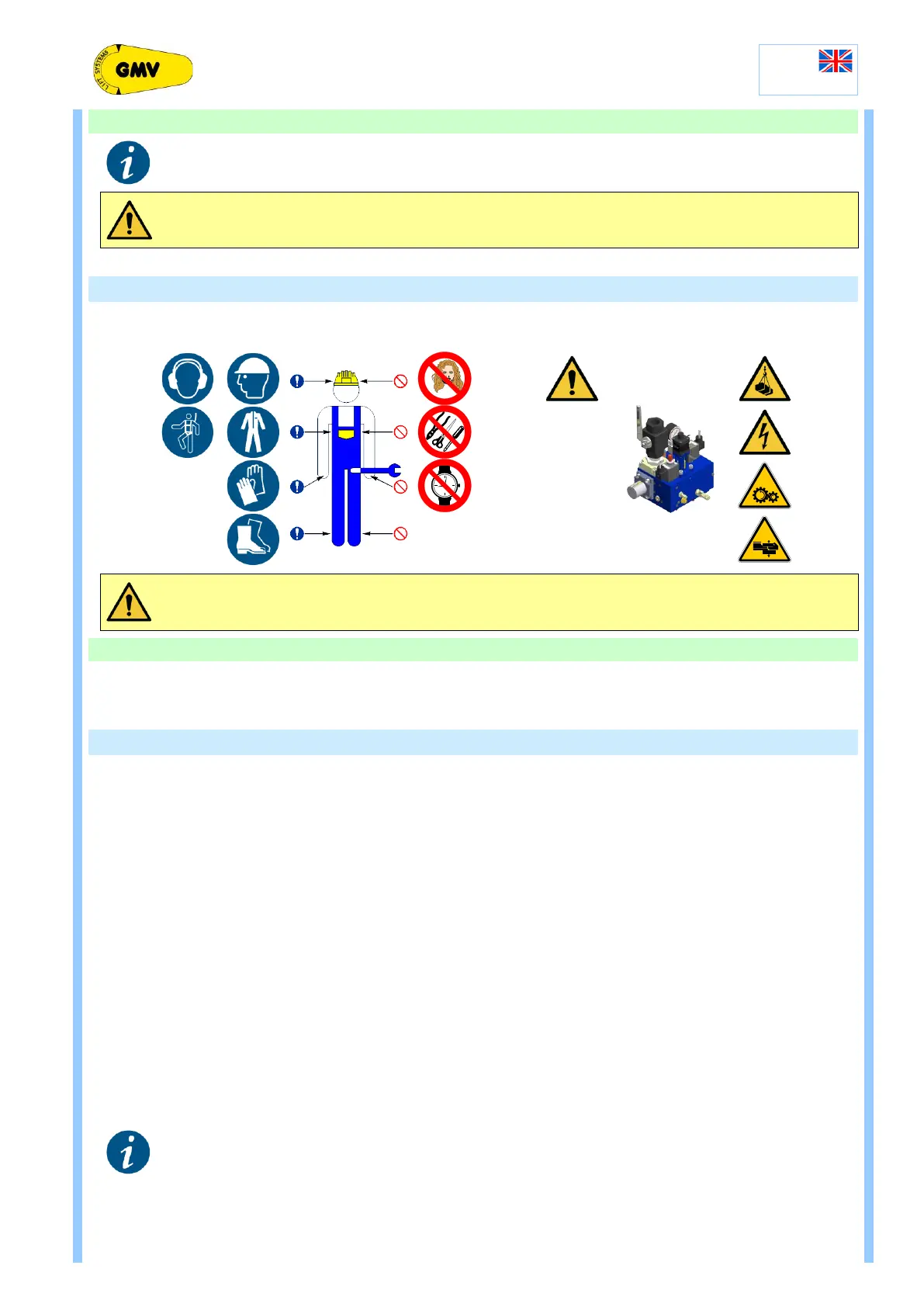

WARNING

A warning that the described operation could cause damage to the system or physical injury, even

serious, if the safety rules are not observed.

WARNING

Before starting any kind of installation operation.

ALWAYS check that all the safety devices, mechanical or electrical, are active and working properly.

No special tools are required unless expressly provided by component manufacturers supplied by third

parties. In this case, the related features and operating instructions are indicated in the manuals supplied

with them.

This manual is intended for a competent person in charge of installation and/or maintenance, that is, whois

in charge, adequately trained, (see EN ISO 9000 series), qualified for knowledge and practical experience,

provided with the necessary instructions and supported in the maintenance organization to allow the

required installation and/or maintenance operations to be carried out safely.

Valves must be kept in good operating condition in accordance with regulations.

To achieve this result, regular maintenance must be carried out that guarantees, in particular, the safety of

the system.

It is recommended to perfectly clean all hydraulic components, including pipes and fittings, before mounting

them, especially if disassembled for inspection or repair, as impurities and dirt inside them cause

malfunctions and wear.

Any fluid leaking from the circuit during repair operations must not be dispersed in the environment, but must

be promptly collected and disposed of according to current regulations.

The safety of an installation must consider its ability to be maintained without causing injury or damage to

human health.

Regular maintenance must be carried out to ensure reliability.

Accesses and surrounding areas must be maintained in good operating condition.

The competence of the maintenance person within the maintenance organization must be continuously

updated.

NOTE

The system owner must ensure that the maintenance team qualification complies with the applicable

regulations in the country where the system is installed. Should there be no specific regulations,

qualification may be guaranteed by a certified quality system according to EN IS0 9001 standards,

integrated, if required, to consider the specific features of the system in question.

Loading...

Loading...