070.650-IOM (AUG 2015)

Page 19

SGC ROTARY SCREW COMPRESSOR

INSTALLATION

it is imperative that the discharge temperature be at least

30°F higher than the discharge dew point temperature for

the gas. Run Coolware with the “Water Saturated” block

checked to get the discharge dew point temperature for

your application. Oil temperatures as high as 170°F can be

used to achieve the necessary discharge temperature to

prevent moisture from condensing in the oil separator. In

special applications, oil temperatures up to 250°F can be

possible with high dew point temperatures. Consult Frick

engineering to address these special applications or for ad-

ditional natural gas compression information.

The main oil injection line that is connected to port SM-1

must have a regulating valve to permit adjustment of the

oilowtomaintainthedesireddischargetemperatureat

all times.

The use of a three-way mixing valve is recommended to

keep the oil temperature in the normal range of 120° -

140°F. The valve will provide warm oil to the compressor

quickly, reducing the pressure drop caused by cold, viscous

oil.Thisensuresproperoilowandtemperatureoverthe

full range of operating conditions.

OIL FILTER(S)

Use of lter elements other than Johnson Controls-Frick

must be approved in writing by Johnson Controls-Frick

engineeringorawarrantyclaim maybe denied. Oil lter

specicationshouldbenohigherthanβ

10

= 75 with β

6

= 75

preferred. If the oil analysis shows particle counts exceed-

ingXX/XX/19perISO4406cleanlinesscode,alterchange

is required. If particle counts do not come down, an oil

change is required.

OIL HEATER(S)

Your package must be equipped with oil heaters that provide

sufcient heat to prevent condensation from occurring

during shutdown cycles.

COMPRESSOR OIL

WARNING

DO NOT MIX OILS of different brands, manufacturers,

or types. Mixing of oils can cause excessive oil foam-

ing, nuisance oil level cutouts, oil pressure loss, gas or

oil leakage and catastrophic compressor failure. Cool-

Ware will select a specic Frick oil for the refrigerant

being used. Depending on the application, a different

oil can be selected provided it is of the proper viscos-

ity and is compatible with the refrigerant and com-

pressor elastomers.

OIL PUMP

If your SGC compressor application requires an oil pump, it

is recommended that a strainer be mounted upstream to

protect it. Frick supplied pumps are a positive displacement

gear type that must have a safety relief valve to ensure the

oil pressure will not be more than 50 psi above compressor

discharge pressure for all models.

CAUTION

If oil pressure exceeds 55 PSI above compressor dis-

charge it could cause catastrophic compressor failure

due to male axial bearing failure. See CoolWare

™

for

your application’s requirements.

COMPRESSOR

COMPRESSOR ROTATION IS CLOCKWISE WHEN FACING

THE END OF THE COMPRESSOR SHAFT

Conrmmotorwillrotatethecompressorclockwisebefore

installing the coupling.

CAUTION

To prevent injury or damage to components, and for

complete details regarding pressurized refrigerant vapor

transfer and recovery, see the current Installation-

Operation-Maintenance Manual for your unit.

MOTOR MOUNTING USING TUNNEL

For specic instruction about motor mounting using a

tunnel use publication 070.660-SM - Bare Rotary Screw

Compressor Replacement.

NOTICE

Refer to the Bare Rotary Screw Compressor Replacment

manual, Frick publication 070.660-SM for motor

mounting instructions.

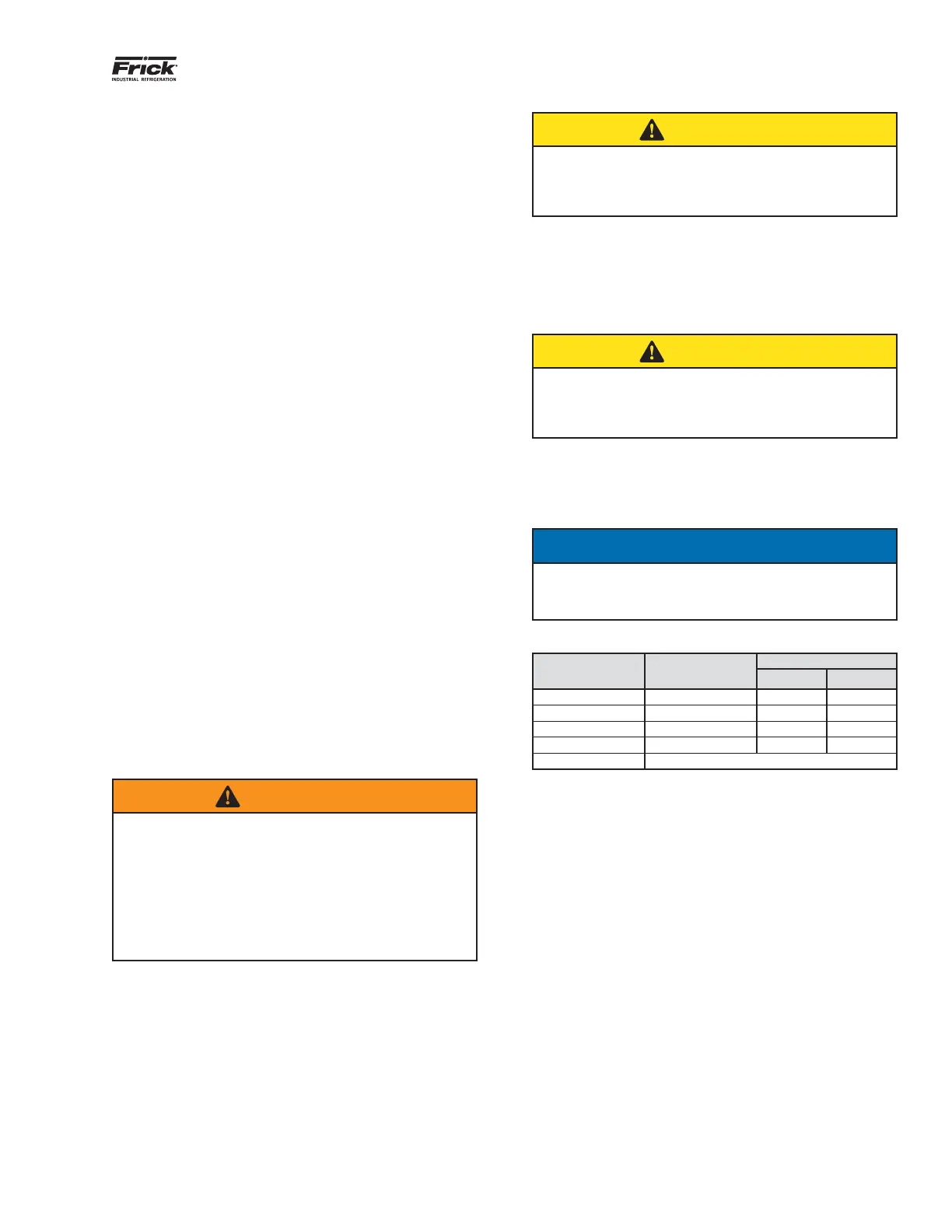

Table 4. Motor Tunnel Bolt Torque

Compressor

Model

Screw Size

Torque

ft-lb NM

SGC 19XX M12 X 1.75 58 79

SGC 23XX M12 X 1.75 58 79

SGC 28XX M16 X 2.0 144 195

SGC 35XX M20 X 2.5 260 353

SGX 40XX Not Applicable

MOTOR MOUNTING (FOOT MOUNTED ONLY)

1. Thoroughly clean the motor feet and mounting pads of

grease,burrs,andotherforeignmattertoensurerm

seating of the motor.

2. Attach the motor to the base using bolts and motor

raising blocks, if required.

3. Weld the four kick bolts (not included with compressor)

into place so that they are positioned to allow

movement of the motor feet.

4. After the motor has been set, check to see that the

shafts are properly spaced for the coupling being used.

Check the appropriate Dimensional Outline drawing

for the minimum clearance required between the shaft

ends to change the shaft seal.

COMPRESSOR/MOTOR COUPLING REQUIREMENTS.

SGC/SGX compressors are arranged for direct motor

driveandrequirea exibledrivecouplingtoconnectthe

compressor to the motor.

If you are using the Johnson Controls – Frick motor mount,

the mount is machined to ensure that motor to compressor

Loading...

Loading...