8

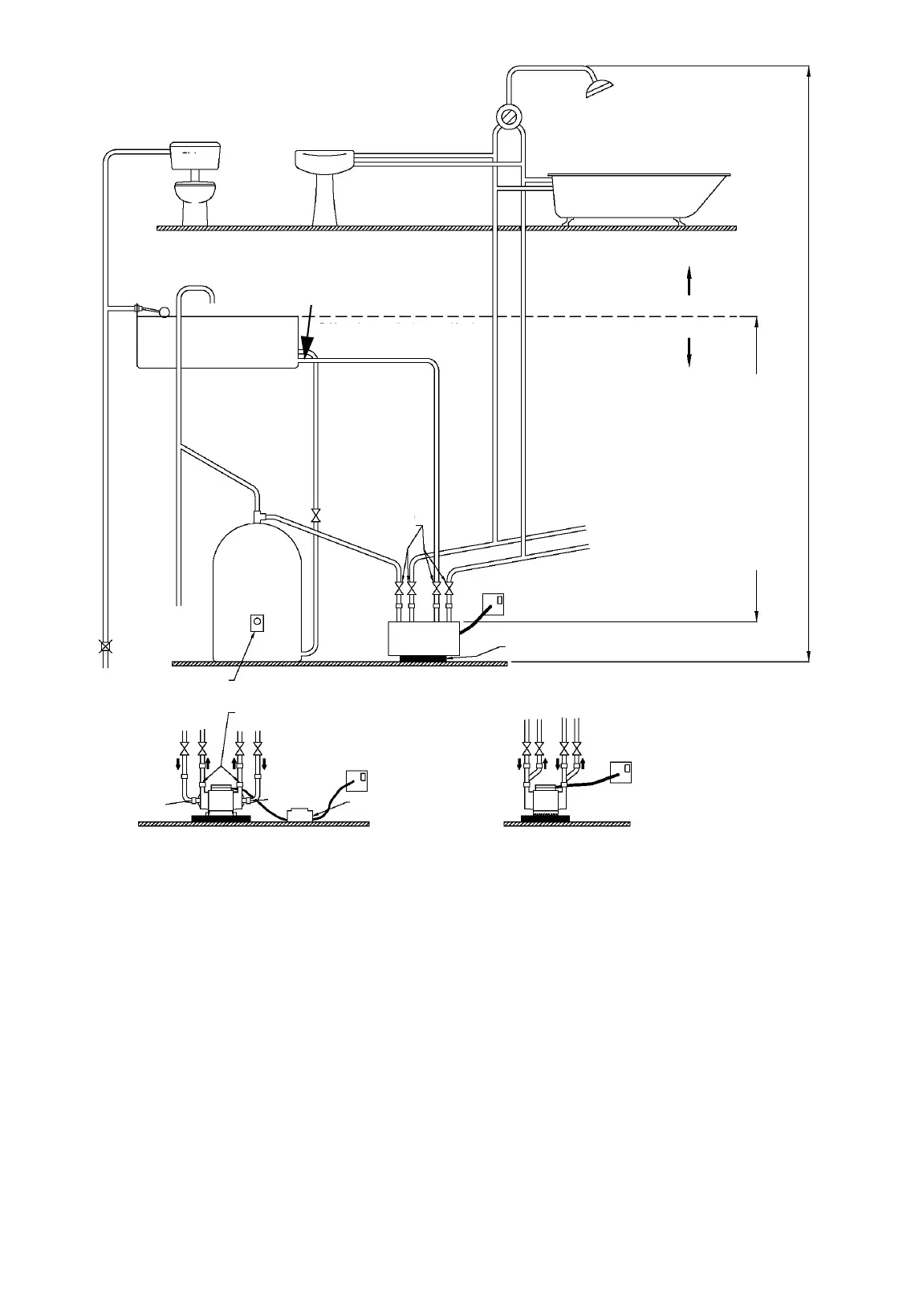

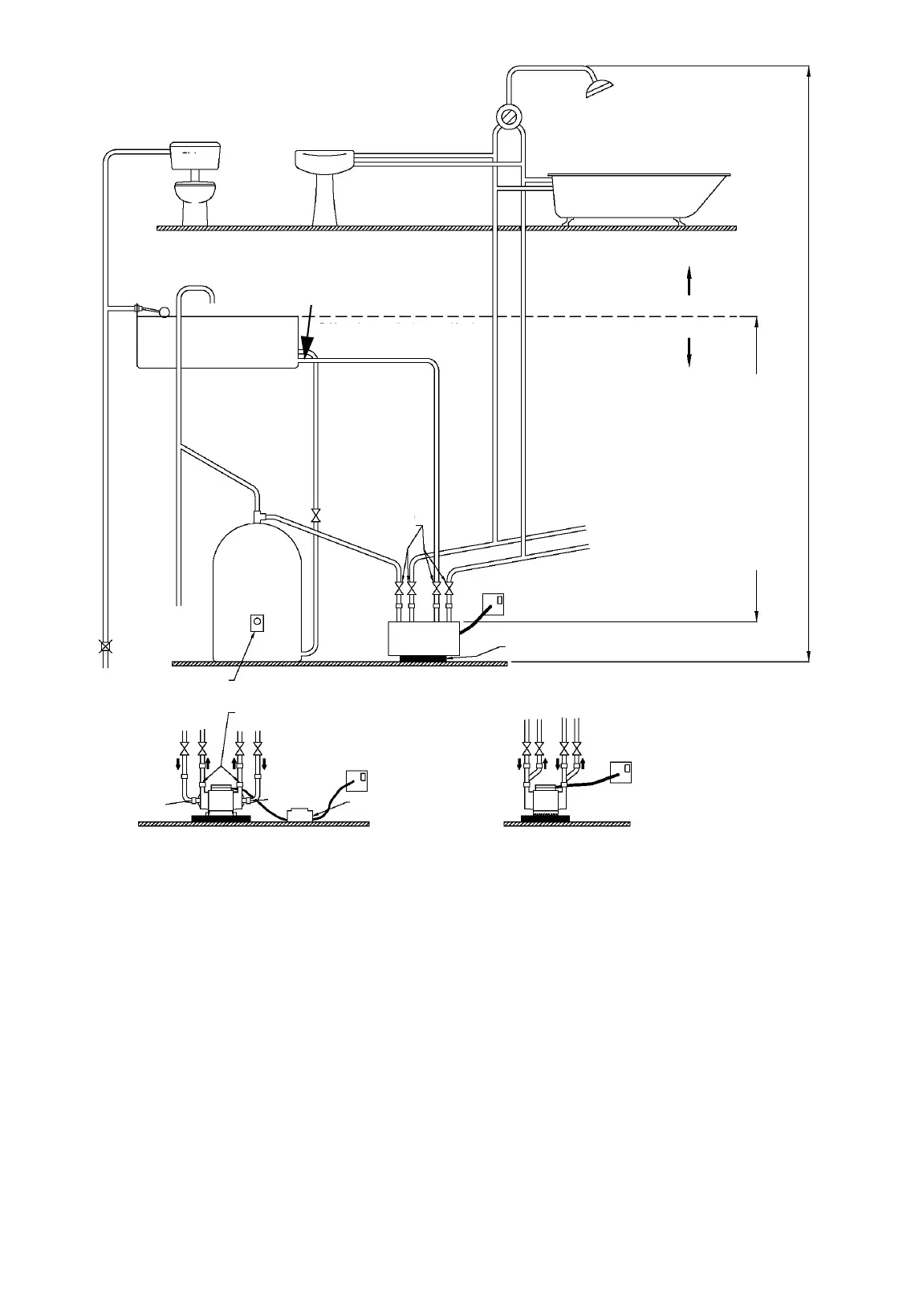

Fig. 4 Negative-head pumps, STN, SSN and STL 2.0 CN

Negative-head pumps

• Either Surrey, York, Warix or Essex flanges can be used,

depending on the cylinder type and installation.

• An Essex flange is recommended for pumps rated 3 bar and

above, i.e. models STN 3.0 B, SSN 3.0 B and STN 4.0 B.

• The hot-water supply to the shower pump must be via a

dedicated supply from the flange.

• Do not fit non-return valves on the inlet pipework to the pump.

The pump must be able to vent back to the cold-water storage

tank and hot-water cylinder.

• Avoid positioning outlets in the cold-water storage tank directly

below the inlet from the water mains supply in order to prevent

air from being drawn into the pump or hot-water cylinder.

• 22 mm pipework should be used to and from the pump.

• Connect the side of the pump with the larger expansion tank to

cold water and the side of the pump with the smaller

expansion tank to hot water.

• The expansion pipe from the hot-water cylinder should always

rise in order to prevent trapped air.

• The outlet pipework from the pump to the shower valve should

rise, where possible, to prevent trapped air.

• Pipework from the pump to the shower valve should go up and

over, rather than under floor.

• Avoid blanked-off pipes (dead legs) which can trap air and

cause problems.

• Avoid kinks in the flexible hoses as this will restrict the flow of

water to and from the pump.

• All pipework should be secured down to minimise noise and

vibration.

• Low-voltage pumps, model STL 2.0 CN, must be connected to

the 230 V electricity supply via the supplied transformer only.

• After commissioning, the pump ensures that all hose

connections are tight to prevent air from being drawn into the

system.

TM04 6989 1310

Cold-water

storage tank of at

least 50 gallons

Supply to another

shower, if required

Hot

Cold

Shower

valve

Domestic

hot-water

supply

Bath

Basin

Cistern

Cold-water supply connection to

pump at least 25 mm below cold-

water supply connection to cylinder

to prevent supply of hot water only

Mount the pump on concrete slab to

reduce noise.

System

vent

230 V,

switched

spur

Low-voltage pumps

must be connected

via transformer only.

See section 8. Technical data for

minimum and maximum inlet

heads from water level to pump

suction port.

Max. 8 m (26 ft)

Negative head

Positive head

Pipework connections, STN and SSN pumps

Flow

direction

Outlet

Inlet

Inlet

Pipework connections, STL 2.0 pumps

Hot-water

cylinder

Recommended location of pump

at base of hot-water cylinder

Hot-water cylinder set

to a maximum of 60 ºC

Water mains supply

Flow

direction

Outlets

Inlet

Inlet

230 V,

switched

spur

Low-voltage

transformer

Cold-water supply to

cylinder, min. 22 mm,

28 mm recommended

Full-bore gate valve

Surrey

flange

Pump

22 mm

service

gate valves

Cold-water supply to

pump, min. 22 mm

Hot-water

supply to

pump, min.

22 mm

Expansion pipe

Outlet

Grundfos.bk Page 8 Thursday, April 22, 2010 10:28 AM

Loading...

Loading...