2-6

GROUP 2 - Brakes

last. Depress the brake pedal slowly

to build line pressure until the pres-

sure differential valve is moved to a

centralized position and the brake

warning light goes out; then, immedi-

ately tighten the outlet port tube nut.

2.

Check the fluid level in the mas-

ter cylinder reservoirs and fill them to

within 1/4 to 1/2 inch of the top with

the specified brake fluid, if necessary.

3.

Turn the ignition switch to the

OFF position.

4.

Before driving the vehicle, check

the operation of the brakes and be sure

that a firm pedal is obtained.

CLEANING AND INSPECTION

DISC BRAKES

1.

Remove the wheel and tire

and the shoe and lining assemblies

as outlined in Part 2-2, Section 2.

2.

Make thickness measurements

with a micrometer across the thinnest

section of the shoe and lining. If the

assembly has worn to a thickness of

0.230-inch (shoe and lining together)

or 0.030-inch (lining material only)

at any one of three meauring locations

or if lining shows evidence of brake

fluid contamination, replace all (4)

shoe and lining assemblies on both

front wheels.

3.

Check the caliper to spindle at-

taching bolts torque. Torque them to

specification, if required.

4.

To check rotor runout, first

eliminate the wheel bearing end play

by tightening the adjusting nut. After

tightening the nut, check to see that

the rotor can still be rotated.

5.

Clamp a dial indicator to the

caliper housing so that the stylus

contact the rotor at a point approxi-

mately 1 inch from the outer edge.

Rotate the rotor and take an indica-

tor reading. If the reading exceeds

0.002 inch total lateral runout on the

indicator, replace or resurface the disc

brake rotor. The following require-

ment must be met when resurfacing

disc brake rotors:

Rotunda Disc Brake Attachment

FRE-2249-2 is the only approved tool

to be used to refinish the disc brake

rotors.

The step-by-step resurfacing

procedure provided with the tool

must be adhered to.

The finished braking surface of the

rotor must be flat and parallel within

0.0007 inch; lateral runout must not

exceed 0.002 inch total indicator

reading, and the surface finish of the

braking surface are to be 85/15

micro inches. The minimum limiting

dimension (Fig. 8) from the inboard

bearing cup to the inboard rotor face

(dimension B) and the outboard rotor

surface and the inboard bearing cup

(dimension A), must be observed

when removing material from the

rotor braking surfaces.

When the runout check is finished

HI

532-A

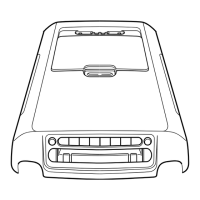

FIG.

8—Disc

Brake Rotor Service

Limits.

be sure to adjust the bearings as out-

lined in Group 3, in order to prevent

bearing failure.

6. Check the rotor for scoring.

Minor scores can be removed with a

fine emery cloth. If the rotor is ex-

cessively scored, refinish it as outlined

in step 5 or replace the rotor, if re-

quired.

7.

Visually check the caliper if

excess leakage is evident, it should be

replaced. Slight leakage around the

piston or a seized piston indicates

the need for removal and disas-

sembly.

8. If upon disassembly the caliper

if found to be distorted or damaged,

or if the cylinder bores is scored or

excessively worn, replace the assem-

bly.

9. Check the brake hoses for signs

of cracking, leaks or abrasion. Re-

place them if necessary.

DRUM BRAKES

1.

Remove the wheel from the

drum, and remove the drum as out-

lined in Part 2-2, Section 2.

2.

Brush all dust from the backing

plates and interior of the brake

drums.

3.

Inspect the brake shoes for ex-

cessive lining wear or show damage.

If the lining is worn within 1/32 inch

of the rivet heads or if the shoes are

damaged, they must be replaced. Re-

place any lining that had been con-

taminated with oil, grease or brake

fluid. Replace lining in axle sets.

Prior to replacement of lining, the

drum diameter should be checked to

determine if oversize linings must be

installed.

4.

Check the condition of brake

shoes,

retacting springs, hold-down

springs, and drum for signs of over-

heating. If the shoes have a slight

blue coloring, indicating overheating,

replacement of the retracting and

hold-down springs is strongly recom-

mended. Overheated springs lose their

pull and could cause the new lining

to wear prematurely, if they are not

replaced.

5. If the vehicle has 30,000 or more

miles of operation on the brake lin-

ings or signs of overheating are pres-

ent when relining brakes, the wheel

cylinders should be disassembled and

inspected for wear and entrance of

dirt into the cylinder. The cylinder

cups should be replaced., thus avoid-

ing future problems.

6. Inspect all other brake parts and

replace any that are worn or dam-

aged.

7.

Inspect the brake drum and, if

necessary, refinish. Refer to Part 2-2,

Section 4 for refinishing.

BOOSTER UNIT

Check the booster operation as

noted in Part 2-1, Section 1, Power

Brake Functional Test. If the brake

booster is damaged or defective, re-

place it with a new booster. The

brake booster is serviced only as an

assembly.

Loading...

Loading...