ENGINE

GOVERNING

S

YSTEM

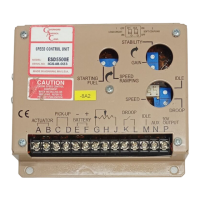

ESD5500E Series

Speed Control Unit

Governors America Corp., 720 Silver Street Agawam, MA 01001

phone: 413.786.5600 fax: 413.789.7736

www.governors-america.com

info@governors-america.com

1

O

MERICA

ORP.

C

A

®

ISO 9001

CERTIFIED

INSTALLATION

The speed control unit is rugged enough to be placed in

a control cabinet or engine mounted enclosure with other

dedicated control equipment. If water, mist, or condensation

may come in contact with the controller, it should be mount-

ed vertically. This will allow the fluid to drain away from the

speed control unit. Extreme heat should be avoided.

WIRING

Basic electrical connections are illustrated in Diagram 1. Ac-

tuator and battery connections to Terminals A, B, E, and F

should be #16 AWG (1.3 mm sq.) or larger. Long cables re-

quire an increased wire size to minimize voltage drops.

The battery positive (+) input, Terminal F, should be fused for

15 amps as illustrated.

Magnetic speed sensor wires connected to Terminals C and

D MUST BE TWISTED AND/OR SHIELDED for their en-

tire length. The speed sensor cable shield should ideally

be connected as shown in Diagram 1. The shield should be

insulated to insure no other part of the shield comes in con-

tact with engine ground, otherwise stray speed signals may

be introduced into the speed control unit. With the engine

stopped, adjust the gap between the magnetic speed sensor

and the ring gear teeth. The gap should not be any smaller

than 0.020 in. (0.45 mm). Usually, backing out the speed

sensor 3/4 turn after touching the ring gear teeth will achieve

a satisfactory air gap. The magnetic speed sensor voltage

should be at least 1 VAC RMS during cranking.

ADJUSTMENTS

Before Starting Engine

Check to insure the GAIN and STABILITY adjustments, and

if applied, the external SPEED TRIM CONTROL are set to

mid position.

Preset the ESD5500E as follows:

STARTING FUEL FULL CW(Maximum Fuel)

SPEED RAMPING FULL CCW(Fastest)

Start Engine

The speed control unit governed speed setting is factory set

at approximately engine idle speed. (1000 Hz., Speed sen-

sor signal)

Crank the engine with DC power applied to the governor sys-

tem. The actuator will energize to the maximum fuel position

until the engine starts. The governor system should control

the engine at a low idle speed. If the engine is unstable after

starting, turn the GAIN and STABILITY adjustments counter-

clockwise until the engine is stable.

Governor Speed Setting

The governed speed set point is increased by clockwise

rotation of the SPEED adjustment control. Remote speed

adjustment can be obtained with an optional 5K Speed Trim

Control. (See Diagram 1.)

Governor Performance

Once the engine is at operating speed and at no load, the

following governor performance adjustment can be made.

A. Rotate the GAIN adjustment clockwise until instability

develops. Gradually move the adjustment counterclock-

wise until stability returns. Move the adjustment one

division further counterclockwise to insure stable perfor-

mance (270° pot).

B. Rotate the STABILITY adjustment clockwise until insta-

bility develops. Gradually move the adjustment counter-

clockwise until stability returns. Move the adjustment one

division further to insure stable performance (270° pot).

C. Gain and stability adjustments may require minor chang-

es after engine load is applied. Normally, adjustments

made at no load achieve satisfactory performance. A

strip chart recorder can be used to further optimize the

adjustments.

If instability cannot be corrected or further performance

improvements are required, refer below to the SYSTEM

TROUBLESHOOTING section.

Starting Fuel Adjustment

The engine’s exhaust smoke at start-up can be minimized by

completing the following adjustments:

1. Place the engine in idle by connecting Terminals M & G.

2. Adjust the IDLE speed for as low a speed setting as the

application allows.

3. Adjust the STARTING FUEL CCW until the engine speed

begins to fall. Increase the STARTING FUEL slightly so

⚠WARNING

An overspeed shutdown device, independent of

the governor system, should be provided to pre-

vent loss of engine control, which may cause per-

sonal injury or equipment damage. Do not rely

exclusively on the governor system electric ac-

tuator to prevent overspeed. A secondary shutoff

device, such as a fuel solenoid, must be used.

Loading...

Loading...