6

Electrical Connections

HIGH VOLTAGE!

Disconnect ALL power before servicing.

Multiple power sources may be present.

Failure to do so may cause property damage,

personal injury or death due to electric shock.

Wiring must conform with NEC or CEC and all

local codes. Undersized wires could cause

poor equipment performance, equipment damage

or fire.

WARNING

To avoid the risk of fire or equipment damage, use

copper conductors.

WARNING

NOTICE

Units with reciprocating compressors and non-bleed TXV’s

require a Hard Start Kit.

This unit is designed for three phase operation. DO NOT

OPERATE ON A SINGLE PHASE POWER SUPPLY. Mea-

sure the power supply to the unit. The supply voltage must

be in agreement with the unit rating plate power require-

ments and within the range listed below:

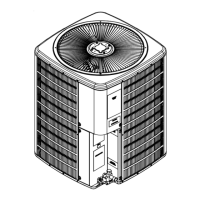

MODEL

MINIMUM SUPPLY

VOLTAGE

MAXIMUM SUPPLY

VOLTAGE

GSH100903 197 253

GSH100904 414 506

GSH101203 197 253

GSH101204 414 506

The condensing unit rating plate lists pertinent electrical data

necessary for proper electrical service and overcurrent pro-

tection. Wires should be sized to limit voltage drop to 2%

(max.) from the main breaker or fuse panel to the condens-

ing unit. Consult the NEC, CEC, and all local codes to de-

termine the correct wire gauge and length. The wire size

must be sufficient to carry the Minimum Circuit Ampacity

(MCA) listed on the serial plate and the following table:

MODEL MCA

GSH100903 37.6

GSH100904 18.7

GSH101203 43.2

GSH101204 22.1

The supply voltage can be unbalanced (phase to phase)

within 2%. The following formula can be used to determine

the percentage of voltage unbalance for your unit.

Percentage

Voltage

Unbalance

=

100 x

Max. Voltage Deviation Form

Average Voltage

Average Voltage

Example:

L1-L2 = 220V

L2-L3 = 216V

Average Voltage = (220 + 216 + 213)/3

=649/3

Maximum Deviation from Average = 220 - 216 = 4

% Voltage Unbalance = 100 x (4/216)

= 400/216

10 15 20 25 30 35 40 45

14 75 50 37 NR NR NR NR NR

12 118 79 59 47 NR NR NR NR

10 188 125 95 75 63 54 NR NR

8 301 201 150 120 100 86 75 68

6 471 314 235 188 157 134 118 110

*Based on NEC 1996

MAXIMUM ALLOWABLE LENGTH IN FEET

TO LIMIT VOLTAGE DROP TO 2%

Minimum Circuit Ampacity (MCA)

Wire Size

(AWG)

Example:

A GSH100903 is to be installed. The distance from the

building to the unit is 75’. Calculate the minimum wire size

assuming no more than 2% voltage drop.

MCA for GSH100903 = 43.3 (from S& R plate and table).

Applying previous table wire sizes less than #8 AWG

cannot be used for circuits which have a rating of 45A.

The #8 wire is not suitable since the maximum length for

a 45A circuit is 68’.

Solution: Use a #6 AWG wire suitable up to 110’.

NOTE: It is the contractors’s responsibility to follow the

NEC(USA) or CEC (Canada) when sizing the service wire

for this unit.

Local codes often require a disconnect switch located near

the unit; do not install the switch on the unit. Refer to the

installation instructions supplied with the indoor furnace/air

handler for specific wiring connections and indoor unit con-

figuration. Likewise, consult the instructions packaged with

the thermostat for mounting and location information.

Overcurrent Protection

The following overcurrent protection devices are approved

for use.

• Time delay fuses

• HACR type circuit breakers

These devices have sufficient time delay to permit the motor-

compressor to start and accelerate its load.

Loading...

Loading...