Note: When changing sharpening stones of different thicknesses, control the angle of

sharpening of the knife. It should remain unchanged. Every time a sharpening stone is

changed the procedure for measuring the sharpening stone (between the thickness

compensator and the pivot) described in section 4.2. should be repeated. If the

sharpening stones are of the same size/thickness, there is no need to measure again.

After you clamp the pivot with the thumb screw, the sharpening stone can be removed.

The distance you get between the thickness compensator and the pivot is to

compensate for the variance in sharpening angle created by the sharpening stone. Now,

the sharpening angle is set with the utmost precision.

4 3 . .Attaching the sharpening stone

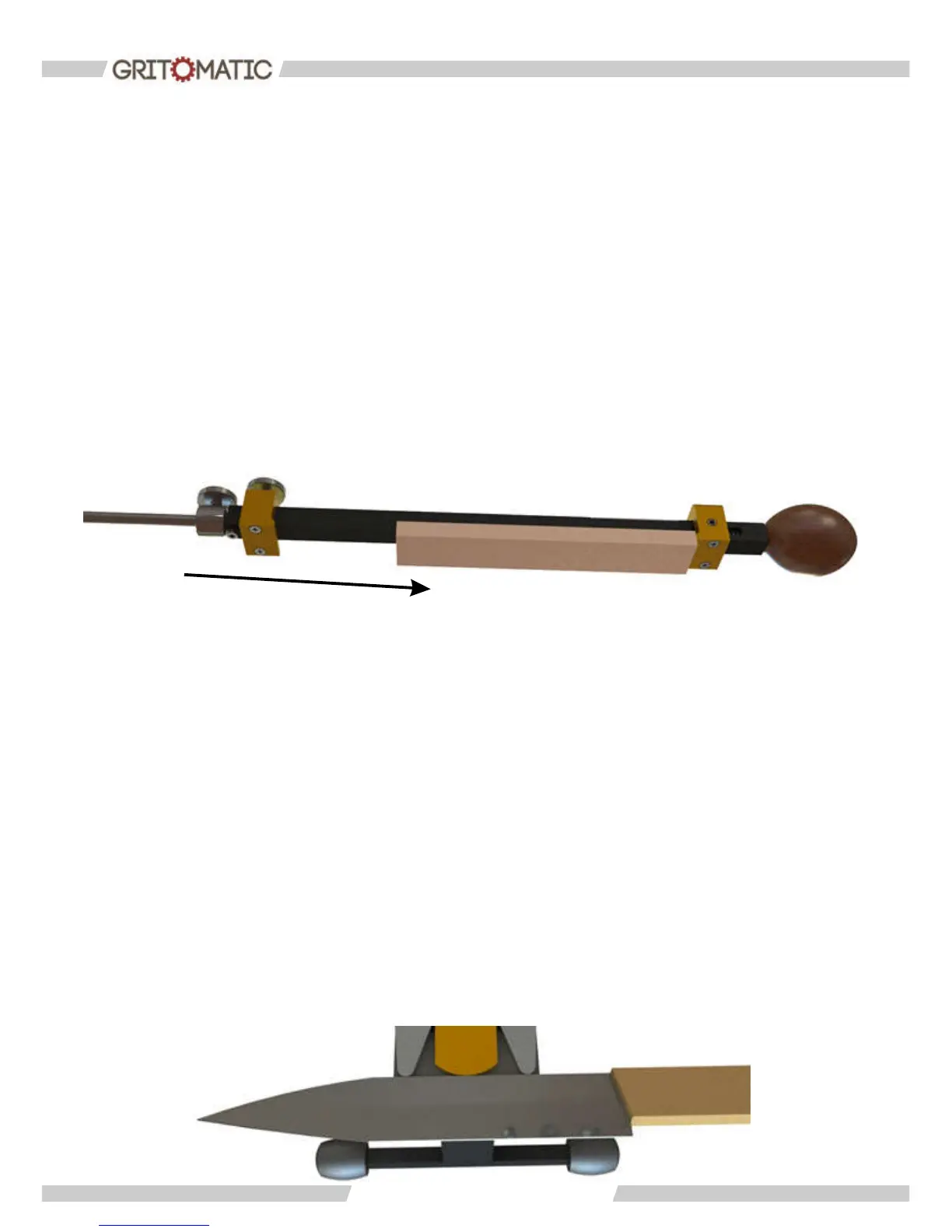

The sharpening stone should be fastened on the horizontal shaft in the stone holder.

Because sharpening stones can be of different lengths, the clamp with the xing screw is

movable. It moves along the entire length of the horizontal shaft and this allows a

sharpening stone of any length to be attached.

With two ngers press the nearest side of the stone holder through the spring and get it

as close as you can to the wooden handle. Put the sharpening stone into the stone

holder and fasten it with the thumb screw.

www.gritomatic.com

4 4 . .Fastening the knife

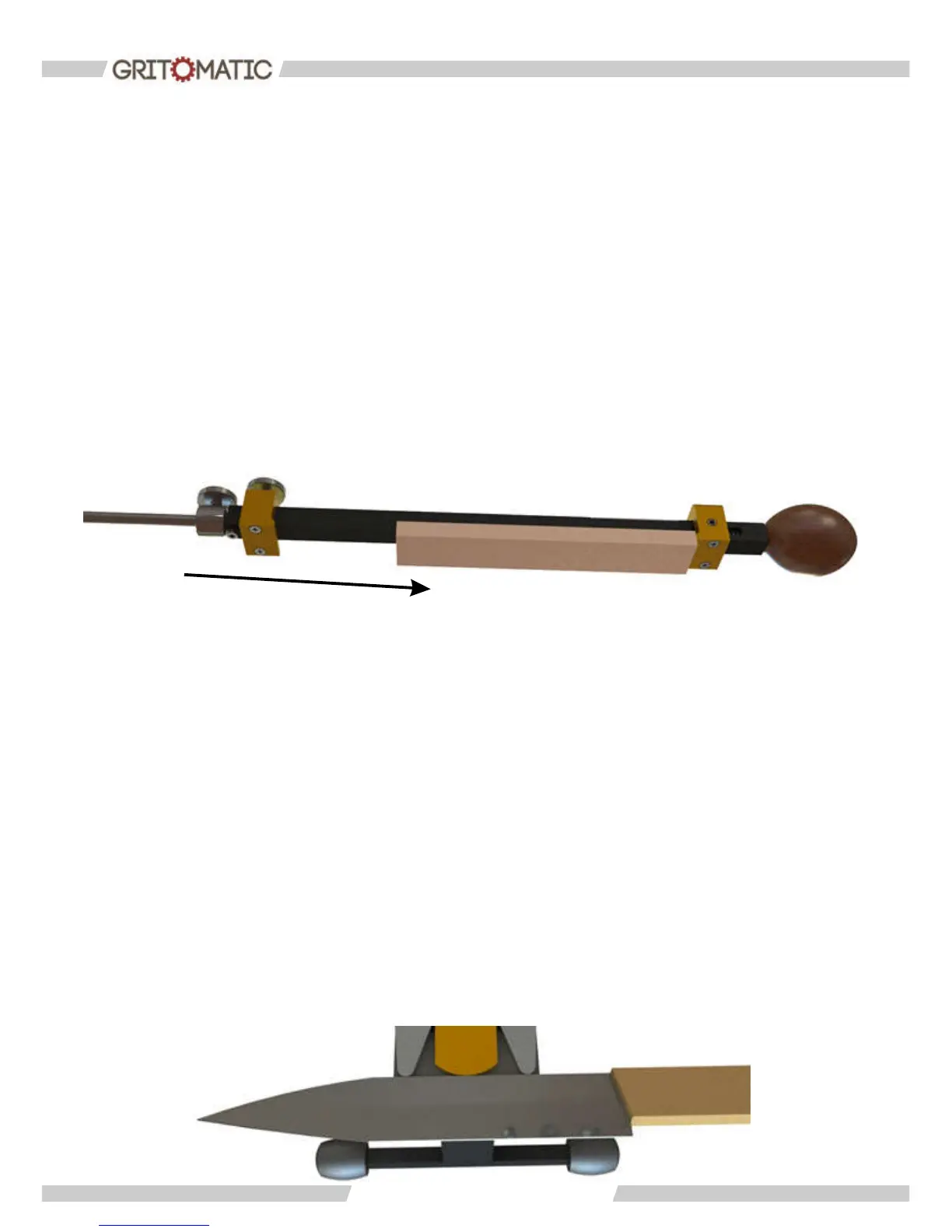

Position the knife on the rubber mat at the base of the knife sharpener. The edge of a

knife with a blade should be directed outwards (towards you). You will immediately feel

the magnet located in front part of the base. The cutting edge of the knife must slightly

overlap the edge of the base (approximately 1-3 mm). Attach the three point guide

tightly to the knife and secure it with the large thumb screw. The three-point guide

allows the knife to be precisely positioned on the working plate – both before and after

being ipped over – ensuring a smooth and symmetrical cutting edge. You need not

worry about the safety of your blade, because the guide is made of aluminum. For

additional protection, you can cover the blade with protective tape.

Loading...

Loading...