Options

General The options listed below are available with all power source variants.

Machine inter-

face

The machine interface connects the power source to the machine control. The

following signals can be transmitted across the machine interface:

Signal input: Start of welding / end of welding

-

Signal input for a floating contact (sensor, relay, etc.) between pin X1:1 and

pin X1:2

-

The machine control signal input is processed by the power source in the

same way as a welding torch signal input. Ensure that the correct mode is set

(2-step or 4-step)

-

Use gold-plated contacts for optimum signal transmission

Signal output: Current flow signal

-

Floating contact between pin X1:3 and pin X1:4

NOTE!

The machine interface isolates the welding circuit up to a maximum of 500 V

DC.

To ensure reliable isolation from the welding circuit, use a relay with an insulation

voltage greater than 1500 V DC.

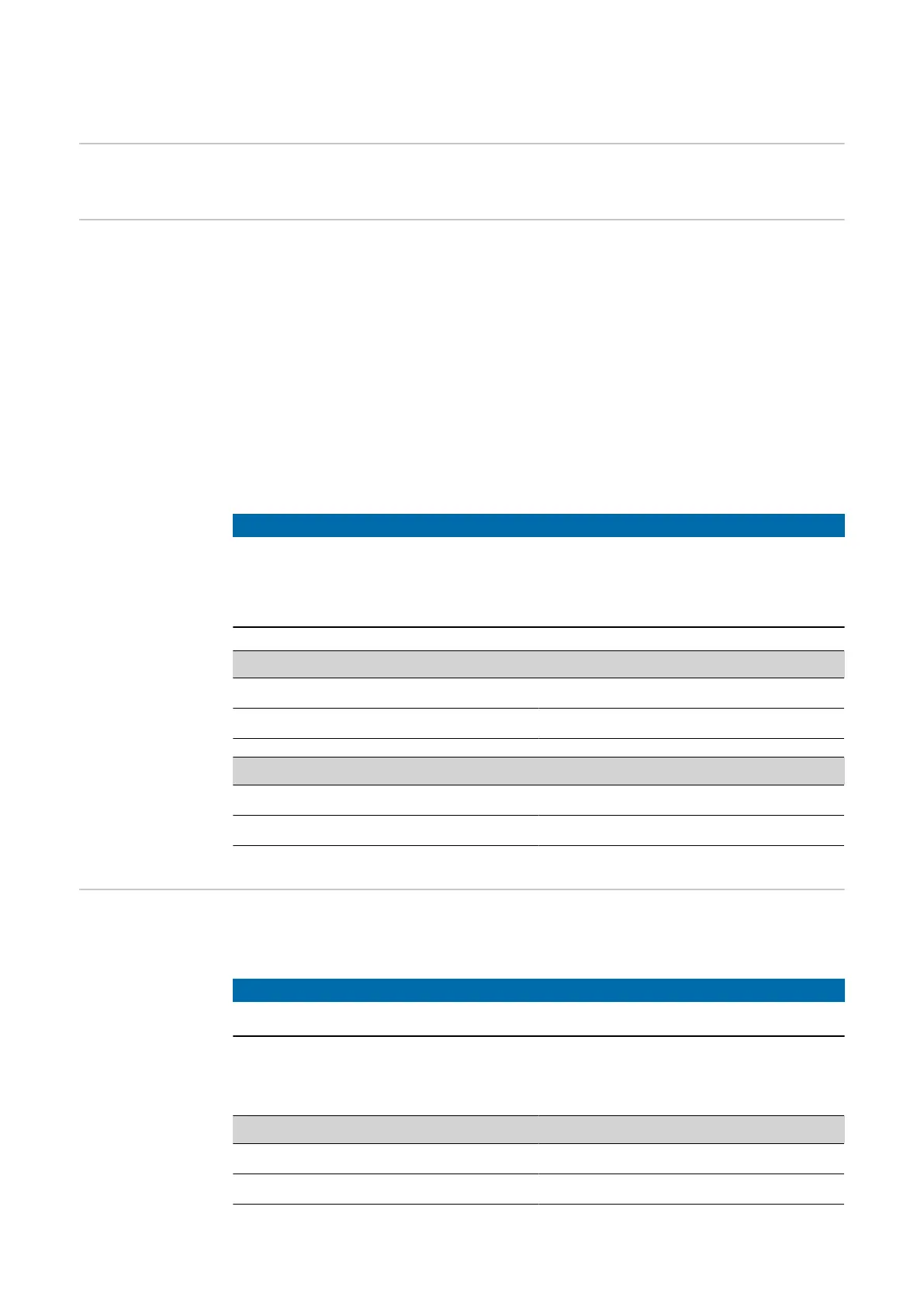

Technical data - start/end of welding signal input

U

maxAC

5 V

I

max

4 mA

Technical data - current flow signal output

U

max

24 V

I

max

20 mA

Gas preheater

CO2 connection

External gas preheaters for gas pressure regulators can be connected to the gas

preheater CO2 connection. Gas preheaters have a 36 V supply.

NOTE!

Voltage is only supplied to gas preheaters during welding operations.

The power of the gas preheaters must not exceed 150 W.

The gas preheater supply is protected against overloads and short-circuits.

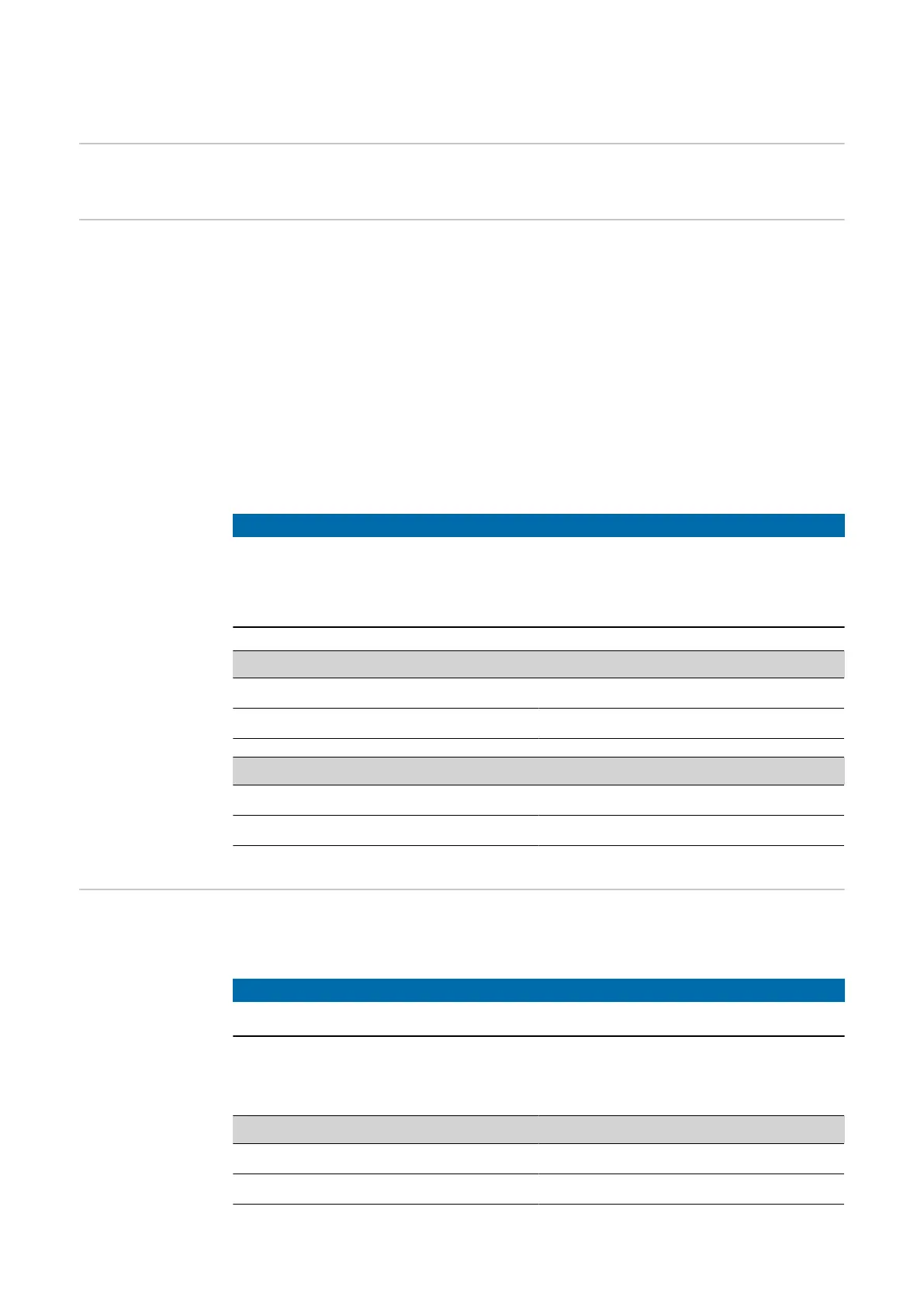

Technical data

U

A

36 V

AC

P

A, max

150 W

26

Loading...

Loading...