9

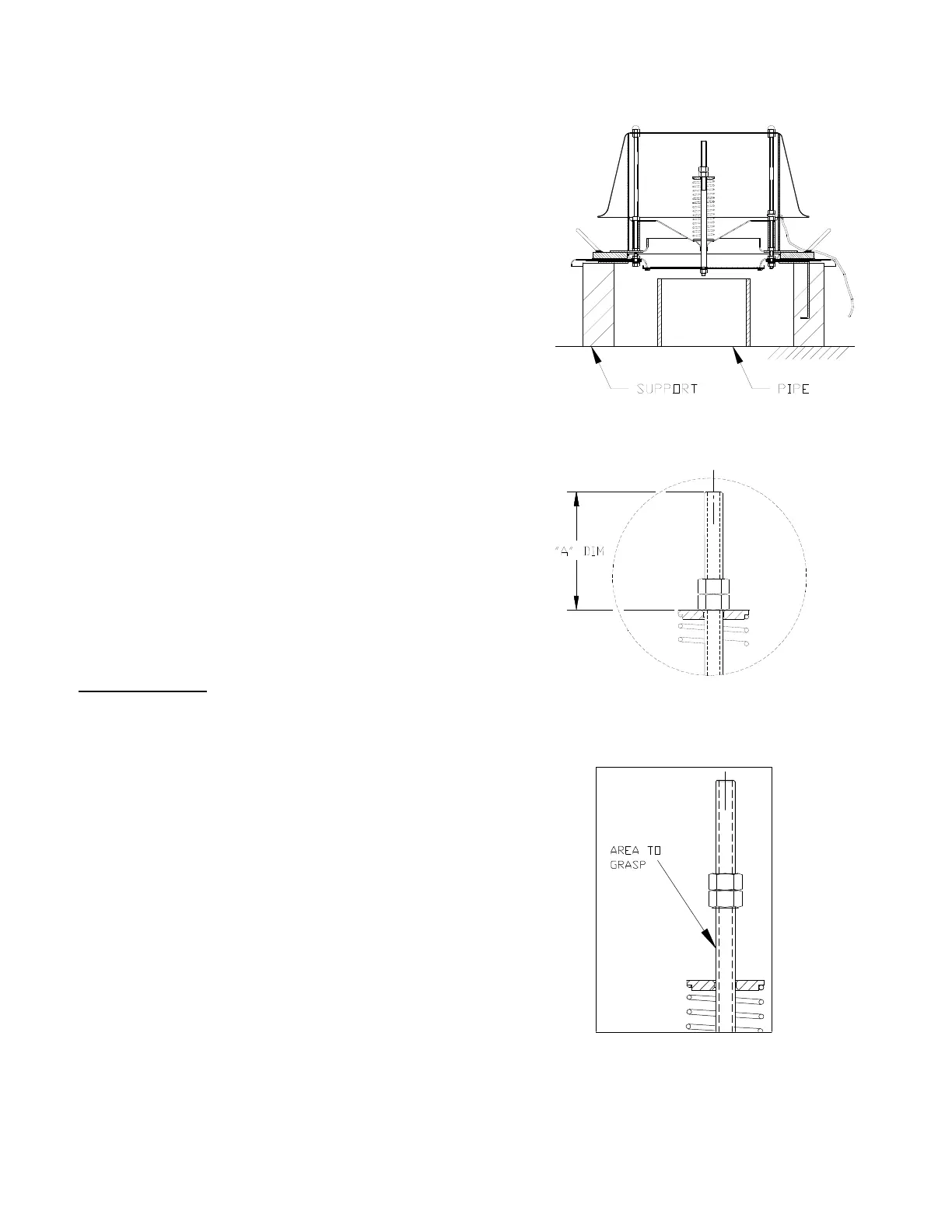

nut from the stem. Slowly raise the spring

button to release the spring compression. The

spring force will be in 5 – 30 lb range, depending

on vacuum setting.

6. Using weight plate handles, if included, lift pressure

pallet [2] with attached assembly and remove

vacuum pallet-stem [23, 14] assembly from the

bottom.

7. Remove the nuts on the weatherhood posts holding

the stem guide [17]. Note: For low pressure

settings, a weight plate is added on the stem guide

[17].

8. Lift the spacers [12]. Remove the nuts above the

water dam [28]. Note: Water dam is only used if

weight plate is mounted directly on pressure pallet

[2].

9. Remove the weatherhood posts [27] by loosening

the nuts beneath the pallet.

10. Carefully lift the weight plate [29] vertically.

Caution: This may require a crane due to the

weight. (See Warning on page 5.)

11. Turn pallet assembly upside down (Figure 9).

12. Remove remaining bolts, nuts, and washers [7, 9,

19, 20, 21] to separate the vacuum seat.

13. Lift the retainer plate [3] and diaphragms [10] from

the pressure pallet.

2050A Assembly

Rebuild the valve reversing the disassembly steps.

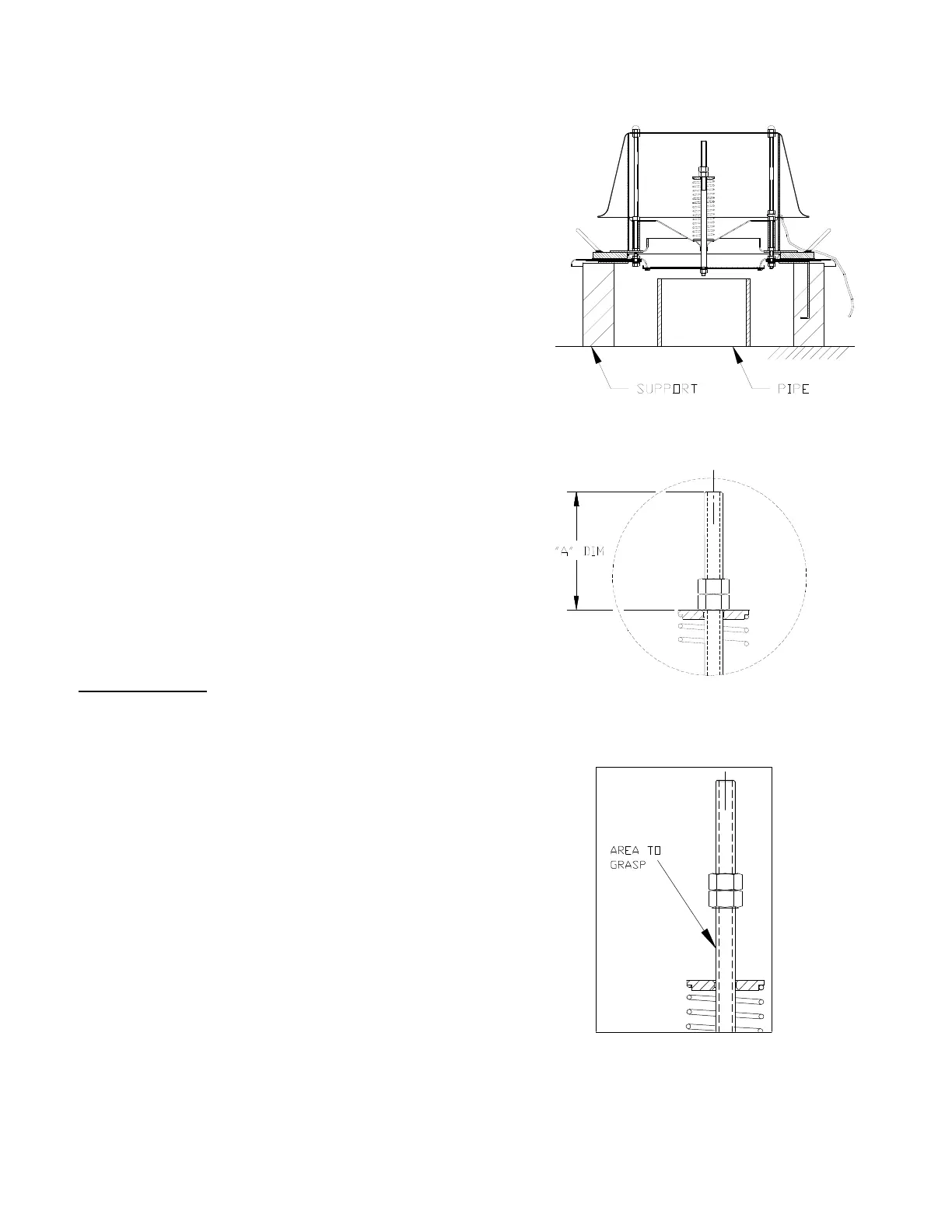

1. Begin by placing the pallet [2] upside down on

support blocks evenly spaced or on a pipe.

2. Wipe clean “air cushion” groove (seat area) in

pallet.

3. Center diaphragms [10] (qty 2) on pallet. See

Figure 3 for orientation of diaphragms, if elastomer

is used.

4. Place retainer plate [3], align with pallet hole

pattern.

Figure 7 : Vacuum Spring Compression

Figure 8 : Loosening Nuts for Spring

Figure 6 : Pallet Support (2050A)

Loading...

Loading...