Wheels

spindle.

8.

If the inner and/or outer bear-

ing

cup(s) were removed, install the

replacement

cup(s) in the hub with

the tool shown in Fig, 5.

Be sure to

seat the cups properly in the hub.

9.

Pack the inside of the hub with

specified wheel bearing grease. Add

lubricant to the hub only until the

grease is flush with the inside diame-

ter of both bearing cups (Fig. 6).

10.

All old grease should be com-

pletely cleaned from the bearings and

surrounding surfaces before repacking

them with new grease

(CIAZ-

19590-B). The new lithium base

grease is not compatible with sodium

base grease which may have been

present on the bearing surfaces. Pack

the bearing cone and roller assemblies

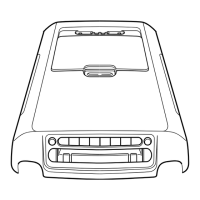

FIG. 4-Removing Front Wheel

Bearing Cups-Disc (Drum-Type

Similar)

INNER CUP OUTER CUP

INSTALLATION INSTALLATION

FIG. 5-Installing Front Wheel

Bearing Cups-Drum

with wheel bearing grease. A bearing

packer is desirable for this operation.

If a packer is not available, work as

much lubricant as possible between

the rollers and cages. Lubricate the

cone surfaces with grease.

11.

Place the inner bearing cone

and roller assembly in the inner cup.

Apply a light film of grease to the

lip(s) of the grease retainer and install

the new grease retainer with the rev-

erse end of the tool shown in Fig. 5.

Be sure that the retainer is properly

seated.

12.

Adjust the brake shoes as out-

lined in Group 12.

13.

Install the wheel, hub, and

drum assembly on the wheel spindle.

Keep the hub centered on the spindle

to prevent damage to the grease re-

tainer or

the.spindle threads.

14.

Install the outer bearing cone

and roller assembly and the flat wash-

er on the spindle, then install the ad-

justing nut (Fig.

1).

15.

Adjust the wheel bearings as

outlined in Section 2, and install a

new cotter pin. Bend the ends of the

cotter pin around the castellations of

the nut lock to prevent interference

with the radio static collector in the

grease cap. Install the grease cap.

16.

Install the hub cap or wheel

cover.

DISC BRAKES

1.

Raise the vehicle until the wheel

FIG. 6-Front Wheel Hub

Lubrication

and tire clear the floor.

2.

Remove the wheel cover or hub

cap from the wheel.

3.

Remove the wheel and tke f~om

the hub and rotor.

4.

Remove 2 bolts and washers

that attach the caliper to the spindle.

Remove the caliper from the rotor

and wire it to the underbody to pre-

vent damage to the brake hose.

5.

Remove the grease cap from the

hub. Remove the cotter pin, nut lock,

adjusting nut, and flat washer from

the spindle. Remove the outer bearing

cone and roller assembly (Fig. 2).

6.

Pull the hub and rotor assembly

off the wheel spindle.

7.

Remove and discard the old

grease retainer and the inner bearing

cone and roller assembly from the

hub.

8.

Clean the lubricant off the inner

and outer bearing cups with solvent

and inspect the cups for scratches,

pits, excessive wear, and other dam-

age. If the cups are-worn or damaged,

remove them with Tool

T69L- 1102-A

(Fig.

4).

9.

Thoroughly clean the inner and

outer bearing cones and rollers with

cleaning solvent, and dry them thor-

oughly.

Do not spin the bearings dry

with compressed air.

Inspect the cones and rollers for

wear or damage, and replace them if

necessary. The cone and roller assem-

blies and the bearing cups should be

replaced as a set if damage to either

is encountered.

10.

Thoroughly, ,-clthn the spindle

and the

inside..,of"ihe hub with solvent

to remove

.@old lubricant.

Cover,

,;the spindle with a clean

cloth,

aid

brush all loose dust and

dirt from the dust shield.

To

prevent

getting dirt on the spindle carefully

remove the cloth from the spindle.

11.

If the inner and/or outer bear-

ing

cup(s) were removed, install the

replacement

cup(s) in the hub with

the tools shown in Fig.

7.

Be sure to

seat the cups properly in the hub.

12.

Pack the inside of the hub with

the specified wheel bearing grease.

Add lubricant to the hub only until

the grease is flush with the inside di-

ameter of both bearing cups.

It

is important that all old grease

be removed from the wheel bearings

and surrounding surfaces because the

new Lithium base grease

ClAZ-

19590-B

is not compatible with Sodi-

um base grease which ,may already be

present on the bearing surfaces.

13.

Pack the bearing cone and roll-

er assemblies with wheel bearing

grease. A bearing packer is desirable

Loading...

Loading...