Do not interfere with nozzles, freeze heads or valves, including cylinder valves.

Work only in a well ventilated area

. Carbon dioxide is non-toxic and non-

flammable but it is heavier than air and can therefore collect at ground level and

displace the air if ventilation is inadequate, giving rise to the danger of suffocation.

Wear eye protection or goggles.

Wear gloves.

Do not work with an open flame within 2 ft. (50 cm) of the freezing point.

Never hit a chilled freeze head with a hammer or other tool. A sharp blow will cause

it to fracture.

Keep other people, particularly children, well away. Dry ice causes burns if it comes

into contact with the skin. Once work is complete, any remaining dry ice in the

freeze heads must be carefully disposed of or placed in a covered refuse container.

Observe the safety instructions provided by the carbon dioxide supply company.

How the Cold-Shot Works

The Cold-Shot can be used to freeze all types of liquids, even at high pressure,

inside steel, copper, cast iron, lead, aluminum and plastic pipe in sizes ranging from

1/8" to 2" (10-60 mm).

The Cold-Shot uses commercially available carbon dioxide (CO²). You can

purchase or rent cylinders through your local welding supply house. Though any size

cylinder can be used, it is recommended that users purchase the largest cylinder size

possible.

Note: the CO² tank must have a dip tube.

The dip tube allows liquid rather

than gas to flow through the spiral hoses were it will expand to form Dry-ice inside the

freeze heads.

The ice pack which forms in the pipe is capable of withstanding a pressure of

approximately 7000 psi (500 bar). As the liquid freezes, a layer of frost will develop on

the surface of the pipe.

Preparation

1. Remove the seal from the carbon dioxide cylinder.

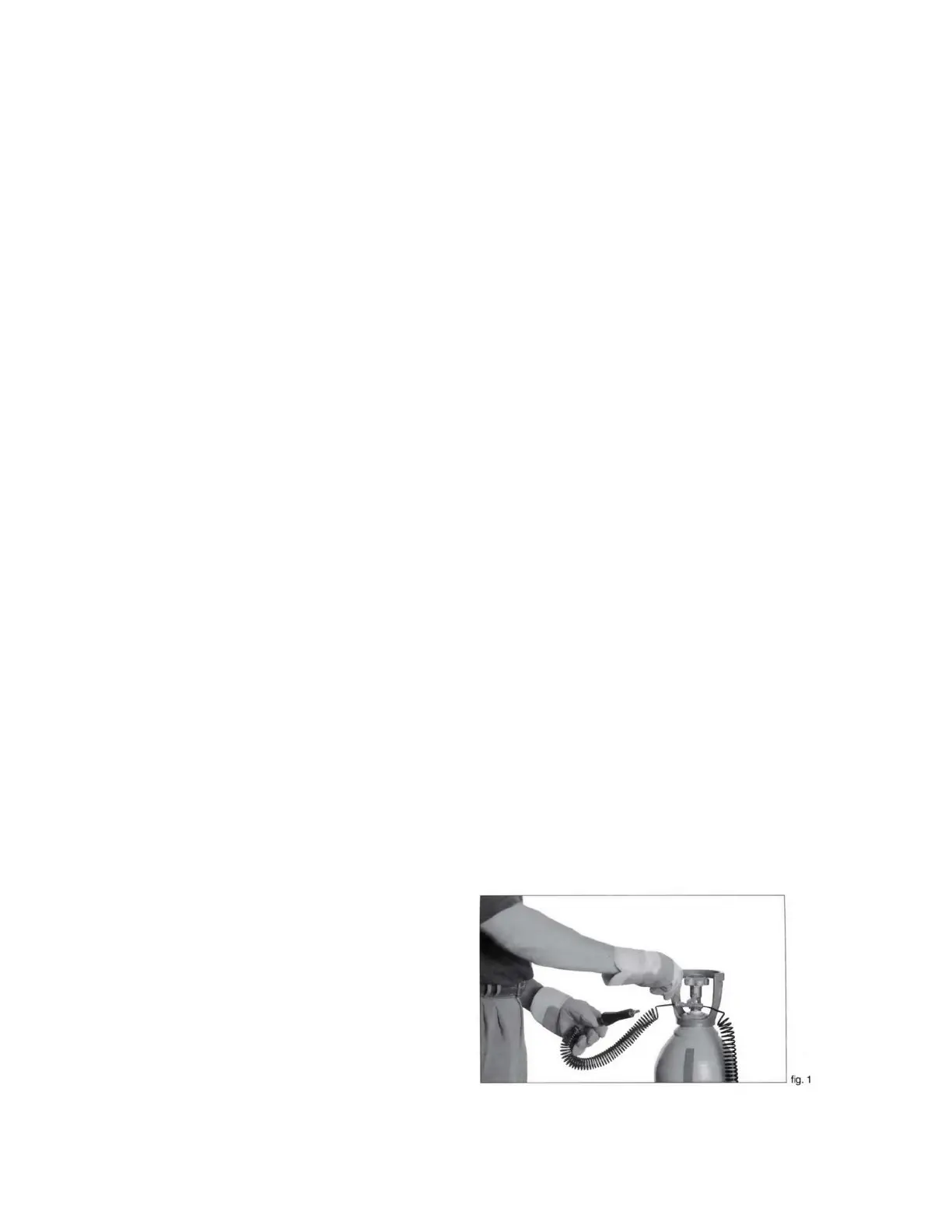

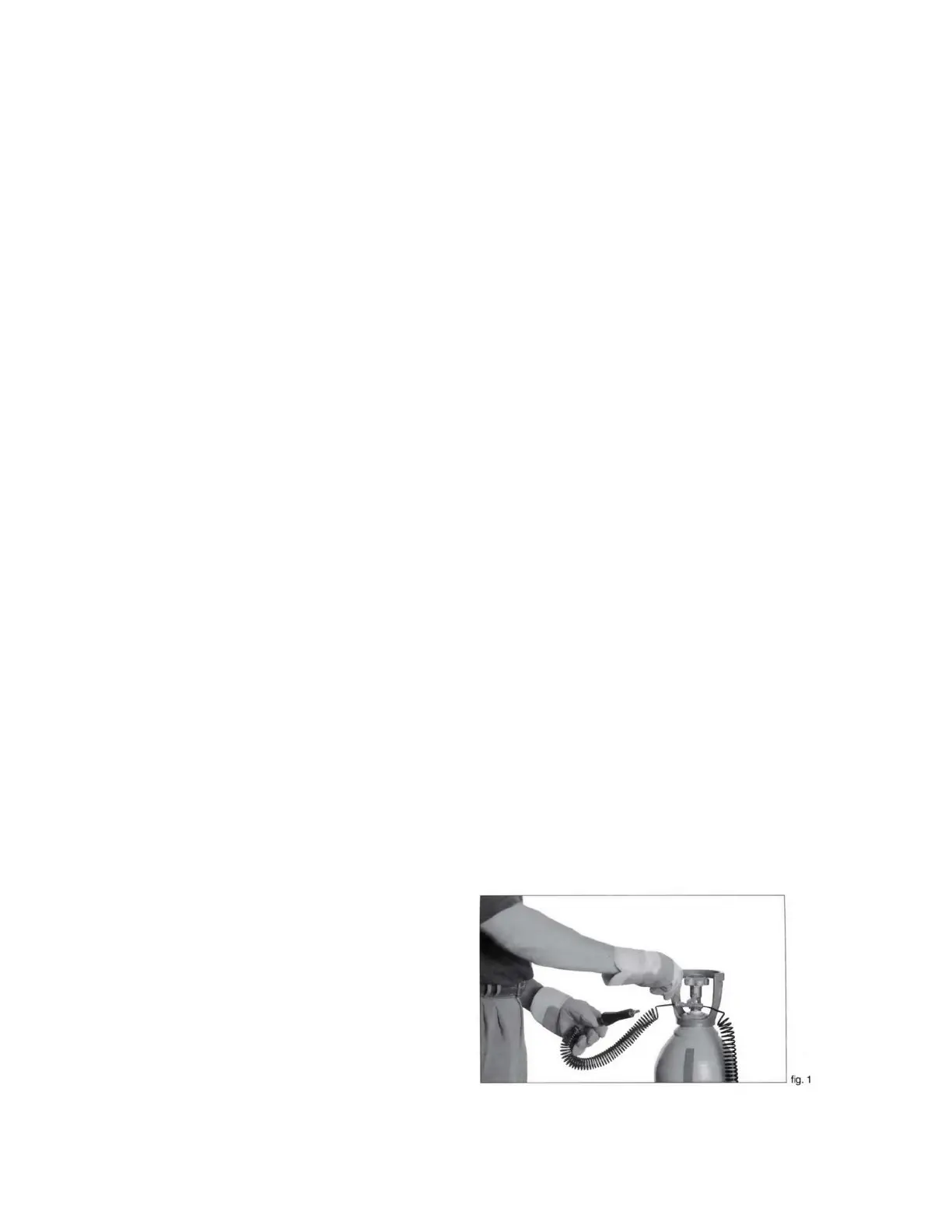

2. Screw connector with T-distributor on to cylinder (right-hand thread).

3. Screw spiral hoses on to the

T-distributor. (Fig. 1)

4. Choose freeze heads which

correspond to the size of the pipe to

be frozen.

2

Loading...

Loading...