Speedrooter 91™

Cable Applications (Table 1)

Cable Size Pipe Size Typical Applications

3/4"

(Large Drum)

4" to 10" Large Drains, Long

Runs, Roots

5/8"

(Large Drum)

3" to 6" Stacks, Floor Drains,

Roots

1/2"

(Small Drum)

2" to 4" Stacks & Small Drains

(No Roots)

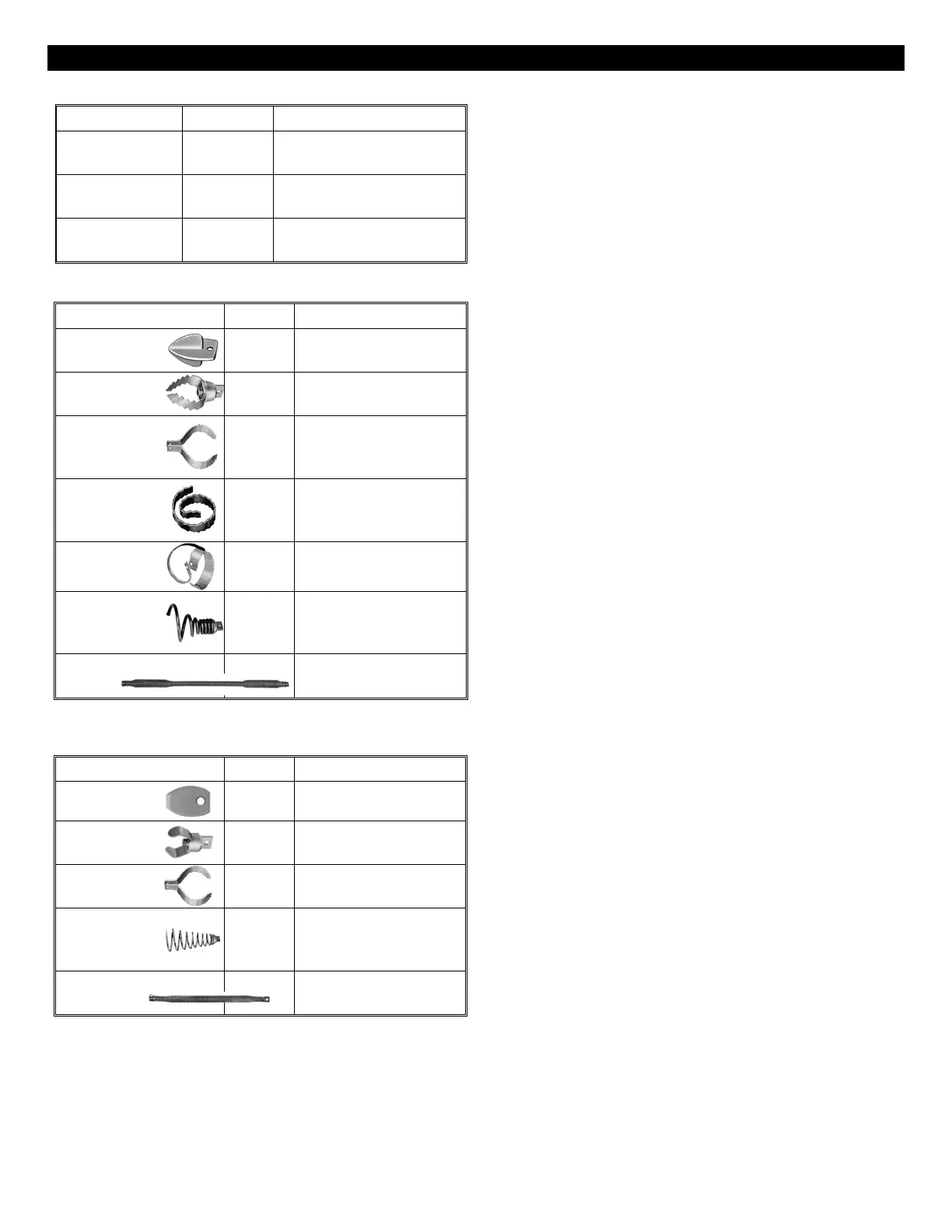

Cutter Applications (Table 2)

Cutter Cat. # Typical Applications

Spear

Head

SHD Starting Drill – gets

water flowing.

2" U-Cutter 2UC For Cutting and

Scraping.

3" & 4"

Side Cutter

Blades

3SCB

&

4SCB

For Cutting –

Scrapes walls of

pipe.

3" Heavy

Duty Saw

Blade

3HDB For Cutting Roots.

4" Rotary

Saw Blade

4RSB For Cutting Roots.

Large

Retrieving

Tool

RTR-2 For removing loose

objects or broken

cables.

33" Flexible

Leader

LE-2 Helps cable get

through tight traps.

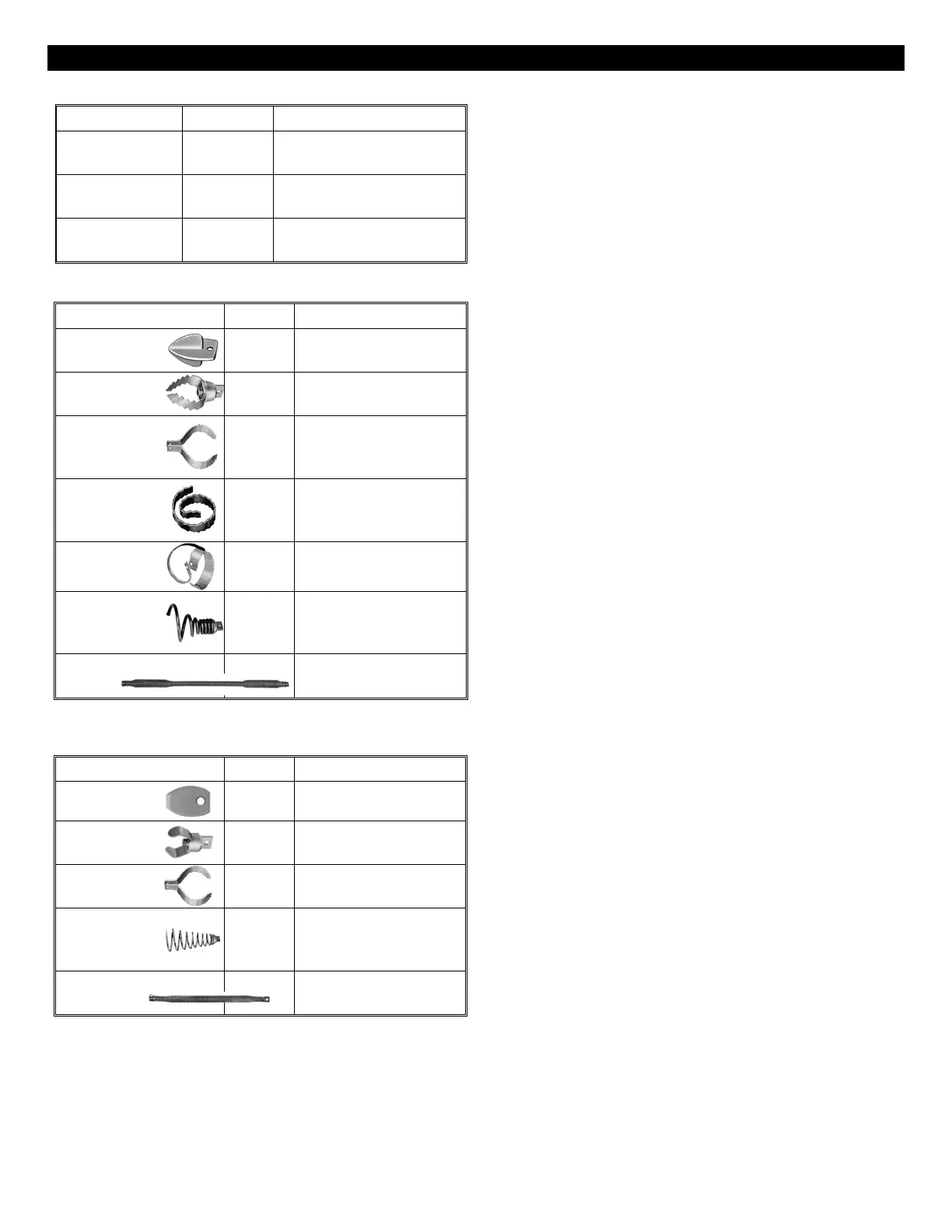

Additional cutters for use with 1/2" cable (included

in Combination Cutter Set sold with P-S91-A).

Cutter Cat. # Typical Applications

Arrow Head

AH Starting Drill – Gets

water flowing.

1-1/2”

U-Cutter

1-1/2UC For Cutting and

Scraping.

2” Side

Cutter Blade

2SCB For Cutting – Scrapes

walls of pipe.

Small

Retrieving

Tool

RTR-1 For removing loose

objects or broken

cables.

13" Flexible

Leader

LE-1 Helps cable get

through tight traps.

Note: There are no fixed rules for what cutter to use. If

one tool doesn't take care of a stoppage, simply try

another.

Operating Instructions

Set-up

1. Place machine within approximately two feet of

drain opening. Be sure the Speedrooter Guide

Tube (S91-GT) is in place. If you can't get the

machine this close to the drain opening, run the

cable through the optional Guide Tube

Extension (GTE) or a metal guide tube to

prevent cable whipping. On manual feed

machines, always keep a gloved hand on the

cable.

2. Position the air foot pedal for easy accessibility.

The machine is designed for one person

operation. Be sure you can quickly remove

your foot from the pedal in an emergency.

3. Lock the wheels by lifting the brake handle

located next to the left wheel and pressing it

into the clip.

4. Be sure the motor switch is in the

off

position.

5. Make sure the Power Cable Feed is set to

match the cable size you have selected. If

you’re using 3/4" or 5/8” cables, the feed should

be assembled with the raised side of the lower

two caps outward. If you are using 1/2" cables,

the feed should be assembled with the raised

side of the caps inward.

6. Select the proper cutting tool (See Cutter

Application Chart—Table 2). A good tool to

start with is the Spearhead or 2” U-Cutter. If

you are having difficulty getting around a P-

Trap or close bend, try the flexible leader. After

the line has been opened, follow with larger

blades, which scrape the inside edges of the

pipe, assuring a real cleaning job.

7. Insert the cutter into the female connector at the

end of the cable and tighten the connecting

screw and lock washer

firmly

in place.

Hint: Some users “mix” their cutters on certain jobs.

For instance, they use one 2” Side Cutter

Blade with one 4” Side Cutter Blade. This

combination is especially good when working

through 4” P-Traps.

5

Loading...

Loading...