WWW.GFWORLDWIDE.COM | +1 (208) 664-9291

2.8 FALL HAZARDS

• Equipment operators and maintenance

personnel are susceptible to falls from

equipment during repair and servicing.

Prevent falls and slips by following these

guidelines:

• ON-SITE FALL HAZARD requirements supersede all

of the guidelines listed below. Closely follow on-site

safety rules.

• Know and identify what slip, fall and trip hazards are,

and what preventative measures are required

• Survey work area on and around equipment for slip

and fall hazards and remove hazards from area

• Never jump from equipment to the ground

• Use three points of contact when climbing equipment

• Where there is a danger of falling use a FALL

PROTECTION SYSTEM per OSHA AND MSHA

requirements.

• Always follow national, state and local codes:

https://www.osha.gov/SLTC/fallprotection/

2.9 PINCH POINT HAZARDS

• Never place yourself between a piece

of heavy equipment or machinery and an

immovable object

• Never work within the swing radius of

rotating equipment

• Always work at a safe distance from equipment

• Caught-in hazards exist when workers remove or dis-

able guards. Use extra caution when removing this

safety equipment as required for servicing

• Never place your hands or body near moving parts

• Gloves, long sleeve shirts, hair, and loose tting cloth-

ing can be hazardous if caught in moving parts

• Never exceed maximum load limits according to the

equipment and machinery specications

• All workers should wear bright protective clothing.

Signs that are highly visible should be set up in a way

to warn and discourage nonworkers from entering site

• Never forget one simple rule: PARKING BRAKES. They

are easy to operate and can save lives

• Always use wheel chocks when working on or near a

vehicle

• Always verify that vehicle is clear before starting

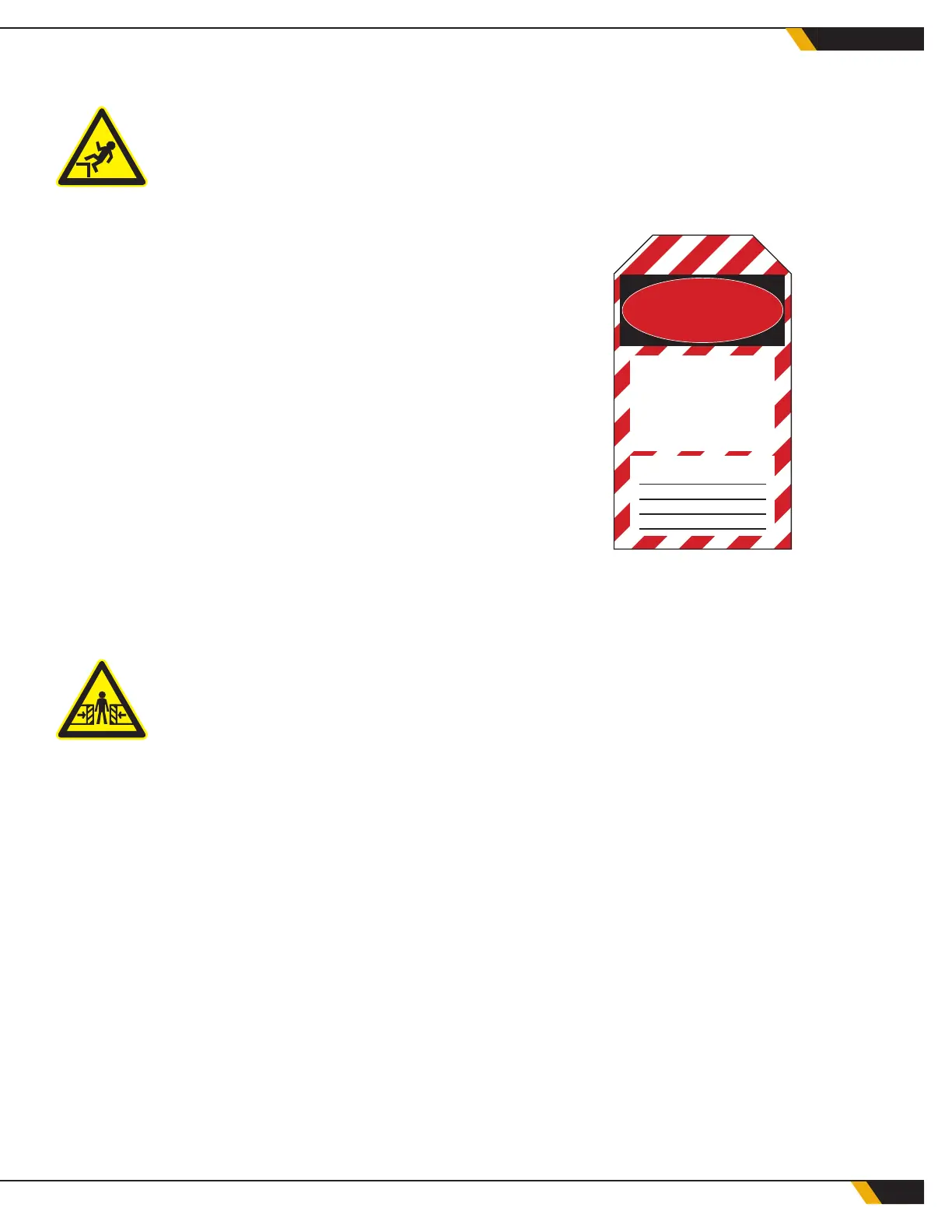

2.10 LOCK-OUT / TAG-OUT

1. IDENTIFY the types of energy sources used, potential

hazards, and control devices.

2. NOTIFY all affected employees.

3. TURN OFF all operating controls.

4. LOCATE all energy sources

5. ISOLATE all energy sources by blocking, bleeding

and ventilating stored energy as found in springs,

hydraulic systems, electrical systems and pneumatic

systems.

6. LOCK-OUT all switches and energy controls in the OFF

or SAFE position.

7. TEST operating controls. Put all controls in ON posi-

tion. Be sure no one can get hurt before testing.

8. RETURN all operating controls to the OFF position.

9. PERFORM required task.

10. REMOVE lock-out devices only after the equipment is

fully assembled and all affected employees have been

notied. Each lock-out device must be removed by the

person who put it on.

DANGERDANGER

DO NOT

OPERATE

EQUIPMENT

LOCK-OUT

TAG & LOCK ONLY TO BE REMOVED BY:

DATE:

11

SAFETY

Loading...

Loading...