16. If resetting after a test, fully open

the System Shut-Off Valve (Fig. A),

if applicable.

17. Open the Air Supply Control Valve

(Fig. C) and pressurize the sprink-

ler system in accordance with

Graph B.

18. Return the Solenoid Valve to its

normally closed position by reset-

ting the automatic control unit.

19. Fully open the Diaphragm Cham-

ber Supply Valve (Fig. D) and allow

time for full pressure to build up in

the Diaphragm Chamber of the

Multimatic Valve.

20. Operate (open) the Manual Control

Station (Fig. D). SLOWLY close

the operating lever, by pushing it

up, after air is no longer present in

the discharge from the drain tub-

ing. Close the hinged cover and

insert a new break rod (PSN 92-

289-1-008) in the small hole

through the top of the enclosing

box.

21. Inspect the drain connections from

the Dry Pilot Actuator and Manual

Control Station for leaks. Leaks, if

any, must be corrected before the

system is restored to service.

22. Reset the F311 Accelerator (Fig.

C) as follows, if the system is so

equipped; otherwise, proceed to

Step 23.

a. Close the Accelerator Control

Valve.

b. Slowly remove the plug from the

Strainer at the Accelerator inlet to

relieve any inlet pressure. This

procedure will trip the Accelerator

if it is not already tripped.

c. Clean out the Strainer at the Ac-

celerator inlet.

NOTE

A clogged strainer can prevent

the Accelerator from properly

tripping the system.

d. Open the Accelerator Bleed-off

Valve (Fig. C) and blow any resid-

ual water in the connection to the

system piping out through the

tube to the Drip Funnel. Close the

Bleed-off Valve after water

ceases to drain.

e. Open the Accelerator Control

Valve one-quarter turn and blow

any residual water in the connec-

tion to the system piping out

through the Strainer.

f. Close the Accelerator Control

Valve and replace the Strainer

Plug.

g. Slowly remove the Vent Plug lo-

cated in the front of the Accelera-

tor Cover and bleed off any resid-

ual pressure in the Accelerator

Differential Chamber.

h. Unscrew (counter-clockwise rota-

tion) the knurled Reset Knob at

the front of the Accelerator until it

resists further turning. A click,

which is the sound of the Lever

snapping back into the set posi-

tion, should be heard. Screw the

Reset Knob back in until it is finger

tight.

i.

i.

Replace the Vent Plug.

Verify that the system pressure

has returned to normal.

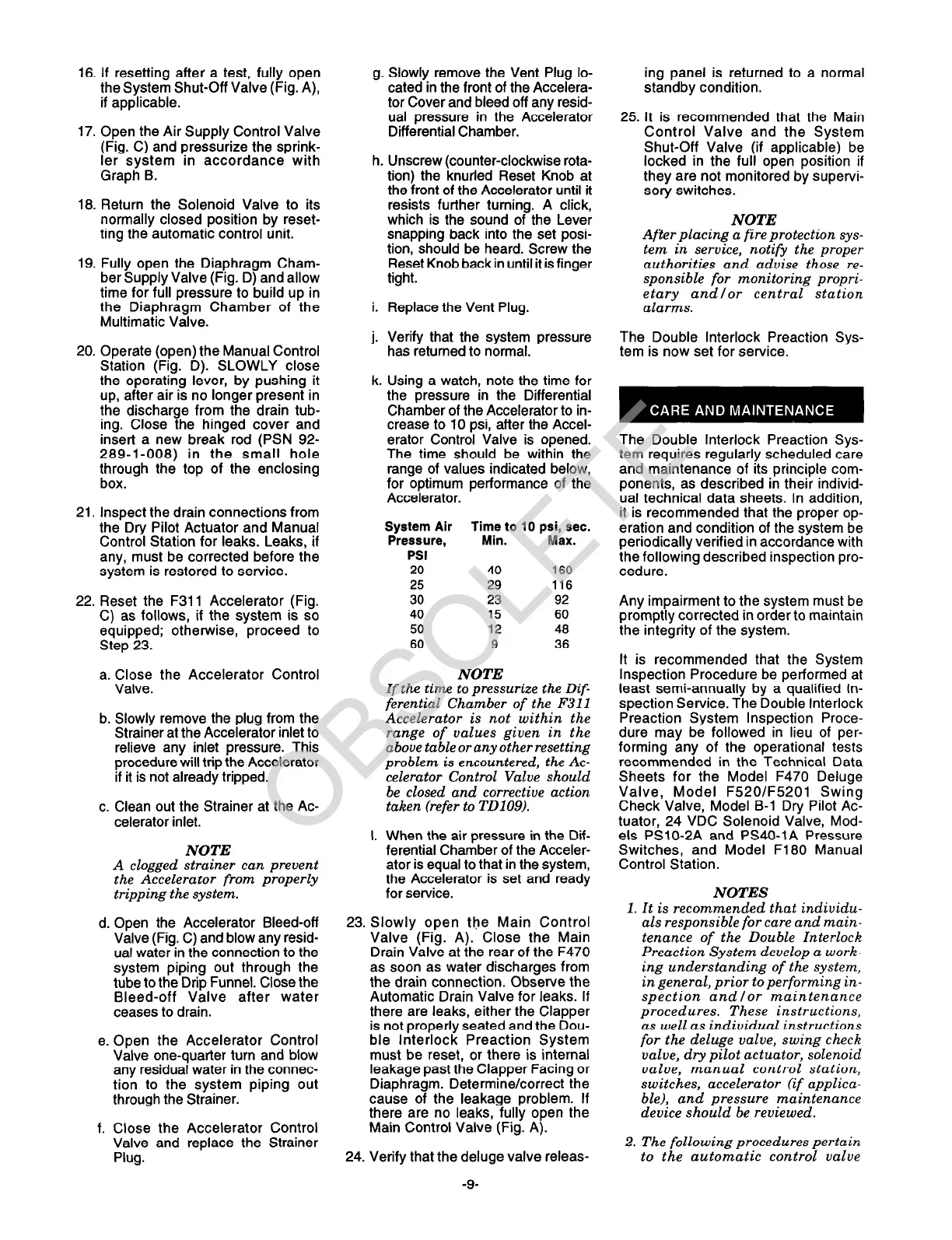

k. Using a watch, note the time for

the pressure in the Differential

Chamber of the Accelerator to in-

crease to 10 psi, after the Accel-

erator Control Valve is opened.

The time should be within the

range of values indicated below,

for optimum performance of the

Accelerator.

System Air

Pressure,

PSI

20

25

30

40

50

60

Time to 10 psi, sec.

Min. Max.

40 160

29 116

23 92

15 60

12 48

9 36

NOTE

Zf the time to pressurize the Dif-

ferential Chamber of the F311

Accelerator is not within the

range of values given in the

above table or any other resetting

problem is encountered, the Ac-

celerator Control Valve should

be closed and corrective action

taken (refer to TD109).

I. When the air pressure in the Dif-

ferential Chamber of the Acceler-

ator is equal to that in the system,

the Accelerator is set and ready

for service.

23. Slowly open the Main Control

Valve (Fig. A). Close the Main

Drain Valve at the rear of the F470

as soon as water discharges from

the drain connection. Observe the

Automatic Drain Valve for leaks. If

there are leaks, either the Clapper

is not properly seated and the Dou-

ble Interlock Preaction System

must be reset, or there is internal

leakage past the Clapper Facing or

Diaphragm. Determine/correct the

cause of the leakage problem. If

there are no leaks, fully open the

Main Control Valve (Fig. A).

24. Verify that the deluge valve releas-

-9-

ing panel is returned to a normal

standby condition.

25. It is recommended that the Main

Control Valve and the System

Shut-Off Valve (if applicable) be

locked in the full open position if

they are not monitored by supervi-

sory switches.

NOTE

After placing a fire protection sys-

tem in service, notify the proper

authorities and advise those re-

sponsible for monitoring propri-

etary and/or central station

alarms.

The Double Interlock Preaction Sys-

tem is now set for service.

The Double Interlock Preaction Sys-

tem requires regularly scheduled care

and maintenance of its principle com-

ponents, as described in their individ-

ual technical data sheets. In addition,

it is recommended that the proper op-

eration and condition of the system be

periodically verified in accordance with

the following described inspection pro-

cedure.

Any impairment to the system must be

promptly corrected in order to maintain

the integrity of the system.

It is recommended that the System

Inspection Procedure be performed at

least semi-annually by a qualified In-

spection Service. The Double Interlock

Preaction System Inspection Proce-

dure may be followed in lieu of per-

forming any of the operational tests

recommended in the Technical Data

Sheets for the Model F470 Deluge

Valve, Model F52OIF5201 Swing

Check Valve, Model B-1 Dry Pilot Ac-

tuator, 24 VDC Solenoid Valve, Mod-

els PSlO-2A and PS40-1A Pressure

Switches, and Model F180 Manual

Control Station.

NOTES

1. It is recommended that individu-

als responsible for care and main-

tenance of the Double Interlock

Preaction System develop a work-

ing understanding of the system,

in general, prior to performing in-

spection andlor maintenance

procedures. These instructions,

as well as individual instructions

for the deluge valve, swing check

valve, dry pilot actuator, solenoid

valve, manual control station,

switches, accelerator (if applica-

ble), and pressure maintenance

device should be reviewed.

2. The following procedures pertain

to the automatic control valve

Loading...

Loading...