Instruction Manual

BUILT TO LAST | MANUFACTURED TO COMPLY | DESIGNED TO PROTECT

1

25

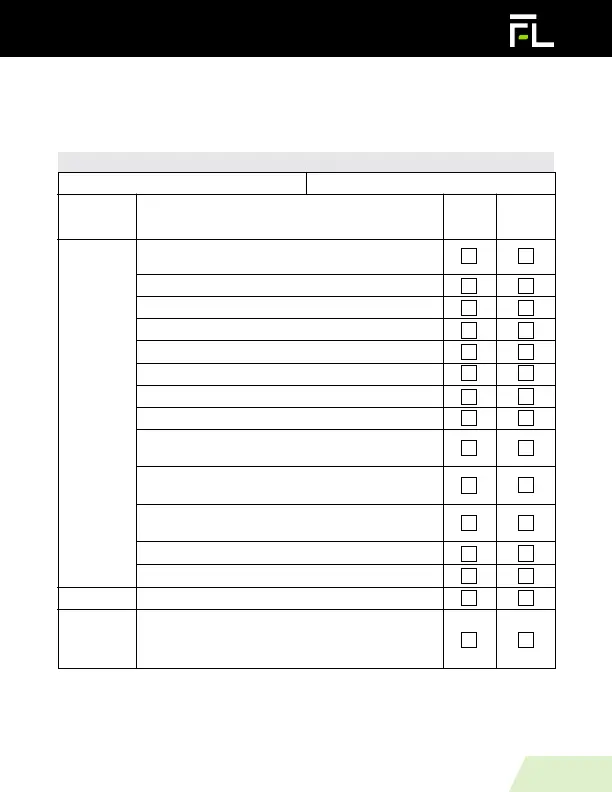

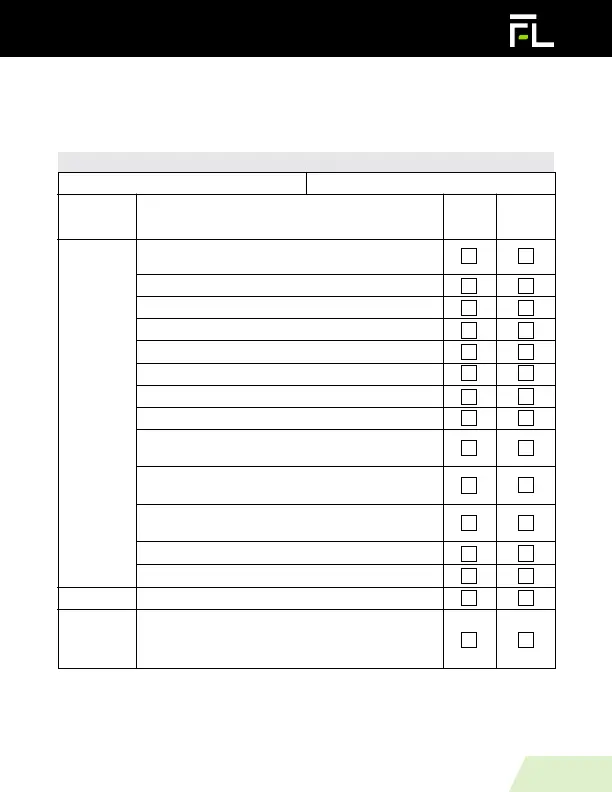

INSPECTION AND MAINTENANCE LOG

COMPONENTS:

ANCHORAGE:

PASS FAIL

INSPECTION DATE: INSPECTED BY:

Inspection: Prior to installation and prior to each use /

Inspection by a competent person is required every 6

months.

Inspect the Anchor for damage: Look for cracks, dents,

or deformities.

Inspect that all rotating components are working

properly.

Inspect that locking pin and safety pin are in place and

correctly used at all times.

Inspect that all plastic and rubber components are in

place.

Inspect that d-ring anchor is secure and in place.

Other.

Inspect the entire unit for corrosion.

Inspect that adjustable arm is sliding accordingly.

Inspect for any other unconformity.

Inspect for any missing parts (fasteners, etc.)

Inspect that no bolts are missing or lose.

Inspect for permanent deformation.

Inspect for bending or wear on loops.

LABELS

Inspect the Anchor for illegible labels.

Additional Personal Fall Arrest System (PFAS) equipment

(harness, SRL, etc) that are used with the Anchorage

System should be installed and inspected per the

manufacturer’s instructions.

PFAS AND

OTHER

EQUIPMENT

TRANSPORT: Ensure to transport product where it doesn’t beat up against other

products as this might cause damage to products and terminate the use of them.

Product also should not be transported with harmful substances or chemicals

as this might also compromised the integrity of the product.

MAINTENANCE, SERVICE, AND STORAGE

Loading...

Loading...