-32-

Model G1066R/Z/G1079R (Mfd. Since 02/11)

Overloading the motor or pushing the sand-

er to failure weakens the electrical sys-

tem. Repeatedly doing so is abuse to the

machine that will cause motor, capacitor, or

circuit breaker damage, which is not cov-

ered under warranty.

Setting Conveyor

Speed (G1066Z)

The conveyor speed control allows you to set the

conveyor speed from 0–10 (0–20 FPM). The cor-

rect speed to use depends on the type of stock

you are using (hardwood vs. softwood) and the

stage of finish you are at with that workpiece.

As a general rule, a slower speed will sand the

surface smoother, but runs the risk of burning the

wood; a faster speed will remove material faster,

but runs the risk of overloading the motor. Use

trial-and-error to determine the best settings for

your specific applications.

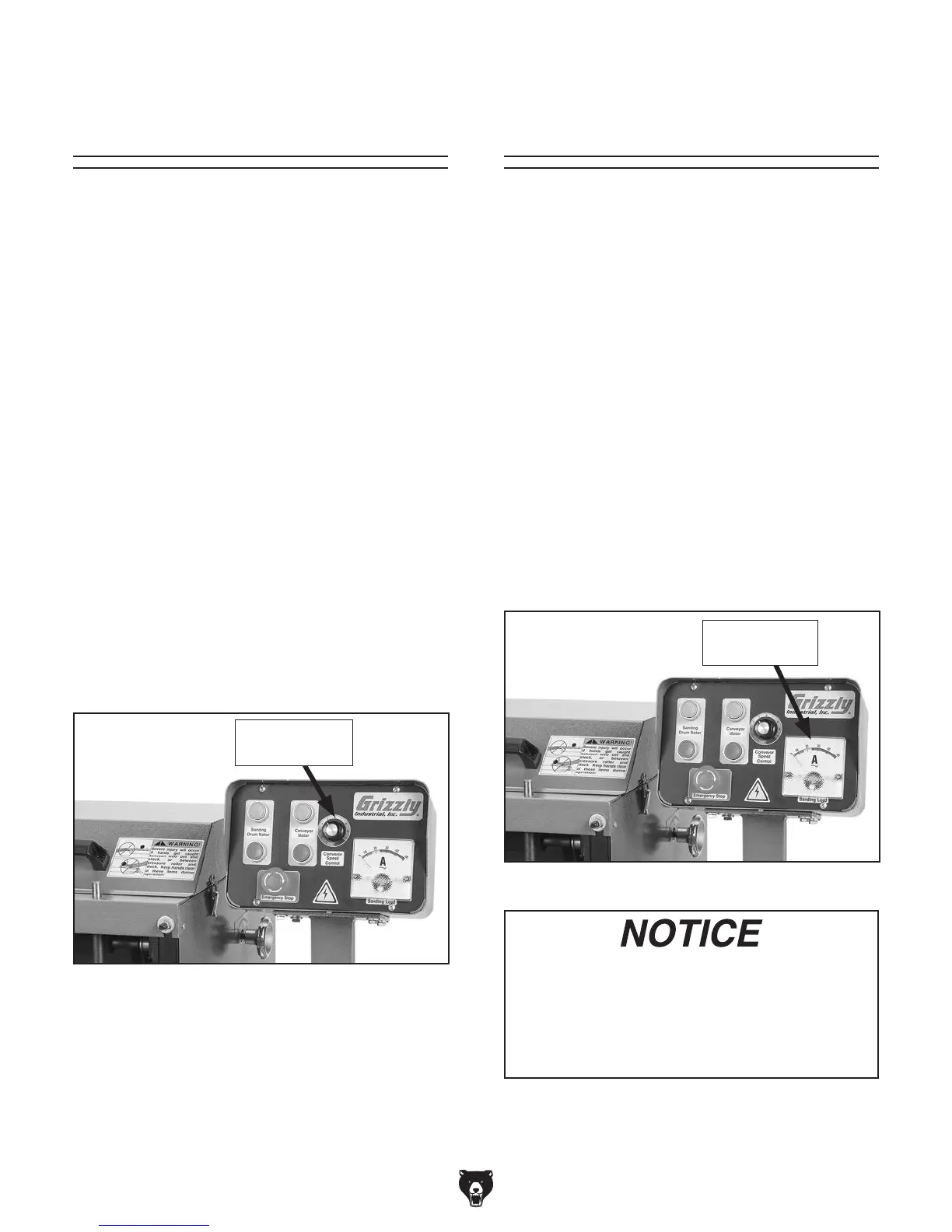

Figure 69. Location of conveyor speed control

(G1066Z).

To set conveyor speed:

1. Set conveyor speed control to "0," and then

turn conveyor motor ON.

2. Slowly turn conveyor speed control (see

Figure 69) clockwise to increase conveyor

speed.

— If conveyor speed is too high, turn control

counterclockwise to decrease conveyor

speed.

Conveyor

Speed Control

Monitoring Sanding

Load (G1066Z)

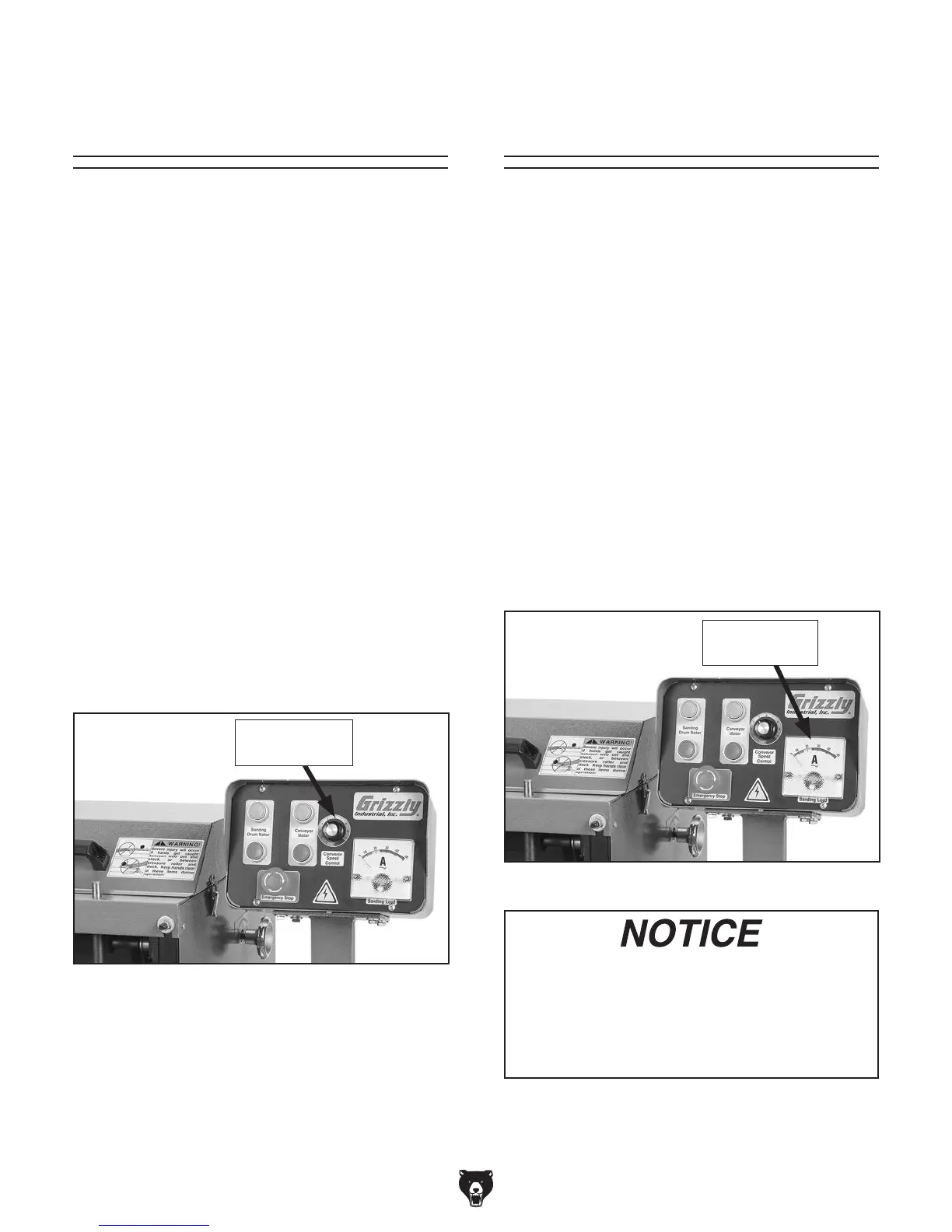

The load meter (see Figure 70) displays the

amperage draw of the sanding drum motor. The

needle moves to the right when you increase the

load on the sanding drums and moves to the left

when you decrease the load. Use this meter to

avoid overloading your machine with too heavy

of a cut.

IMPORTANT: NEVER exceed 25 amps—this

is the maximum that your machine can safely

handle!

Since various types of stock will react differently

with various loads, use trial-and-error to deter-

mine the best settings for your applications. As

a general rule, always start with a small load

and work your way up. We recommend that you

do not push your machine to its maximum load;

instead, make multiple passes or install a coarser

grit paper.

Figure 70. Location of load meter (G1066Z).

Sanding Load

Meter

Setting Conveyor Speed

Loading...

Loading...