82

CHECKING, CLEANING OR REPLACING THE AIR FILTER

ATTENTION: Operating the machine without a functional air lter may cause severe engine

damage and will void any warranty. A dirty or oil saturated air lter will restrict air ow, which can

be mistaken as fuel system problems. Check the condition of the air lter before adjusting engine

idle speed, where applicable. If the air lter is damaged (torn, broken, disintegrating), replace it.

The air lter is used to prevent dirt and other particles from possibly entering the engine and causing internal damage

to it. The air lter requires regular maintenance as per the maintenance schedule.

AIR FILTER INSPECTION AND CLEANING

Inspect the air lter for dirtiness and debris, damage, etc. Clean or replace the lter element as necessary.

To clean air lters:

• For foam lters, wash the lter in warm water and mild detergent, then rinse and allow to dry.

• For paper lters, use compressed air to blow particles from it, if possible. The air should be blown from the engine

side of the lter. Tapping the lter element against a hard surface and brushing the pleats using a soft brush may

also help remove debris from the lter.

• For foam lters, place a few drops of clean engine oil on the lter then squeeze it a few times to spread the oil

through the lter material and remove any excess oil.

• It is recommended to clean the air lter cover and air intake assembly of any dirt, cuttings, etc.

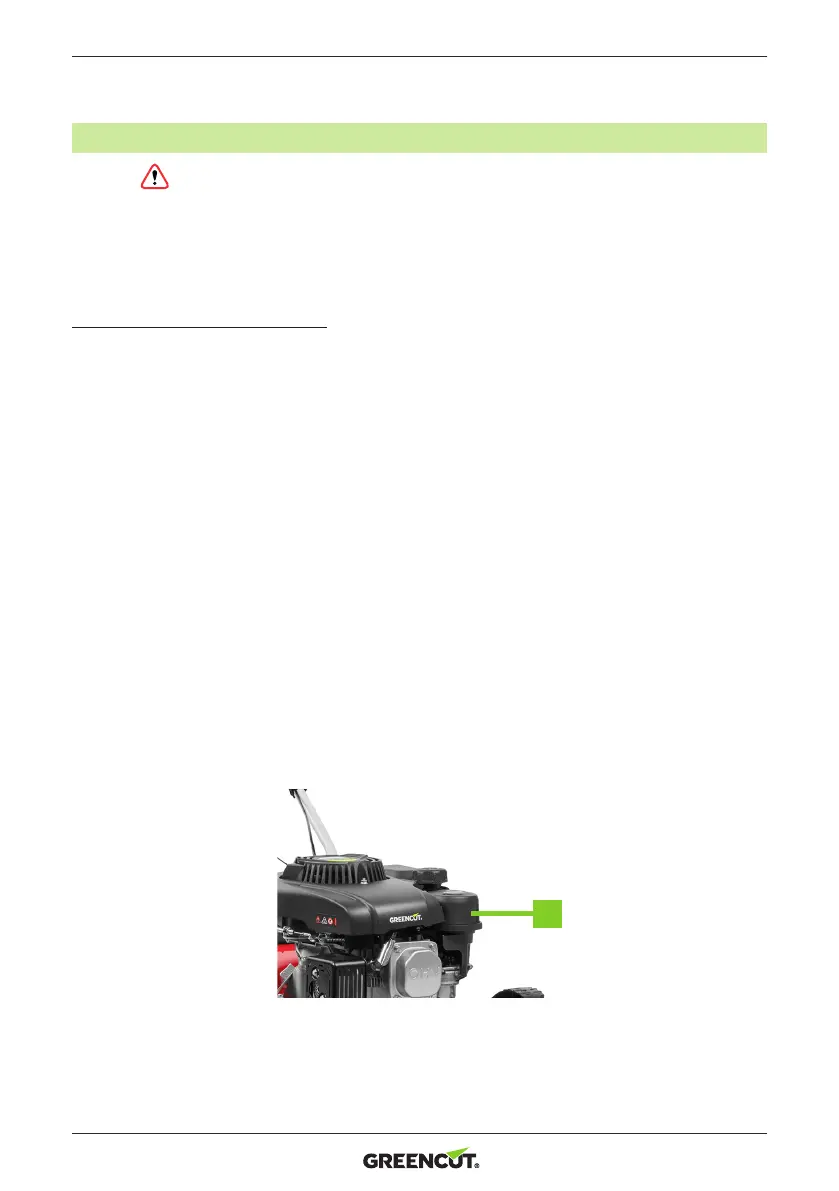

To remove the air lter:

1. Carefully remove the air lter cover by pressing the upper clips.

2. Remove the lter element (D).

To install the air lter:

1. Insert the air lter element, and ensure it is correctly positioned in relation to the air intake assembly as it will

seat and seal properly in one position only.

2. Re-install the lter cover, ensuring it is tted properly against the engine and secure it with the clips.

8

Loading...

Loading...