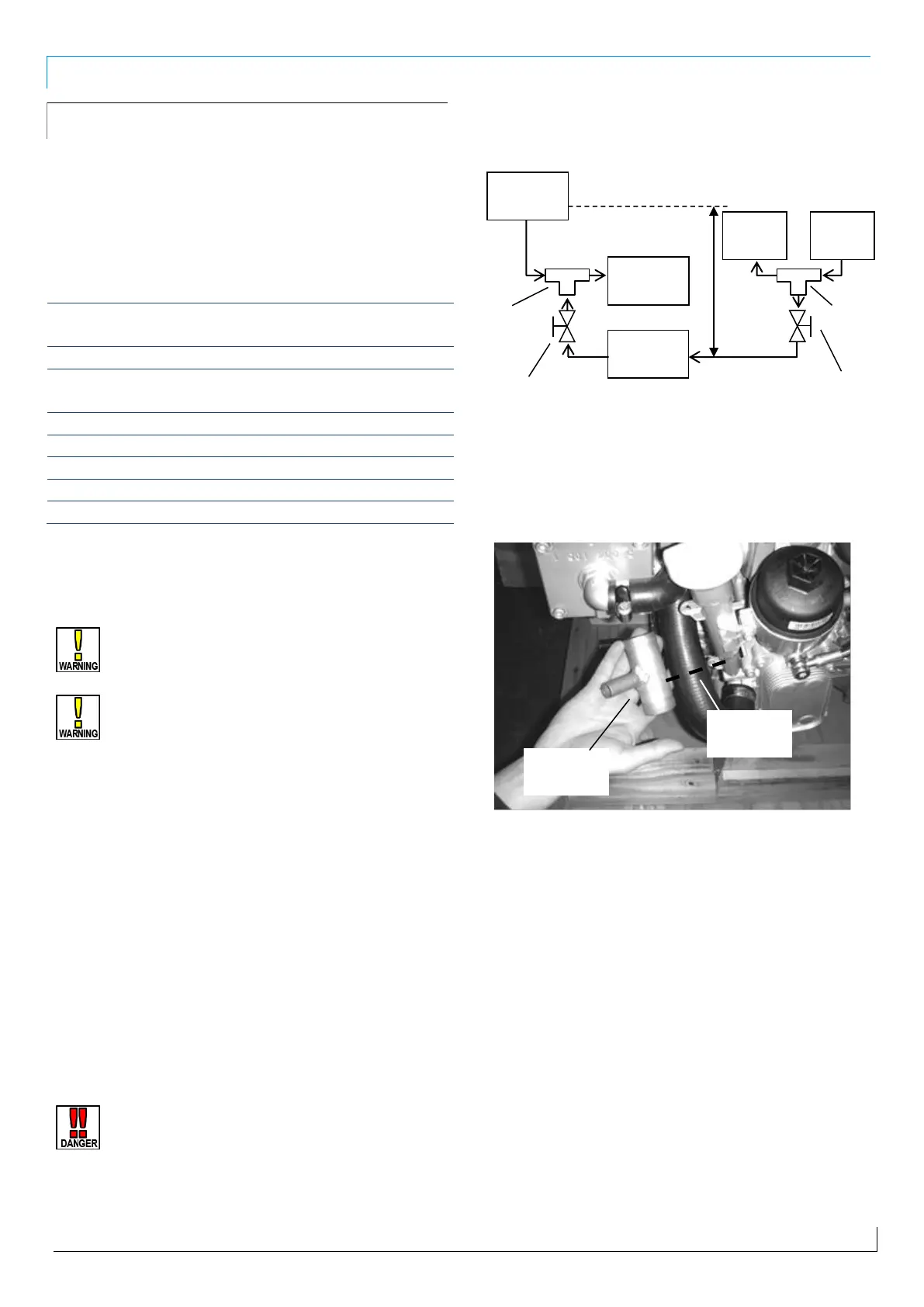

Insert the three-way delivery fitting cutting the sleeve between

the thermostat and oil cooler in the point shown in the

following image:

Figure 54- Sleeve to be cut to connect the boiler kit delivery

connection on 1.3 HPE base engines.

Connect the two halves of the cut sleeve at the ends of the 32

mm (1 ¼ in) diameter fitting , and then connect the input of the

heater circuit at the 16 mm (5/8 in) diameter end.

Insert the three-way return fitting cutting in half the sleeve

between the expansion tank and the coolant pump as in the

following figure:

Return valve

(not provided)

Delivery valve

(not provided)

Loading...

Loading...