6

45

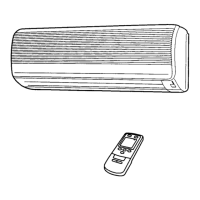

INDOOR UNIT SIDE

(1) Remove the electric component box.

Electric component box

Electric component box

Remove the four

tapping screws.

CAUTION

1 Do not remove the screws. If the stays

are removed, the electric component

box will fall.

2 If you use as “Floor console”, you must

remove screws and RFMs (2 positions).

(4) Wiring

1 Remove the cord clamp.

2 Process the end of the connection cords to the dimensions as shown

in the figure.

3 Connect the end of the connection cord fully into the terminal block.

Cord clamp

Cord clamp

(2) Pull out the electric component box.

Electric component box

(3) Remove the electric component box cover.

Electric component box cover

Remove the three tapping screws.

CAUTION

Be careful not to pinch the lead wires between the electric

component box and base.

Base

4 Fasten the connection cord with a cord clamp.

5 Fasten the end of the connection cord with the screw.

MOUNT THE COVER PLATE

AND THE INTAKE GRILLE

1. MOUNT THE COVER PLATE (RIGHT)

(1) Cut a pipe exit hole in the right plate. This is only when the pipe exits

from the right side. (This operation is not required when the protrusion

is on the top or rear.)

(2) Join the cover plates (right) and mount with the screw (ø4 × 10).

Cover plate (Right)

2. MOUNT THE COVER PLATE (LEFT)

Join the cover plates (left) and mount with the screw (ø4 × 10).

Cover plate (Left)

3. MOUNT THE INTAKE GRILLE

(1) Cut the r ight side of the intake grille. This is only when the pipe exits

from the right side.

(2) Inser t the hinges on the bottom of the intake grille into the holes in the

base assembly. Then mount the arms to the three areas on the top of

the intake grille.

A. Solid wire

Strip 25 mm (15/16")

Insulation

Loop

B. Strand wire

Strip 10 mm (3/8")

Round

terminal

Wire

Screw with

special washer

Round terminal

Terminal

board

Wire

Screw with

special washer

Round

terminal

HOW TO CONNECT WIRING TO THE TERMINALS

A. For solid core wiring

(1) Cut the wire end with a wire cutter or wire-cutting pliers, then strip

the insulation to about 25 mm (15/16") of expose the solid wire.

(2) Using a screwdriver, remove the terminal screw(s) on the terminal

board.

(3) Using pliers, bend the solid wire to form a loop suitable for the

terminal screw.

(4) Shape the loop wire proper ly, place it on the terminal board and

tighten securely with the terminal screw using a screwdriver.

B. For strand wiring

(1) Cut the wire end with a wire cutter or wire-cutting pliers, then strip

the insulation to about 10 mm (3/8") of expose the strand wiring.

(2) Using a screwdriver, remove the terminal screw(s) on the terminal

board.

(3) Using a round ter minal fastener or pliers, securely clamp a round

terminal to each stripped wire end.

(4) Position the round terminal wire, and replace and tighten the ter-

minal screw using a screwdriver.

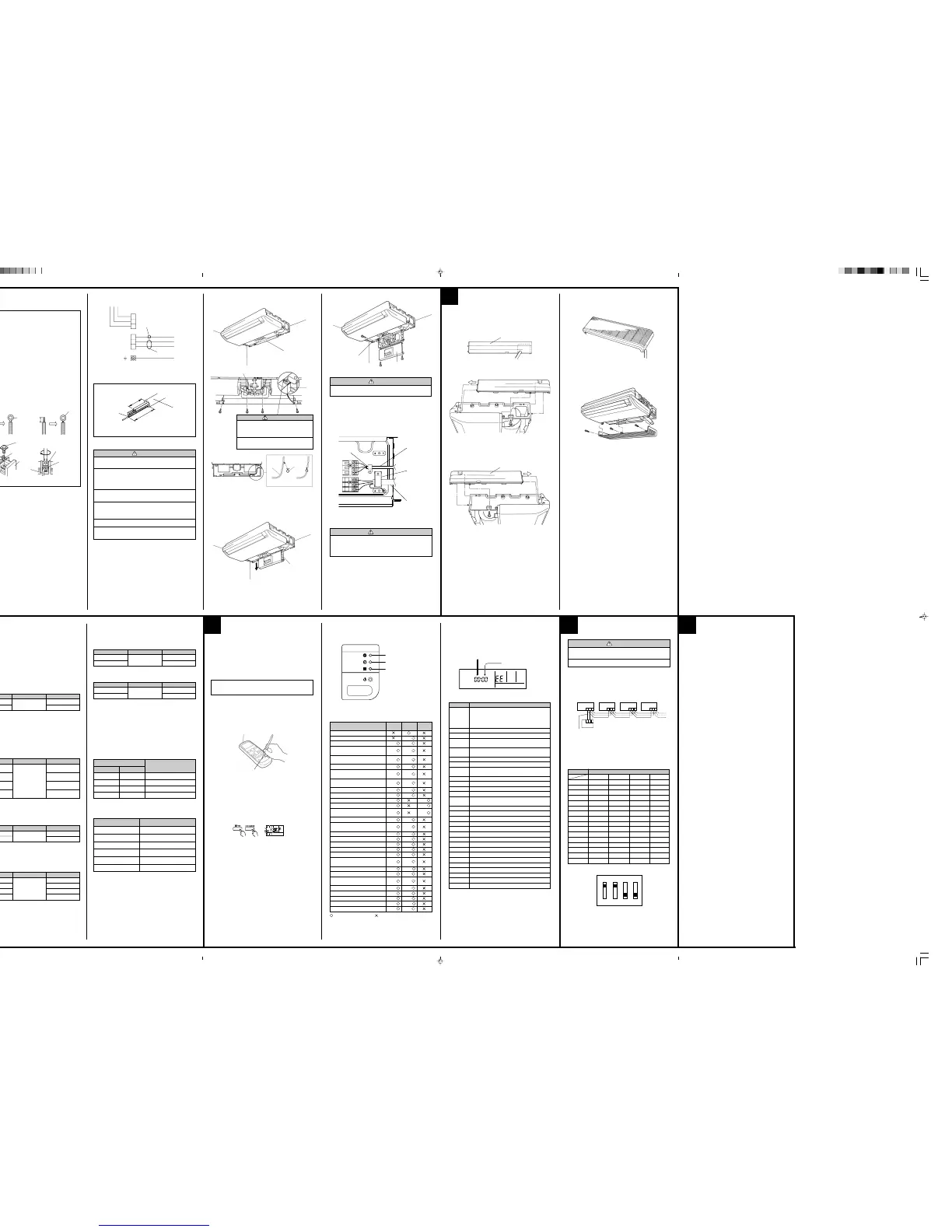

ELECTRICAL WIRING

1. CONNECTION DIAGRAMS

Wired remote controller (option)

Control line

Indoor unit

side terminal

Power line

Red

White

Black

Power supply cord

or connection cord

30 mm

60 mm or more

Earth wire

WARNING

1 Before starting work, check that power is not being

supplied to the indoor unit and outdoor unit.

2 Match the terminal board numbers and connection

cord colors with those of the outdoor unit.

Erroneous wiring may cause burning of the electric

parts.

3 Connect the connection cords firmly to the terminal

board. Imperfect installation may cause a fire.

4 Always fasten the outside covering of the connection

cord with the cord clamp. (If the insulator is chafed,

electric leakage may occur.)

5 Always connect the ground wire.

6 Install the remote controller wires so as not to be di-

rect touched with your hand.

3. CONNECTION OF WIRING

• Use a 4-core wire cord.

Keep the earth wire longer than the other wires.

Connection cord

(to outdoor unit)

Wired remote

controller cord

(option)

CAUTION

Do not bundle the remote controller cord, or wire the re-

mote controller cord in parallel, with the indoor unit con-

nection wire (to the outdoor unit) and the power supply

cord. It may cause erroneous operation.

2. CONNECTION CORD PREPARATION

(5) Floor console / Under celing select switch

1 This unit was set for use as a ceiling type at the factor y.

2 When using the unit as a floor type, perfor m the following settings in

FUNCTION SETTING. (Refer to 7 FUNCTION SETTING.)

Setting the Cooler Room Temperature Correction

→Setting Value “01”

Setting the Heater Room Temperature Correction

→Setting Value “01”

87

FUNCTION SETTING

• Follow the instructions in the Local Setup Procedure, which is supplied

with the remote control, in accordance with the installed condition. After

the power is turned on, perform the Function Setting on the remote

control.

• The settings may be selected between the following two: Function

Number or Setting Value.

• Settings will not be changed if invalid numbers or setting values are

selected.

Setting the Ceiling Height

• Select the setting values in the table below according to the height of

the ceiling. (The unit is factory-set to “00”.)

Setting Value

00

01

Setting Description

Standard

High ceiling

Function Number

20

Jumper wire

JM2

Connect

Connect

Disconnect

Disconnect

Remote control unit

signal code

A (Primary setting)

b

c

d

JM1

Connect

Disconnect

Connect

Disconnect

When using floor console installation, don't need to change the setting value.

Setting the Filter Sign

• The indoor unit has a sign to inform the user that it is time to clean the

filter.

• Select the time setting for the filter sign display interval in the table

below according to the amount of dust or debris in the room. (The unit

is factory-set to “00”.)

• If you do not wish the filter sign to be displayed, select the setting value

for “No indication”.

Setting Value

00

01

02

03

Setting Description

Standard

(400 hours)

Long interval

(1,000 hours)

Short interval

(200 hours)

No indication

Function Number

11

Setting the Cooler Room Temperature Correction

• Depending on the installed environment, the room temperature sensor

may require a correction. The settings may be selected as shown in the

table below. (The unit is factory-set to “00”.)

Setting Value

00

01

Setting Description

Standard

Lower control

Function Number

30

Setting the Heater Room Temperature Correction

• Depending on the installed environment, the room temperature sensor

may require a correction. The settings may be changed as shown in the

table below. (The unit is factory-set to “00”.)

Setting Value

00

01

02

03

Setting Description

Standard

Lower control

Slightly warmer control

Warmer control

Function Number

31

Setting Other Functions

• The following settings are also possible, depending on the operating

conditions. (The unit is factory-set to “00”.)

Auto Restart

Setting Value

00

01

Setting Description

Ye s

No

Function Number

40

Indoor Room Temperature Sensor Switching Function (Wired remote con-

troller only)

Setting Value

00

01

Setting Description

No

Ye s

Function Number

42

• If setting value is “00”, room temperature is controlled by the indoor unit

temperature sensor.

• If setting value is “01”, room temperature is controlled by either indoor

unit temperature sensor or remote control unit sensor.

[When using the wireless remote controller]

SWITCHING REMOTE CONTROL UNIT SIGNAL

CODES

• Confirm the setting of the remote control unit signal code and the printed

circuit board setting.

If these are not confirmed, the remote control unit cannot be used to

operate for the air conditioner.

When using floor console installation, change the setting value to “01”.

When using floor console installation, change the setting value to “01”.

TEST RUN

CHECK ITEMS

(1) Is operation of each button on the remote control unit normal?

(2) Does each lamp light nor mally?

(3) Do not air flow direction louvers operate normally?

(4) Is the drain nor mal?

(5) Is there any abnor mal noise and vibration during operation?

• Do not operate the air conditioner in the running state for a long time.

• Test running

When the air conditioner is run by pressing the remote control unit test

run button, the OPERATION and TIMER lamps flash slowly at the same

time.

[Using the wireless remote control]

• For the operation method, refer to the operating manual.

• The outdoor unit may not operate depending on the room temperature.

In this case, press the test run button on the remote control unit while

the air conditioner is running. (Point the transmitter section of the re-

mote control unit toward the air conditioner and press the test run but-

ton with the tip of a ball-point pen, etc.)

Transmitter section

Test run button

•

To end test operation, press the remote control unit START/STOP button.

(When the air conditioner is run by pressing the test run button, the

OPERATION indicator lamp and TIMER indicator lamp will simultane-

ously flash slowly.)

[Using the wired remote control]

• For the operation method, refer to the operating manual.

(1) Stop the air conditioner operation.

(2) Press the master control button and the fan control button simultane-

ously for 2 seconds or more to start the test run.

(3) Press the star t/stop button to stop the test run.

Test run display

Setting

Ceiling height

Filter sign

Cooler room temperature

correction

Heater room temperature

correction

Auto restart

Indoor room temperature

sensor switching function

Setting Value

Setting record

• Record any changes to the settings in the following table.

[Troubleshooting at the remote control LCD]

This is possible only on the wired remote control.

[SELF-DIAGNOSIS]

If an error occurs, the following display will be shown.

(“EE” will appear in the set room temperature display.)

Unit number

Error code

Ex. Self-diagnosis

Error code Error contents

Indoor signal error

Wired remote controller abnormal

Indoor room temperature sensor error

Indoor heat exchanger temperature sensor (middle)

error

Indoor heat exchanger temperature sensor (inlet)

error

Float switch operated

Outdoor discharge pipe temperature sensor error

Outdoor heat exchanger temperature sensor (outlet)

error

Outdoor temperature sensor error

Compressor temperature sensor error

2-way valve temperature sensor error

3-way valve temperature sensor error

Outdoor heat exchanger temperature sensor (middle)

error

Indoor manual auto switch abnormal

Power supply frequency detection error

IPM protection

CT error

Compressor location error

Outdoor fan error

Connected indoor unit abnormal

Outdoor unit computer communication error

Indoor fan abnormal

Discharge temperature error

Exessive high pressure protection on cooling

4-way valve abnormal

Pressure switch abnormal

Compressor temperature error

Active filter abnormal

PFC circuit error

01

13

26

27

00

02

04

28

09

0C

06

0A

15

1d

1E

29

20

2A

17

18

1A

1b

1F

1c

12

0F

24

2c

16

2b

19

25

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

1

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

2

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

3

OFF

OFF

OFF

OFF

ON

ON

ON

ON

OFF

OFF

OFF

OFF

ON

ON

ON

ON

4

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

ON

ON

ON

ON

ON

ON

ON

Unit number DIP SWITCH No.

9

SPECIAL INSTALLATION

METHODS

10

CUSTOMER GUIDANCE

Explain the following to the customer in accordance with the operating

manual:

(1) Star ting and stopping method, operation switching, temperature ad-

justment, timer, air flow switching, and other remote control unit op-

erations.

(2) Air filter removal and cleaning, and how to use the air louvers.

(3) Give the operating and installation manuals to the customer.

(4) If the signal code is changed, explain to the customer how it changed

(the system returns to signal code A when the batteries in the remote

control unit are replaced).

*(4) is applicable to using wireless remote control.

Indoor unit

Indoor signal error

Wired remote controller abnormal

Indoor room temperature sensor error

Indoor heat exchanger temperature

sensor (middle) error

Indoor heat exchanger temperature

sensor (inlet) error

Float switch operated

Outdoor discharge pipe temperature

sensor error

Outdoor heat exchanger temperature

sensor (outlet) error

Outdoor temperature sensor error

Compressor temperature sensor error

2-way valve temperature sensor error

3-way valve temperature sensor error

Outdoor heat exchanger temperature

sensor (middle) error

Indoor manual auto switch abnormal

Power supply frequency detection er-

ror

IPM protection

CT error

Compressor location error

Outdoor fan error

Connected indoor unit abnormal

Outdoor unit computer communication

error

Indoor fan abnormal

Discharge temperature error

Exessive high pressure protection on

cooling

4-way valve abnormal

Pressure switch abnormal

Compressor temperature error

Active filter abnormal

PFC circuit error

Error contents

OPERATION

lamp (Red)

(2 times)

(2 times)

(2 times)

(2 times)

(3 times)

(3 times)

(3 times)

(3 times)

(3 times)

(3 times)

(3 times)

(4 times)

(4 times)

(5 times)

(5 times)

(5 times)

(5 times)

(5 times)

(5 times)

(6 times)

(7 times)

(7 times)

(7 times)

(7 times)

(7 times)

(8 times)

(8 times)

TIMER lamp

(Green)

(8 times)

(2 times)

(3 times)

(4 times)

(6 times)

(2 times)

(3 times)

(4 times)

(8 times)

(2 times)

(4 times)

(2 times)

(3 times)

(5 times)

(6 times)

(7 times)

(8 times)

(2 or 3 times)

(2 times)

(3 times)

(4 times)

(5 times)

(6 times)

(2 or 3 times)

(4 times)

FILTER lamp

(Orange)

(2 times)

(3 times)

(4 times)

: 0.5s ON/0.5s OFF (Flash) : OFF

Troubleshooting

(Troubleshooting with the indoor display)

Troubleshooting at the display is possible either on the wired or wireless

remote control.

The OPERATION, TIMER and FILTER lamp operate as follows table ac-

cording to the error contents.

OPERATION lamp (Red)

TIMER lamp (Green)

FILTER lamp (Orange)

Loading...

Loading...