2-10

GROUP 2-Brakes

DISC BRAKES

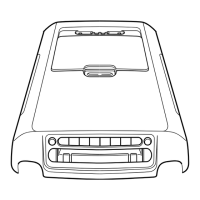

RETURN SPRING

(SECONDARY)

RETAINER

PRIMARY SYSTEM BRAKE

FLUID RESERVOIR

RETURN SPRING (PRIMARY)

BOOT

PUSH ROD

(SECONDARY)

BRAKE OUTLET

PORT

SECONDARY PISTON

ASSEMBLY

(PRIMARY)

BRAKE OUTLET

PORT

PRIMARY PISTON

ASSEMBLY

FIG.

1

— Dual-Master Cylinder-

Typical

master cylinders is porportioned to

fulfill the requirements of each of the

two independent hydraulic brake sys-

tems (Fig. 1).

If a failure of the rear (secondary)

brake system should occur, initial

brake pedal movement causes the un-

restricted secondary piston to bottom

in the master cylinder bore. Primary

piston movement displaces hydraulic

fluid in the primary section of the

dual-master cylinder to actuate the

front brake system.

Should the front (primary) brake

system fail, initial brake pedal move-

ment causes the unrestriced primary

piston to bottom out against the sec-

ondary piston. Continued downward

movement of the brake pedal moves

the secondary piston to displace hy-

draulic fluid in the rear brake system,

actuating the rear brakes. On disc

brake equipped vehicles, the pressure

differential valve will move to the low

pressure area of the front system. This

movement uncovers the rear brake

system outlet passage and provides a

direct passage from the rear inlet pas-

sage to the outlet passage, bypassing

the proportioning valve. This provides

full hydraulic pressure to the rear

brake system.

The increased pedal travel and the

increased pedal effort required to

compensate for the loss of the failed

portion of the brake system provides

a warning that a partial brake system

failure has occurred. When the igni-

tion switch is turned to the start posi-

tion, a dual-brake warning light pro-

vides a visual indication the warning

lamp is functional. When the ignition

switch is turned to the ON or ACC

position, a dual-brake warning light

on the instrument panel also provides

a visual indication if one portion of

the dual-brake system has become

inoperative.

Should a failure of either the front

or rear brake hydraulic system occur,

the hydraulic fluid pressure differen-

tial resulting from the pressure loss

of the failed brake system forces the

valve toward the low pressure area to

illuminate the brake warning light

(Fig. 2).

A mechanically operated electrical

switch is located on the side of the

pressure differential valve assembly

between the front and rear brake sys-

tem inlet ports. The inner-end of the

spring loaded switch plunger con-

tacts the bottom of a tappered shoul-

der groove in the center of the valve

(Fig. 2). O-ring seals are retained in

seal ring lands near each end of the

valve.

Should a failure of the rear brake

H 1545-A

system occur, hydraulic fluid pres-

sure in the rear brake system would

drop.

During brake pedal operation

the fluid pressure build-up of the front

brake system forces the valve to move

toward the low pressure area, or to-

ward the rear brake system outlet

port (Fig. 2). Movement of the dif-

ferential valve forces the switch plun-

ger upward over the tapered shoulder

of the valve to close the switch electri-

cal contacts and light the dual brake

warning lamp, signalling a brake sys-

tem failure.

In the event a front brake system

failure should occur, greater pressure

from the rear brake system during

brake pedal operation forces the valve

forward, moving the switch plunger

upward onto the valve ramp to light

the brake system warning lamp. How-

ever, failure of either the front or

rear system does not impair opera-

tion of the other brake system.

DISC BRAKES

Disc brakes are available as op-

tional equipment for the front wheels.

The hydraulic brake system employs

single anchor, internal expanding and

self-adjusting drum brake assemblies

on the rear wheels of vehicles with

disc brakes, and on front and rear

wheels of all others.

Loading...

Loading...