11

GB

Fault Possible Cause Rectification

Abnormal Noises Screws / components loose v Tighten screws

Foreign bodies on the blade. v Remove foreign bodies.

Notch in the blade v Remove notches with

grindstone.

Blades are striking each other v Adjust cutting mechanism.

too hard.

Lawn is not cleanly cut Blade adjustment incorrect. v Adjust cutting mechanism.

Blade blunt. v Regrind or replace blade.

Grass too long (e.g. after a v Cut lawn shorter with a

relatively long absence). sickle.

The cutting gear of your lawn mower was optimally adjusted be-

fore leaving our company. If, after longer use, a clean cut of the

grass is no longer possible or the blade roller contacts the lower

blade, then the lower blade should be adjusted as follows:

1. Unhook upright and clean cylinder mower.

2. Check cylinder

9

and lower blade

0

for notches and remove

these with a grindstone if necessary.

3. Unscrew internal hexagon screws

A

with an internal hexagon

wrench (5 mm) anticlockwise until the cylinder

0

turns freely.

4. Push the feeler gauge supplied (thin strip of metal)

8

between one blade

9

on the cylinder and the lower blade

0

.

5. Tighten left internal hexagon screw

A

with an internal

hexagon wrench (5 mm) until the feeler gauge

8

is held

gently.

6. Continue turning the cylinder until the blade

9

, already

adjusted on the left side, is exactly above the lower blade

0

on the right side.

7. Tighten the right internal hexagon screw

A

with an internal

hexagon wrench (5 mm) until the feeler gauge

8

is held

gently.

8. Rotate cylinder

9

. If a banging noise is produced during this,

open up the internal hexagon screw

A

slightly on the side

affected.

When the cylinder and the lower blade can hardly be heard

touching each other, the cutting mechanism has been adjusted

correctly.

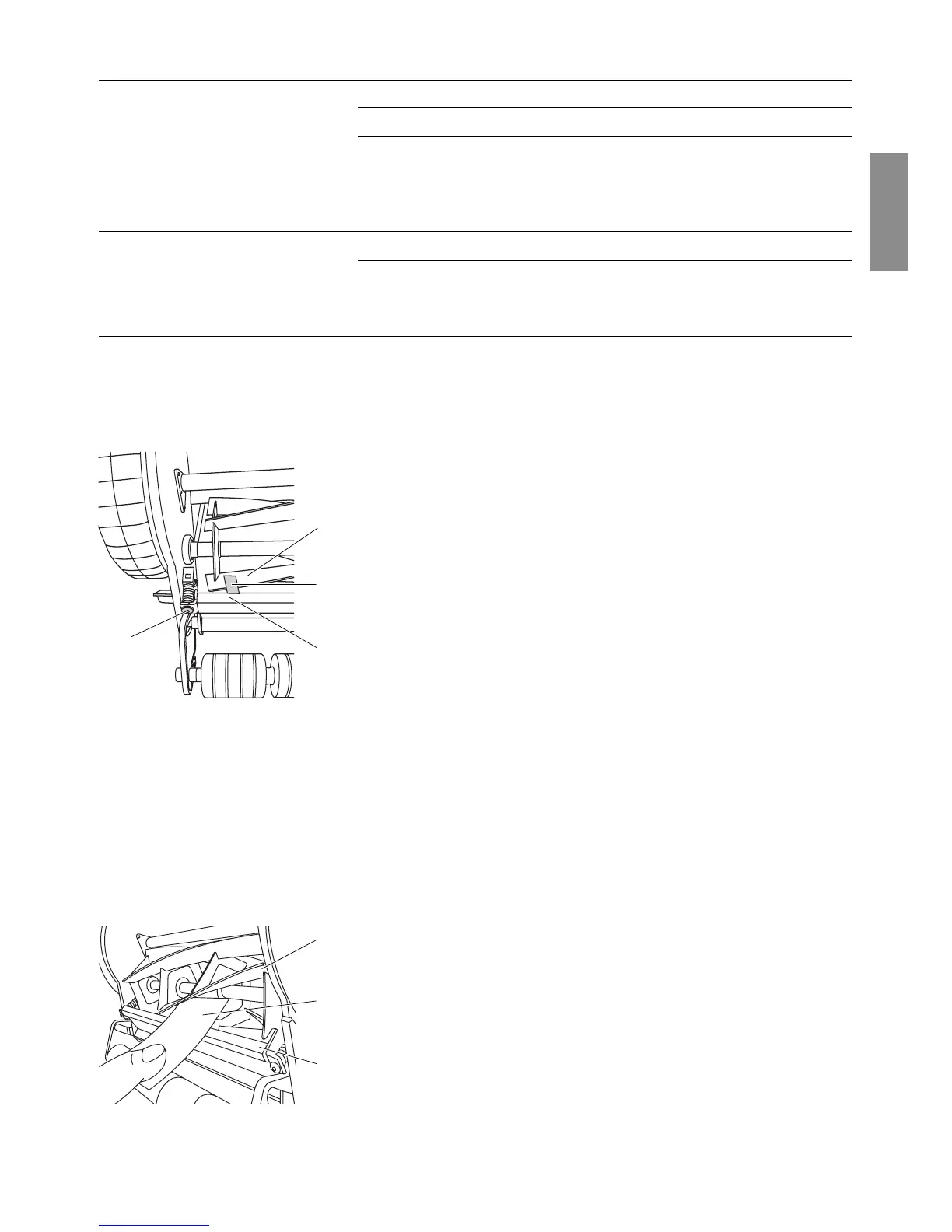

9. Cutting test:

Place a strip of paper

B

in such a way on the lower blade

0

that it points towards the spindle of the cylinder

9

.

10. Turn cylinder

9

carefully.

If the lower blade is set correctly

0

the paper will be cut off

as if with scissors.

11. Repeat the cutting test on the other blades

9

.

Adjusting the cutting

mechanism:

9

8

0

A

9

B

0

Loading...

Loading...