PART

2-1 -

General Brake Service

2-3

pair

or

adjustment

due to

inability

of

the parking brake

to

hold against

moderate vehicle movement. Perform

tests

of the

parking brake system

and

controls after making certain

the

link-

age

and

manual controls operate

properly.

Diagnosis

of

vacuum release

sys-

tems

is

basically similar

to

electrical

diagnosis. That

is, the

vacuum

sys-

tem must

be

complete from

the

source

to the

vacuum components.

Any leaks, like

a bad

connection will

make

the

system inoperative.

If a

leak

develops

in one of the

vacuum

sys-

tems,

one or all of the

vacuum

com-

ponents

may

become inoperative. This

would

be

dependent

on the

location

of

the vacuum leak.

If the

leak

is in the

vacuum supply,

all

systems will

be-

come inoperative.

If the

leaks

is in

the component side

of the

vacuum

control

for the

specific system,

all

other systems will operate when

the

leaking system

is off.

When testing

a

parking brake

vacuum release system,

a

minimum

of

10 inches

of

vacuum

(Hg.)

should

be

available

at all

points where vacuum

is applied. This

can be

checked with

a Rotunda Fuel Pump Tester

Gauge (ARE345)

and two

Distributor

Tester hose adapters (Marked

Q)

connected together with

a

coupling.

This allows

the

Fuel Pump Tester

Gauge hose

to be

adapted

to any

other vacuum hose

or

rubber connec-

tor

in

the vacuum systems.

Failure

to

maintain

10

inches

of

vacuum

(Hg)

during vacuum system

tests could

be

caused

by a

loose hose

connection, resulting

in a

vacuum

leak. When checking

for

vacuum

be-

tween

two

points, trace

the

hose along

the entire routing

to be

sure

it is not

crossed with another hose

and con-

nected

to the

wrong connection.

All

of the

vacuum parking brake

control checks

are to be

performed

with the engine running

at

idle speed.

Leaks

in the

parking brake hoses

or

a

disconnected

or

improperly

con-

nected hose

can

usually

be

found

by

listening

for a

hissing sound along

the hose routings. Under

no

circum-

stances should

air

pressure

be

applied

to

the

vacuum system

as the

actuator

diaphragm

in the

parking brake

vac-

uum motor may be damaged.

1.

Start

the

engine

and run it at

idle speed. With

the

transmission

shift control

in

neutral, depress

the

parking brake pedal

to

apply

the

parking brake. Move

the

transmission

shift control

to D

range

and ob-

serve

the

parking brake pedal

to see

that

the

pedal moves upward

and the

parking brake releases.

If the

parking

brake releases,

the

parking brake

vacuum control

is

working properly.

2.

If the

parking brake does

not

release, test

for

vacuum

at the

steering

column neutral switch port

in the

junction block, vacuum lines

and the

parking brake release vacuum motor.

Use

the

Rotunda Vacuum

and

Fuel

Pump Tester

345.

This

can be

accomplished

by

removing

the

hose

from each component

and

attaching

it

to the

vacuum gauge. Connect

two

distributor tester vacuum hose adapters

together with

a

coupling

as a con-

nector

to

attach

the

gauge.

A

mini-

mum

of ten

inches

of

vacuum

is re-

quired

to

actuate

the

parking brake

vacuum motor.

Do not

remove

any

of

the

vacuum hoses from the junction

block unless

the

junction block

is

being replaced,

as the

plastic nipples

are thin

and

very brittle

and

damage

may result.

If a

minimum reading

is

not

present when checking each

of

the

aforementioned components,

they must

be

replaced.

ROAD TEST

A road test should

be

conducted

only when

the

operator

is

sure

the

brakes will stop

the

vehicle.

During

a

road test, apply

the

vehicle brakes

at a

road speed

of

20

mph for all

problem conditions

listed

in

Figs.

9 and 10

with

the ex-

ception

of

those resolved

in the

brake

system tests

and

brake chatter.

To

check

for

brake chatter

or

surge,

ap-

ply

the

brakes lightly

at 50

mph.

For

each

of the

symptoms encountered

check

and

eliminate

the

caused which

are listed

in

Figs.

9

and

10.

If

the

road test reveals

one or

more problem conditions listed Figs.

9

and 10,

correct

all

malfunctions

of

the vacuum system, brake booster

and hydraulic system prior

to

remov-

ing brake drums, brake calipers,

brake shoes

and

linings

or

backing

plates.

COMMON ADJUSTMENTS AND REPAIRS

PARKING BRAKE LINKAGE

ADJUSTMENT

Check

the

parking brake cables

when

the

brakes

are

fully released.

If

the

cables

are

loose, adjust them

as

follows:

1.

Fully release

the

parking brake

pedal

by

pulling

the

release lever,

or

on

a

vacuum release pedal

by

pushing

down

the

manual release lever.

2.

Depress

the

parking brake pedal

until

it is

engaged

in the

first notch

of

the control,

3.

Raise

the

vehicle. With

the

transmission

in

neutral, turn

the

adjusting

nut

forward against

the

equalizer

(Fig. 3)

until

a

moderate

drag

is

felt when turning

the

rear

wheels (approximately

100 lbs of

force

at the

outside diameter

of the

tire

is

required

to

turn

the

REAR WHEEL CABLE-2A809

EQUALIZER-TO-CONTROL CABLE-2A815

RiARWHiiUCAIUi=2A63i

ADJUSTING

NUT

HI

537-

A

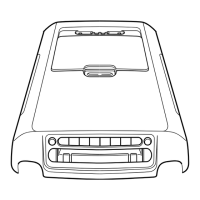

rear FIG. 3—Parking Brake Adjustment

Loading...

Loading...