P

P

G

G

-

-

6

6

0

0

0

0

0

0

T

T

h

h

r

r

e

e

a

a

d

d

D

D

i

i

a

a

m

m

e

e

t

t

e

e

r

r

G

G

a

a

g

g

e

e

O

O

p

p

e

e

r

r

a

a

t

t

i

i

o

o

n

n

M

M

a

a

n

n

u

u

a

a

l

l

Inspecting Parts (continued)

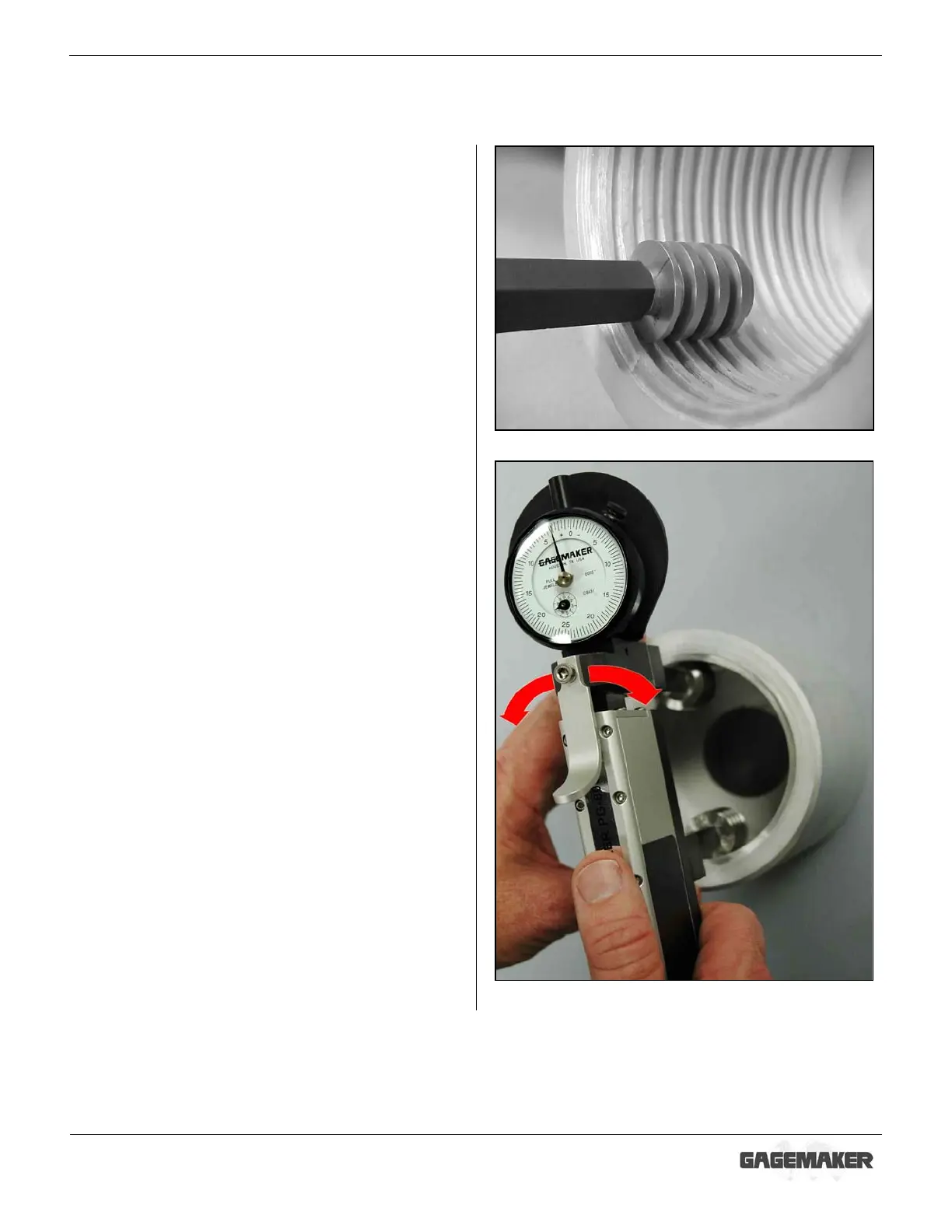

3. Ensure that the thread rolls on the PG-6000

fully engage with the threads in the part.

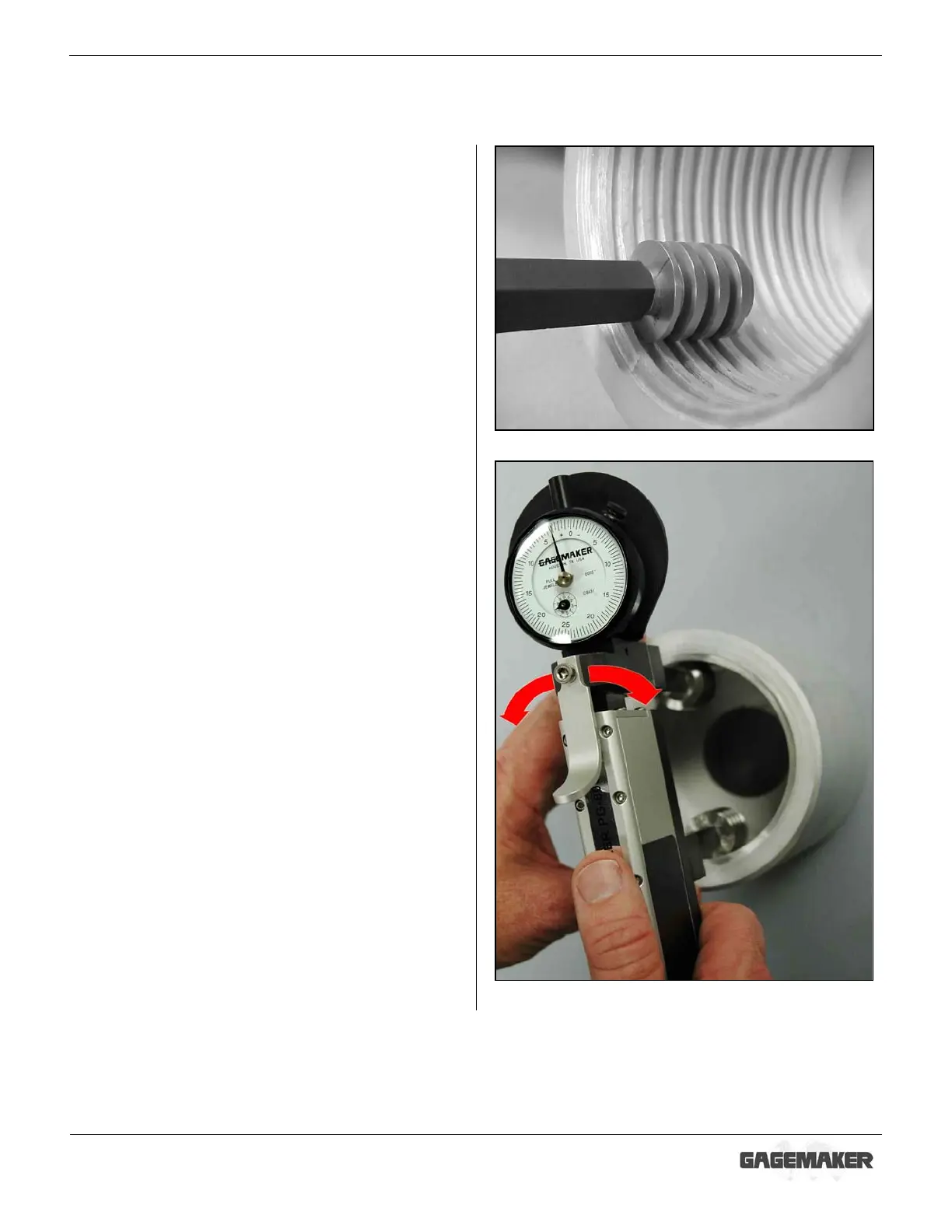

4. Sweep the PG-6000 gage back and forth to

locate the largest indicator reading on the part.

Use the gauging tolerances previously printed

from the Gagemaker screen in the Thread Disk

for Windows software to determine the

accuracy of the diameter.

5. Hold the gage steady at the largest reading and

rock the gage frame left and right to seat both

rolls and allow a maximum indicator reading.

Note: Be sure that the small revolution counter on

the indicator is pointing to the same number

as when the gage was zeroed. Refer to the

number previously recorded on the back of

the indicator.

Loading...

Loading...