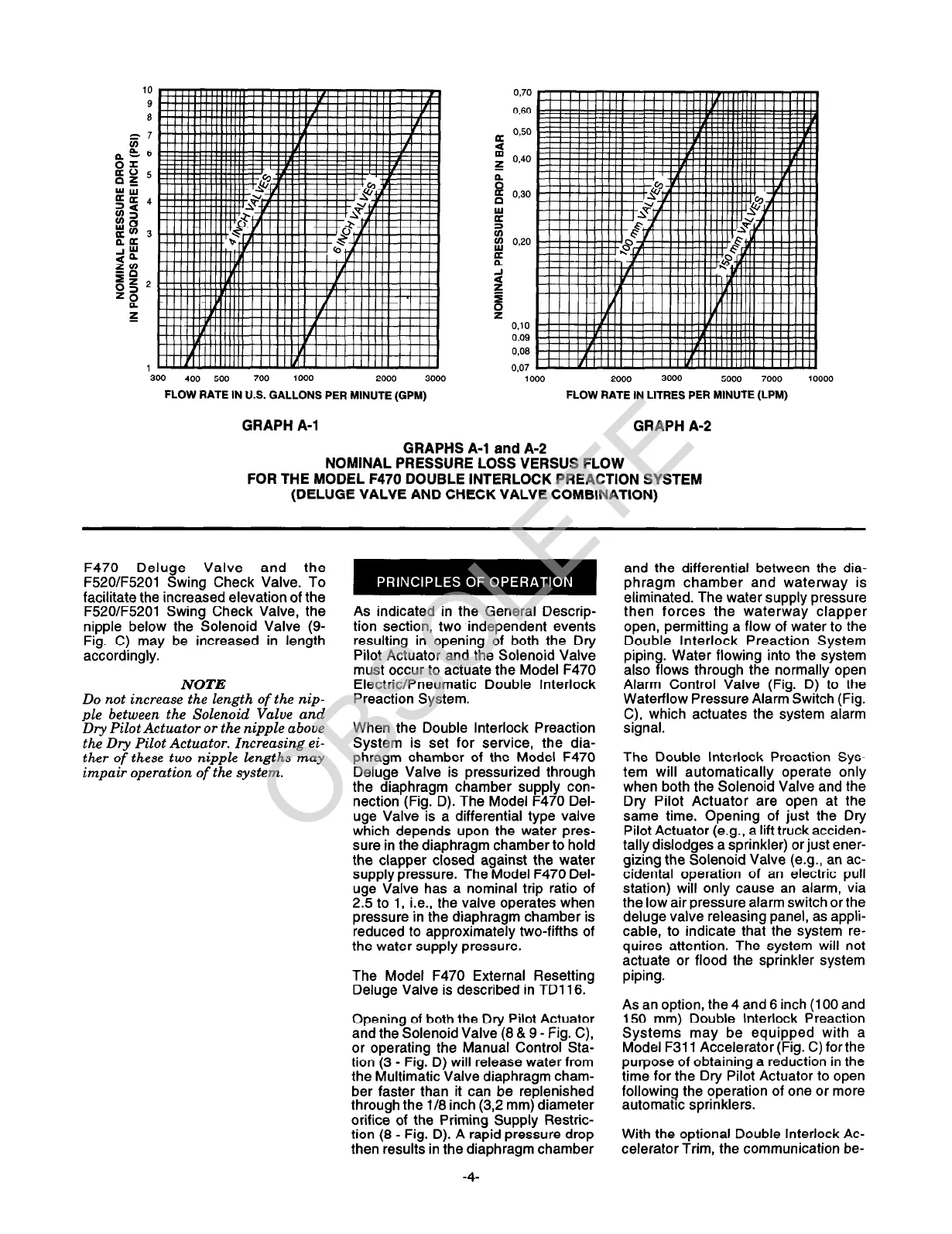

300 400 500 700 1000

2000 3000

FLOW RATE IN U.S. GALLONS PER MINUTE (GPM)

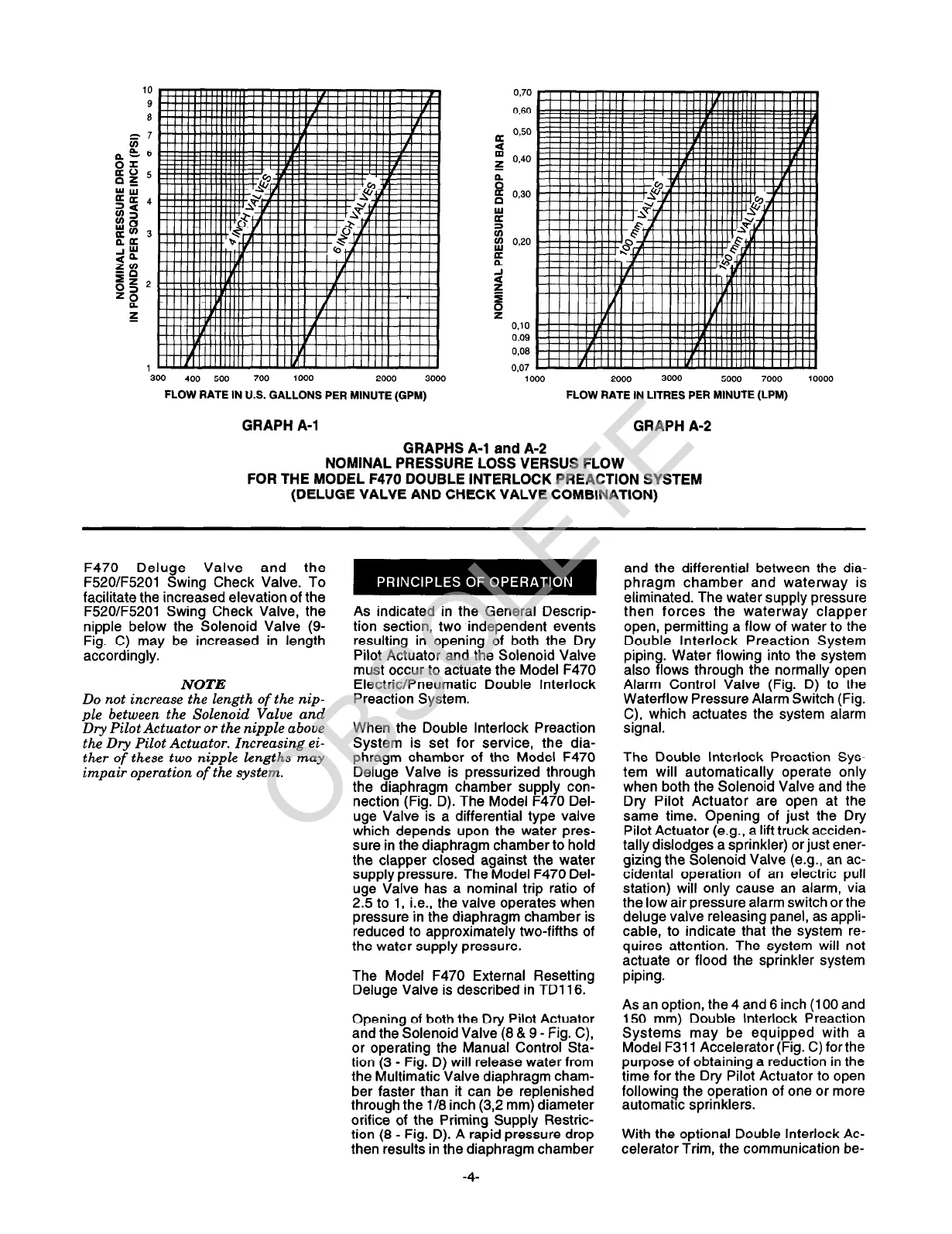

100 2000 3000 5000

7000 10000

FLOW RATE IN LITRES PER MINUTE (LPM)

GRAPH A-l

GRAPHS A-l and A-2

GRAPH A-2

NOMINAL PRESSURE LOSS VERSUS FLOW

FOR THE MODEL F470 DOUBLE INTERLOCK PREACTION SYSTEM

(DELUGE VALVE AND CHECK VALVE COMBINATION)

F470 Deluge Valve and the

F52OIF5201 Swing Check Valve. To

facilitate the increased elevation of the

F52O/F5201 Swing Check Valve, the

nipple below the Solenoid Valve (9-

Fig. C) may be increased in length

accordingly.

NOTE

Do not increase the length of the nip-

ple between the Solenoid Valve and

Dry Pilot Actuator or the nipple above

the Dry Pilot Actuator. Increasing ei-

ther of these two nipple lengths may

impair operation of the system.

As indicated in the General Descrip-

tion section, two independent events

resulting in opening of both the Dry

Pilot Actuator and the Solenoid Valve

must occur to actuate the Model F470

Electric/Pneumatic Double Interlock

Preaction System.

When the Double Interlock Preaction

System is set for service, the dia-

phragm chamber of the Model F470

Deluge Valve is pressurized through

the diaphragm chamber supply con-

nection (Fig. D). The Model F470 Del-

uge Valve is a differential type valve

which depends upon the water pres-

sure in the diaphragm chamber to hold

the clapper closed against the water

supply pressure. The Model F470 Del-

uge Valve has a nominal trip ratio of

2.5 to 1, i.e., the valve operates when

pressure in the diaphragm chamber is

reduced to approximately two-fifths of

the water supply pressure.

The Model F470 External Resetting

Deluge Valve is described in TD116.

Opening of both the Dry Pilot Actuator

and the Solenoid Valve (8 & 9 - Fig. C),

or operating the Manual Control Sta-

tion (3 - Fig. D) will release water from

the Multimatic Valve diaphragm cham-

ber faster than it can be replenished

through the l/8 inch (3,2 mm) diameter

orifice of the Priming Supply Restric-

tion (8 - Fig. D). A rapid pressure drop

then results in the diaphragm chamber

-4-

and the differential between the dia-

phragm chamber and waterway is

eliminated. The water supply pressure

then forces the waterway clapper

open, permitting a flow of water to the

Double Interlock Preaction System

piping. Water flowing into the system

also flows through the normally open

Alarm Control Valve (Fig. D) to the

Waterflow Pressure Alarm Switch (Fig.

C), which actuates the system alarm

signal.

The Double Interlock Preaction Sys-

tem will automatically operate only

when both the Solenoid Valve and the

Dry Pilot Actuator are open at the

same time. Opening of just the Dry

Pilot Actuator (e.g., a lift truck acciden-

tally dislodges a sprinkler) or just ener-

gizing the Solenoid Valve (e.g., an ac-

cidental operation of an electric pull

station) will only cause an alarm, via

the low air pressure alarm switch orthe

deluge valve releasing panel, as appli-

cable, to indicate that the system re-

quires attention. The system will not

actuate or flood the sprinkler system

piping.

As an option, the 4 and 6 inch (100 and

150 mm) Double Interlock Preaction

Systems may be equipped with a

Model F311 Accelerator (Fig. C) forthe

purpose of obtaining a reduction in the

time for the Dry Pilot Actuator to open

following the operation of one or more

automatic sprinklers.

With the optional Double Interlock Ac-

celerator Trim, the communication be-

Loading...

Loading...