-36-

Model G0453Z/G0454Z (Mfg. 1/09+)

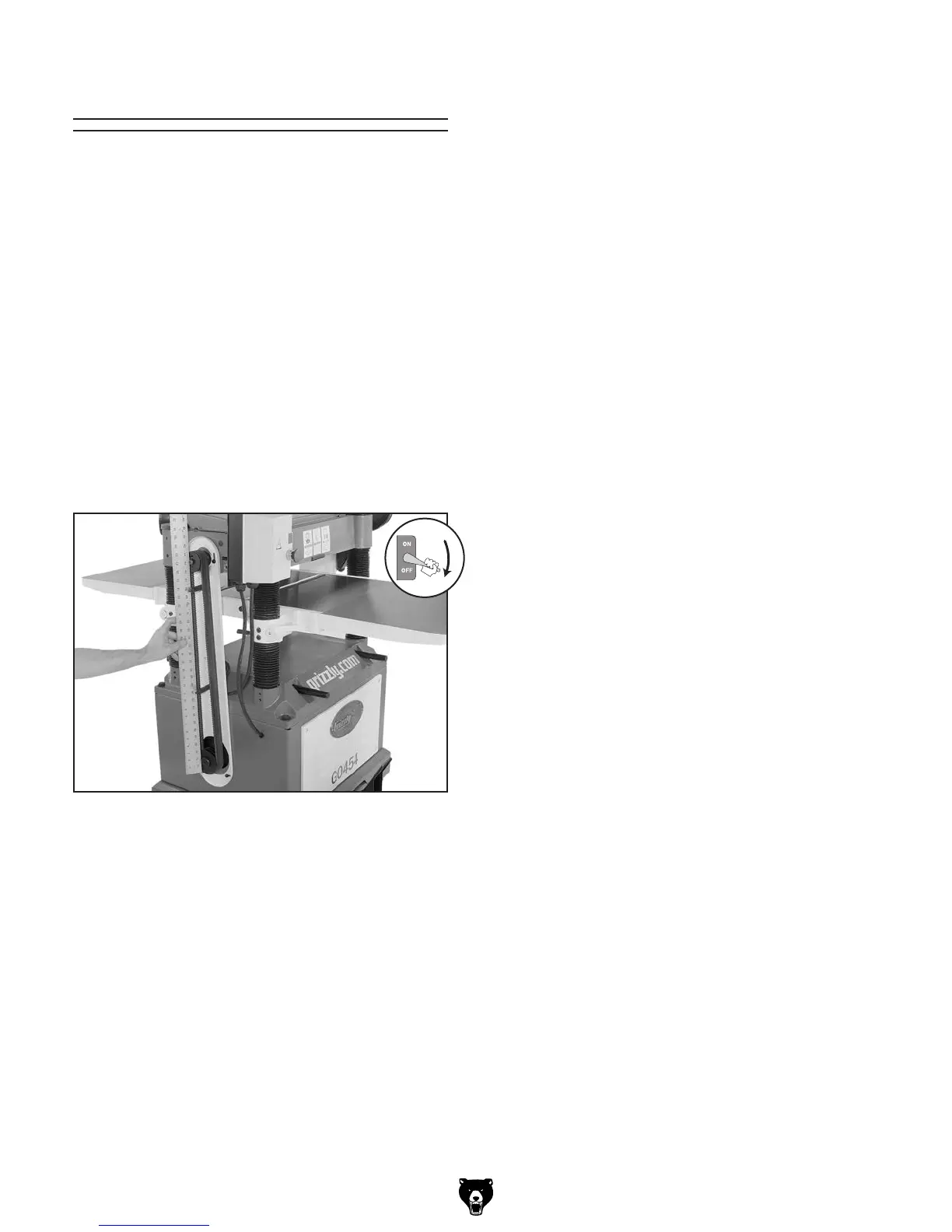

Pulley Alignment

Proper pulley alignment prevents premature V-belt

wear and unnecessary load on the motor. The pul-

leys are properly aligned when they are coplanar

(in the same plane and parallel to each other).

Tools Needed Qty

Straightedge 3' .................................................. 1

Hex Wrench 6mm .............................................. 1

Wrenches or Sockets 14mm ............................. 1

To check/re-align pulleys:

1. DISCONNECT PLANER FROM POWER!

2. Remove both cabinet covers and the belt

cover, then use the straightedge to check pul-

ley alignment, as shown in Figure 34.

— If the pulleys are not in the same plane,

loosen the cap screw or hex bolt securing

the pulley to the shaft, then adjust the pul-

leys in or out until they are even with each

other.

— If the pulleys are not parallel, loosen the

four motor mount hex nuts, then rotate the

motor on its mount until they are parallel.

3. Re-check the pulleys and repeat Step 2 if

necessary.

4. When you are satisfied with the pulley align-

ment, re-tighten all fasteners, then replace

the belt cover and cabinet covers.

Figure 34. Checking pulley alignment.

Loading...

Loading...