3308244

Installation

WARNING

INJECTION HAZARD

Follow the Pressure Relief Procedure

when you stop spraying and before

cleaning, checking, servicing, or trans-

porting equipment. Read warnings, page 2.

Pressure Relief Procedure

1. Engage the gun trigger safety.

2. Turn off the power to the pump.

3. Disengage the trigger safety. Hold a metal part of

the gun firmly to the side of a grounded metal pail,

and trigger the gun to relieve the pressure.

4. Engage the gun trigger safety.

5. Open the pressure drain valve. Leave the valve

open until you are ready to spray again.

If you suspect that the spray tip or hose is completely

clogged, or that pressure has not been fully relieved

after following the steps above, VERY SLOWLY

loosen the tip guard retaining nut or hose end coupling

to relieve the pressure gradually, then loosen com-

pletely. Now clear the tip or hose.

Installation

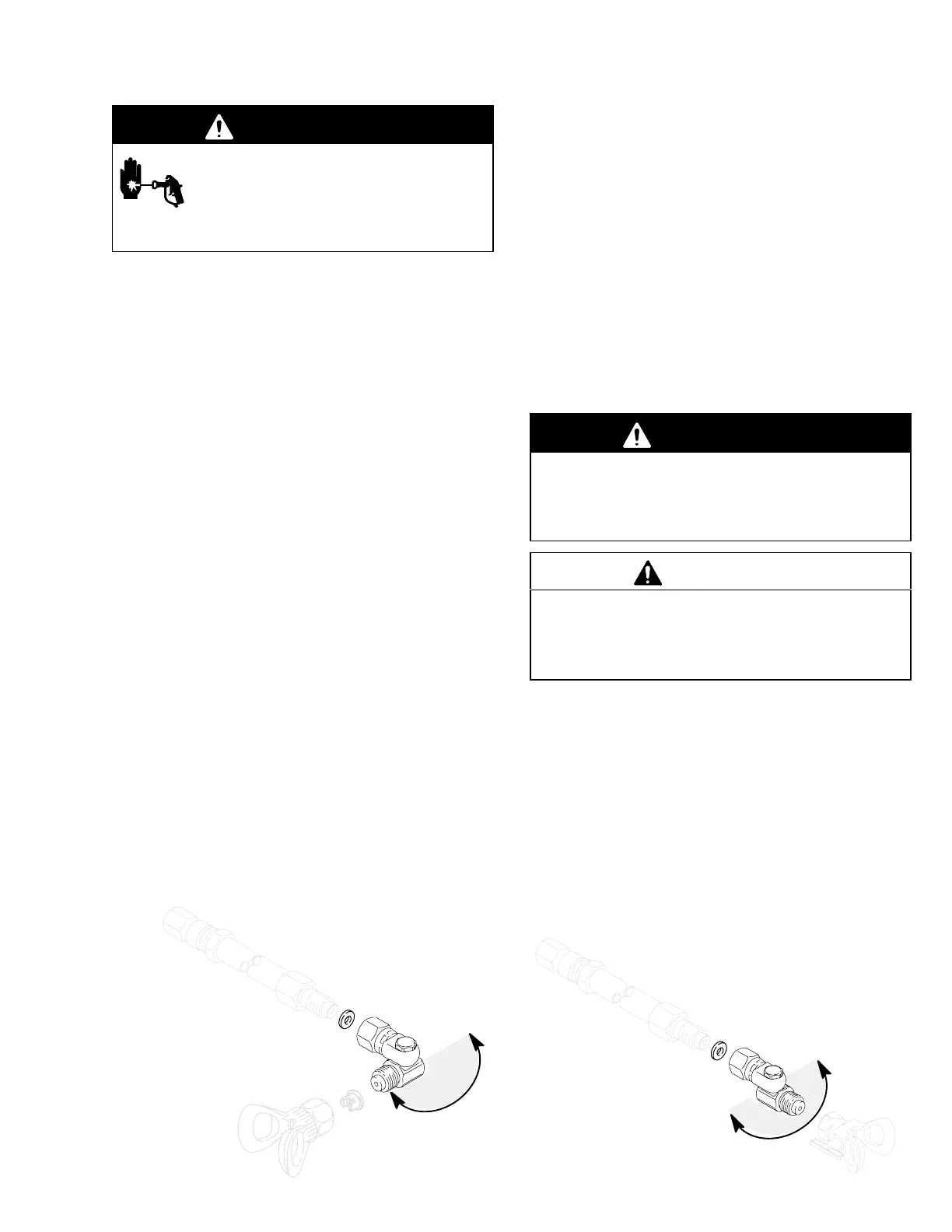

1. Install the adapter on the gun as shown, but do not

install a spray tip yet. Be sure the gaskets are in

place.

2. Flush and prime the spray system.

3. Relieve the pressure.

4. Install the spray tip.

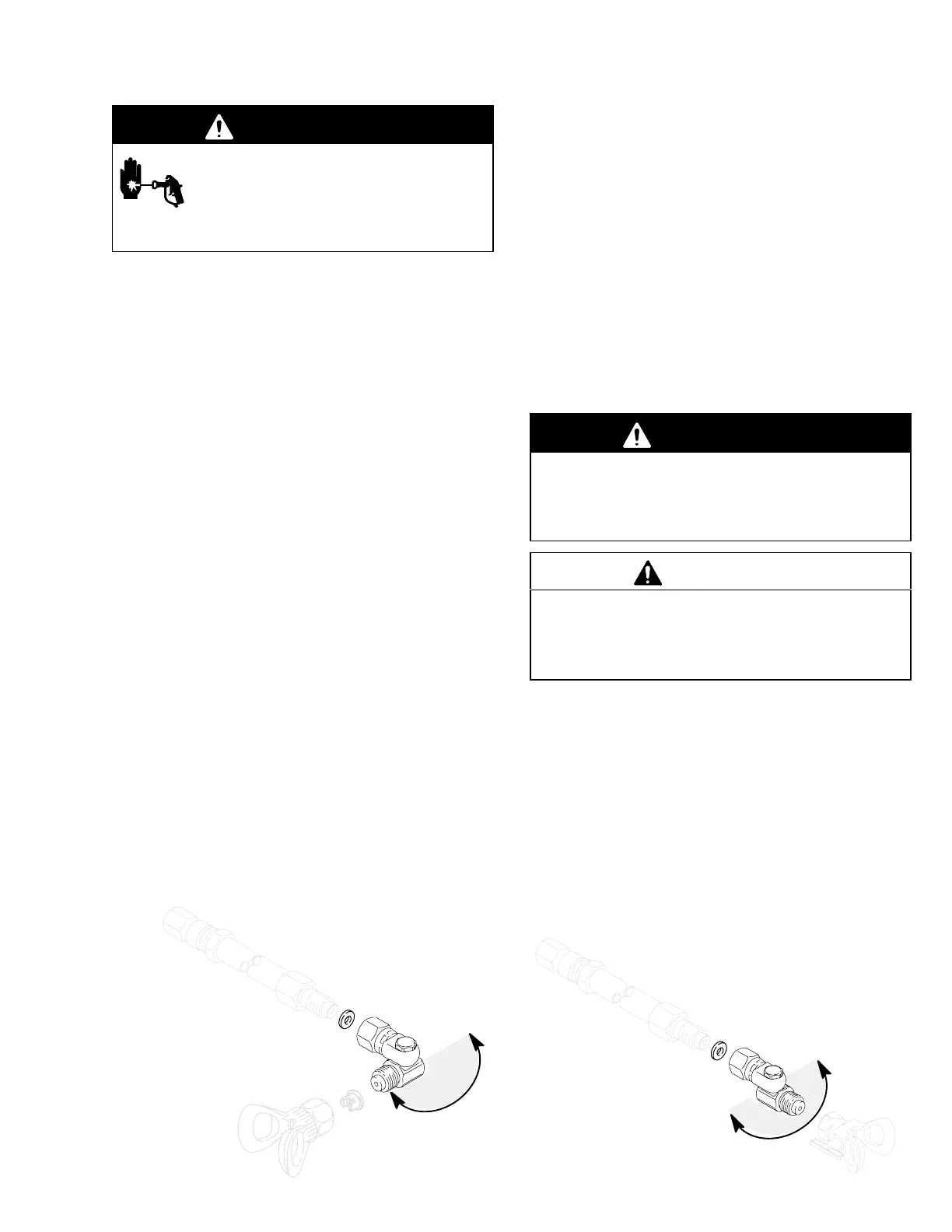

5. Turn the adapter to any desired position within

180. Do not use any tools.

6. Refer to your separate gun instruction manual for

operating and tip cleaning instructions.

7. This adapter is not repairable.

WARNING

To reduce the risk of serious bodily injury from fluid

injection or splashing in the eyes or on the skin,

stop using the nozzle immediately if it starts to leak

or cannot be turned easily.

CAUTION

To avoid damage to the o–ring in the swivel:

Relieve fluid pressure before rotating the swivel.

Do not soak the entire swivel in solvent.

Technical Data

Maximum Working Pressure 3600 psi. . . . . . . . . . . . . .

(24.8 MPa, 248 bar)

Fluid Inlet/Outlet Size 7/8–14 UNC. . . . . . . . . . . . . . . . .

Wetted Parts Aluminum, Delrin, PTFE,. . . . . . . . . . . .

Nylon, Stainless Steel

Delrin is a registered trademark of the DuPont Co.

180

Standard Flat Tip Guard

RAC DripLess Tip Guard

180

Loading...

Loading...