6

ENGLISH

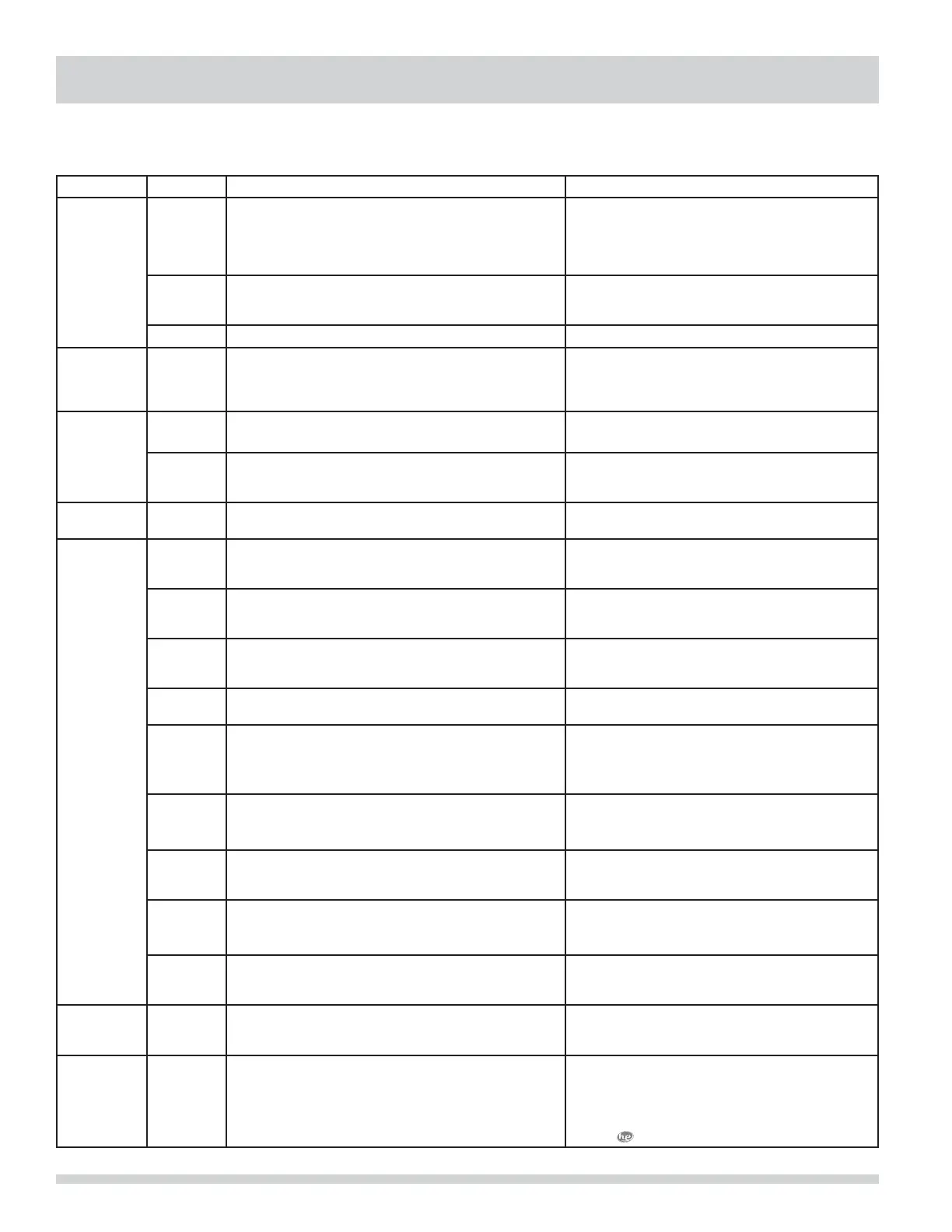

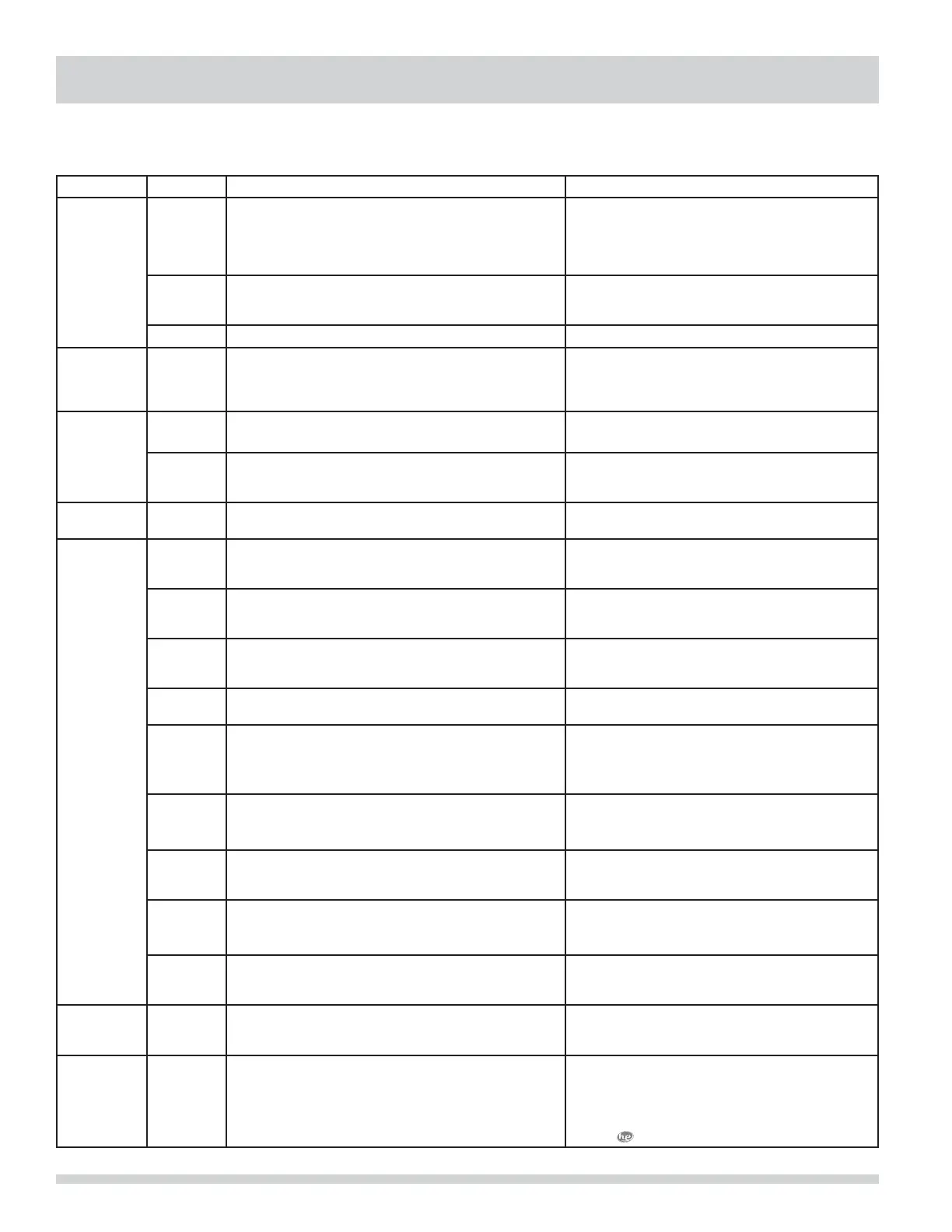

Error Code Chart

Alarm Family Error Code Fault Condition Possible Fault

E10

E11 fi ll time too long • water tap closed

• water fl ow rate too low

• pressure sensor defective

• air tube kinked, leaking

• water inlet valve defective

E13 unexpected water loss • siphoning - wrong drain pipe position

• drain pump defective

• wash tub leaking

E17 load out-of-balance • load unbalanced during spin phase

E20

E21 water not pumping out fast enough • drain pipe blocked

• drain pump defective

• pressure sensor defective

• wiring or main board defective

E30

E31 electronic pressure switch failure

frequency of pressure sensor not in range (36-46) KHz

• pressure sensor defective

E35 pressure sensor indicates water overfi ll • water inlet valve defective

• air tube kinked

• wiring or board defective

E40

E42 lid lock device failure • lid lock device defective

• wiring or board defective

E50

E50 motor fault:

an open circuit phase or rotor looses synchronization

• wiring problem

• motor defective

• motor control board defective

E55 closed loop mode fault:

no EMF feedback from motor

• wiring problem

• motor defective

• motor control board defective

E56 clutch jiggle failure:

can’t execute the required motor jiggle

• clutch position not aligned

• clutch defective

• wiring or board defective

E57 high current on inverter, MCE gate kill:

IGBT module problem

• short circuit of IGBT module

• motor control board defective

E59 incongruence between real motor speed and expected

motor speed

zero crossing error:

power line frequency out of range

• motor control board defective

E5A high temperature on heat sink on control board

DC bus voltage failure:

DC bus voltage out of range (150V – 400V)

• low AC voltage input

• motor control board defective

• wiring defective

E5B low voltage fault:

the DC bus voltage has gone below 150V

• low AC voltage input

• motor control board defective

• wiring defective

E5C voltage too high on control board

over voltage fault:

the DC bus voltage has gone above 400V

• high AC voltage input

• motor control board defective

• wiring defective

EC4 clutch cam error:

can’t fi nd the required cam position

• clutch position not aligned

• clutch defective

• wiring or board defective

E90

E91 communication error between UI board and motor control

board

• wiring defective

• UI defective

• motor control board defective

EF0

EF2 too much suds causing overheating of motor

cannot reach target speed within estimated time

high current consumption during maximum spin

• too much suds

• too much load or mechanical strain on motor

• wiring problem between motor and board

In the future, reduce detergent dose or use a low

sudsing

detergent.

Loading...

Loading...