WWW.GFWORLDWIDE.COM | +1 (208) 664-9291

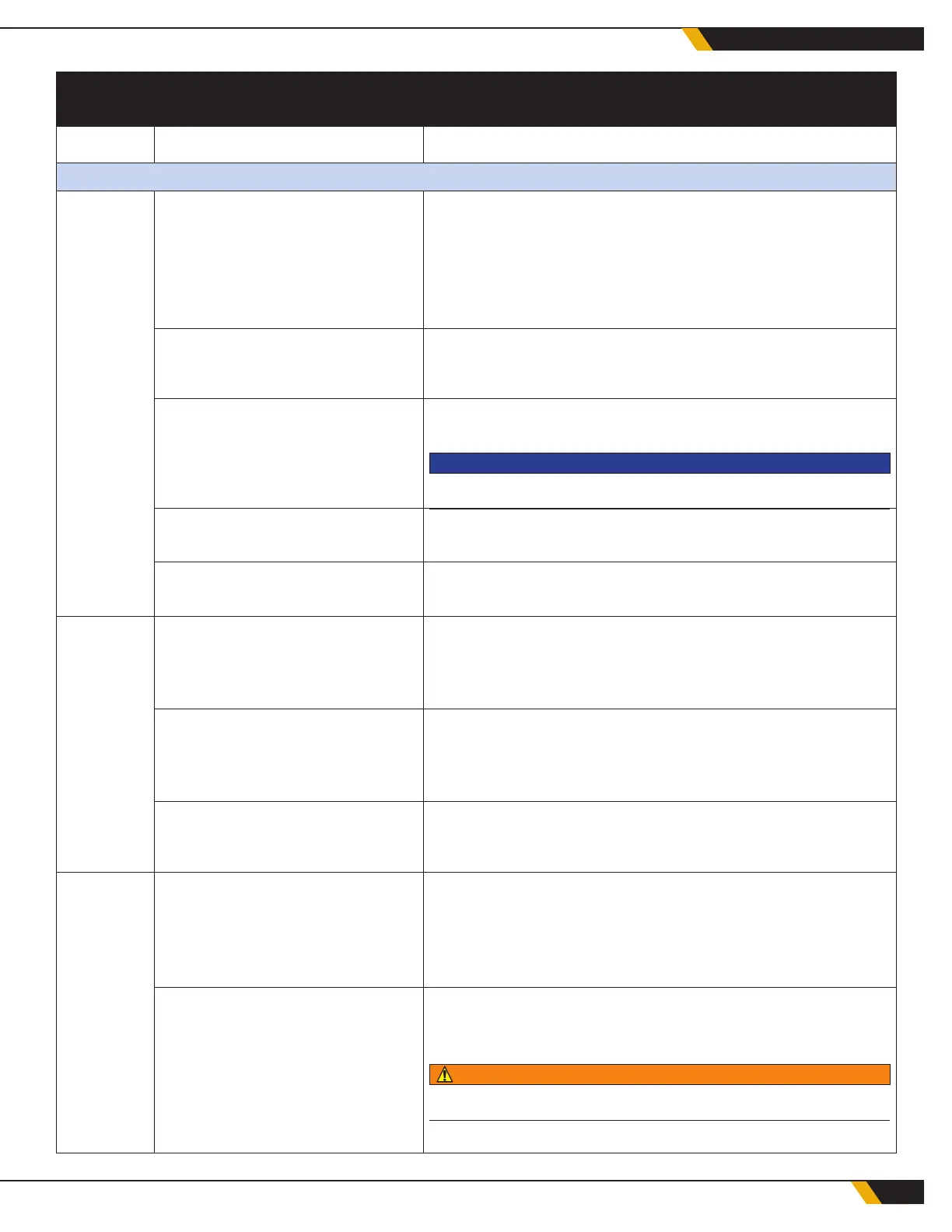

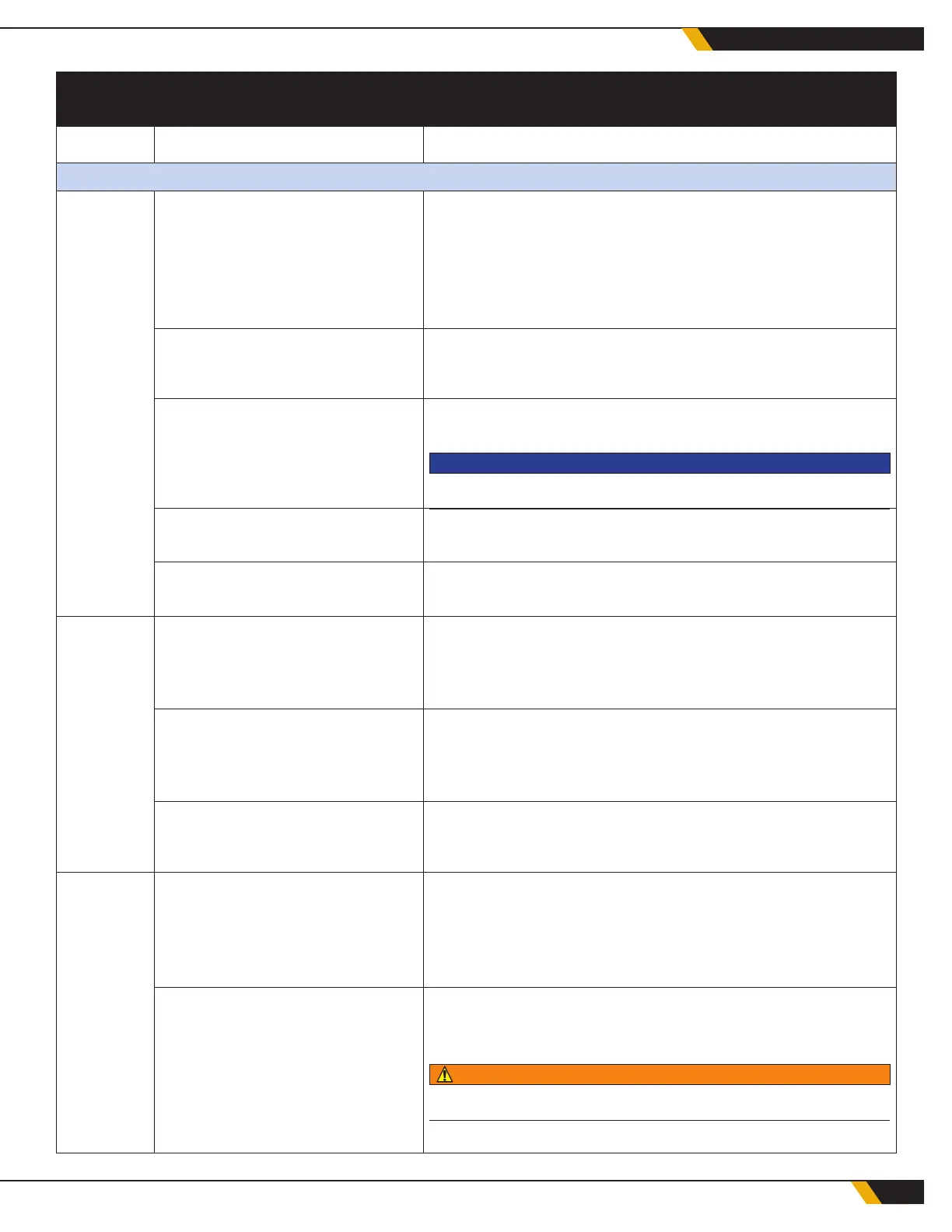

WATER TRUCK TROUBLESHOOTING

PROBLEM CAUSES SOLUTIONS

SPRAY HEADS

Spray head(s) have low to no ow.

(Rigid frame trucks with

ground speed control only.)

The water control system

settings may be incorrect.

Set the spray mode to manual mode. Try the spray heads

and if they spray normally, then the water control system

settings may be set incorrectly. This setting is the speed

(in MPH) at which you want to have 100% water ow to the

spray heads. Refer to the Water Control System operations

manual on how to set.

Ground speed control is showing

truck is moving while the truck

is sitting still.

Realign the ground speed control radar. Check for obstruc-

tions in front of the radar lens.

The connection to the ground

speed is faulty and the

radar under the truck is not

communicating correctly.

Check the radar for misalignment, a bad fuse or damaged

wiring.

NOTICE

This is a 12-volt system.

The lens of the ground speed

control radar is dirty.

Clean off the dirt and protect the lens from dirt as much

as possible.

The control coil or solenoid may

be bad.

Check for a bad hydraulic cartridge(s) or coil on the

diverter valve. Repair or replace as needed.

The spray head(s) have

low to no ow.

The spray bar full of debris. Remove the plugs on the end of the spray bar and remove

debris. It may be necessary to remove the valve cover

plate, diaphragm, spring and fan spray to clean out debris.

Apply pipe sealant to plugs before reinstalling.

There is a restriction or plugged

screen on the suction side

of the pump or in the pump's

impeller ns.

Remove the suction line going to the water pump and

check for debris. Check inside the tank to see if debris

is obstructing the suction screen of the sump. Remove

obstruction from the piping and screen.

The water pump is too slow. Set the chassis engine speed to full RPM (governed speed).

If the pump is still running slowly, there may be a hydraulic

issue. Refer to the HYDRAULICS section of this guide.

Excessive water ows back into the

tank when the pump is running,

and spray heads are closed.

Water hammer protection valve

could be faulty.

Check the water pressure by connecting a pressure gauge

to the spray bar, using a tting on the inlet side of a spray

valve. With the spray heads turned off, increase chassis

engine RPM and check the water pressure. If it is below 60

PSI, check for a defective water hammer protection valve.

Internal plumbing could be

damaged.

Enter the tank and repair damaged plumbing.

If the damage was caused by freezing, drain the tank and

spray valves in the winter to prevent future damage.

WARNING

Follow all safety requirements for entry and welding inside the tank.

45

TROUBLESHOOTING

Loading...

Loading...