2-18

GROUP 2 - Brakes

screw fitting.

4.

Front wheel bearing end play is

critical and must be within specifica-

tions.

5.

Be sure the vehicle is centered

on the hoist before servicing any front

end components, to avoid bending or

damaging the rotor splash shield on

full right or left wheel turns.

6. The proportioning valve should

not be disassembled or adjustments

attempted on it.

7.

Riding of the brake pedal (com-

mon on left foot applications) should

be avoided during vehicle operation.

8. The wheel and tire must be re-

moved separately from the brake ro-

tor, unlike drum brakes where the

wheel, tire and drum are removed as

a unit.

9. The caliper assembly must be

removed from the spindle prior to re-

moval of the shoe and lining assemb-

lies.

10.

Do not attempt to clean or

restore oil or grease soaked brake

linings. When contaminated linings

are found, brake linings must be re-

placed in complete axle sets.

REMOVAL

1.

Remove the wheel and tire from

the hub. Be careful to avoid damage

or interference with the bleeder screw

fitting.

2.

Remove the two bolts that at-

tach the caliper to the spindle.

3.

To facilitate removal and in-

stallation of the shoe and lining as-

semblies, the piston must be pushed

into its bore. Apply a steady in-

ward pressure against the inner shoe

and lining assembly. Maintain the pres-

sure for at least a minute.

4.

Slide the two outer shoe re-

taining clips off the retaining pins

(Fig. 18).

5.

Remove the two retaining pins

from the outer shoe, then remove the

shoe from the stationary caliper.

6. Slide the inner brake shoe

outward until it is free of the hold-

down springs, then remove the brake

shoe.

7.

Remove the caliper guide pins

and stabilizer attaching bolts, then

remove the stabilizers.

8. Remove the guide pin insulators

from the anchor plate.

INSTALLATION

When new shoe and lining assem-

blies are being installed to replace

worn linings it will be necessary to

push the piston all the way into the

caliper bore. This will displace fluid

from the caliper into the master cyl-

inder reservoir. Check the primary

(front) brake system reservoir level

and remove fluid to approximately

half full before replacing brake shoes.

This will prevent overflow. Do not

reuse the removed fluid.

1.

Install new caliper guide pin

insulators in the anchor plate.

2.

Position the caliper assembly

in the anchor plate.

3.

Apply the specified fluid to

the caliper guide pins and install

them loosely in the anchor plate.

Be sure the guide pins are free of

oil, grease or dirt.

4.

Position the outer brake on

the caliper and install the two re-

taining pins and clips.

5.

Install the inner brake shoe

so that the ears of shoe are on top

of the anchor plate bosses and under

the shoe hold-down springs.

6. Position the shoe and lining

assemblies so that the caliper assem-

bly can be placed over the rotor.

Rotate a hammer handle between the

linings to provide the proper clear-

ance.

7.

Install the caliper assembly

over the rotor and on the spindle.

Install the two caliper attaching

bolts,

and torque them to specifica-

tions.

The upper bolt must be tighten-

ed first. Install the safety wire and

twist the ends at least five turns.

8. With moderate pressure applied

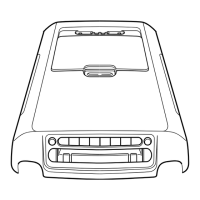

SPINDLE

CALIPER PARTS

2B120 R.H.

2B121 L.H.

2B296

20310-S

34806-S

CALIPER ASS'Y.

2B118 R.H.

2B119 L.H.

INSULATOR

CL.P

2B2

"

2B164

INNER BEARING

CONE AND ROLLER

1201

ANCHOR PLATE

2B293 L.H.

2B292 R.H.

HUB

CUP

CONE AND ROLLER

1216

ROTOR SPLASH SHIE

2K004'R.H.

2K005.LH,

ADJUSTING NUT

374504>S

GREASE CAP

1131

COVER-1130

H 1571-A

FIG. 78—Disc Brake Disassemblied

Loading...

Loading...