PART 2-2 - Brake System

2-23

being replaced, remove the axle shaft

from the applicable rear axle as out-

lined in Group 4, Part 4-2—Rear

Axle, Section 2. Remove the backing

plate and gasket.

If the front backing plate is being

replaced, remove the bolts and nuts

that secure the backing plate to the

front wheel spindle and remove the

plate and gasket.

INSTALLATION

If a rear backing plate is to be re-

placed, position a new rear backing

plate and gasket on the attaching

bolts in the axle housing flange. In-

stall the rear axle shaft for the appli-

cable rear axle. Refer to Group 4,

Part 4-2—Rear Axle, Section 2 for the

proper installation procedure.

1.

If the front brake backing plate

is to be replaced, position a new front

backing plate and gasket to the wheel

spindle and install the attaching bolts

and nuts.

2.

Install the wheel cylinder and

connect the brake line as outlined in

this section.

3.

Install the brake shoe and ad-

juster assemblies as outlined in this

section. On a rear brake, connect the

parking brake cable to the lever.

4.

Adjust the brake shoes (Section

2),

and install the brake drums and

wheels. Bleed the brake drums and

wheels. Bleed the brake system and

centralize the differential valve as

outlined in Part

2-1,

Section 2.

HYDRAULIC LINES

Steel tubing is used throughout the

brake system with the exception of

the flexible hoses at the front wheels

and at the rear axle housing brake

tube connection (Figs. 19 and 21).

Always bleed the applicable pri-

mary or secondary brake system after

primary or secondary brake system

hose or line replacement. Centralize

the brake system after bleeding the

system.

BRAKE TUBE

REPLACEMENT

If a section of the brake tubing be-

comes damaged, the entire section

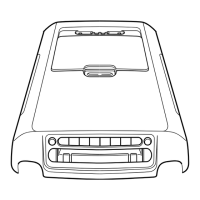

DISC BRAKE

OUTLET TUBE

REAR BRAKES

BUSHING

\ SHAFT (AUTOMATIC

V TRANSMISSION)

I

BLFEDER SCREW

SPACER STUD

CLUTCH

PEDAL

ASSEMBLY

BUSHING

NUT

LOCK WASHER

/

MASTER CYLINDER PUSH ROD

STOP LITE BRAKE PEDAL

SWITCH ASSEMBLY

H 1491-C

FIG. 22— Master Cylinder Installation— Standard Brakes

should be replaced with tubing of the

same type, size, shape, and length.

Copper tubing should not be used in

a hydraulic system. When bending

brake tubing to fit underbody or rear

axle contours, be careful not to kink

or crack the tube.

All brake tubing should be double

flared properly to provide good leak-

proof connections. Clean the brake

tubing by flushing with clean brake

fluid before installation.

When connecting a tube to a hose,

tube connector, or brake cylinder,

tighten the tube fitting nut to speci-

fied torque with Milbar tool 1112-144

or equivalent.

BRAKE HOSE

REPLACEMENT

A flexible brake hose should be re-

placed if it shows signs of softening,

cracking, or other damage.

When installing a new front brake

hose,

position the hose to avoid con-

tact with other chassis parts. Place a

new copper gasket over the hose fit-

ting and thread the hose assembly in-

to the front wheel cylinder. Engage

the opposite end of the hose to the

bracket on the frame. Install the

horseshoe-type retaining clip, and

connect the tube to the hose with the

tube fitting nut (Figs. 19 and 21).

A rear brake hose should be in-

stalled so that it does not touch the

muffler outlet pipe or shock absorber.

Place a new gasket over the rear

hose fitting and thread the hose into

the rear brake tube connector. En-

gage the front end of the hose to the

bracket on the frame. Install the

horseshoe-type retaining clip, and

connect the tube to the hose with the

tube fitting nut.

REMOVAL AND INSTALLATION

DUAL MASTER CYLINDER-

STANDARD BRAKES

REMOVAL

1.

Working from inside the vehicle

below the instrument panel, disconnect

the master cylinder push rod from the

brake pedal (Fig. 22).

2.

Disconnect the stoplight switch

wires at the connector. Remove the

spring retainer. Slide the stop light

switch off the brake pedal pin just

far enought to clear the end of the pin,

then lift the switch straight upward

from the pin. Use care to avoid switch

Loading...

Loading...