\

2

The spindle bearing assembly is carefully set before despatch

of

the Lathe

from

our

Works

which

should ensure a high standard

of

performance

without

the

need

for

further

attention.

THE USER IS

ADVISED

NOT

TO

DISTURB

THIS

SETTING

DURING

NORMAL

USE

OF

THE

MACHI

NE

ANO

TO CONSULT OUR SERVICE

DEPARTMENT

IN

THE

UNLIKELY

EVENT OF

A

BEARING

PROBLEM.

WHERE ADJUSTMENT

IS

UNDERTAKEN

THEN

IT

IS

ESSENTIAL

THAT

THE

FOLLOWING

PROCEDURES

ARE

STRICTLY

COMPLIED WITH.

TO CHECK FOR CORRECT SETTING

Checks should

be

carried

out

with

the

headstock

in

a warm condition achieved

by

running

at

a

spindle

speed

of

800

rpm

for

approximately ten minutes.

The correct bearing torque setting is 0.9/1.1

Nm

(8/10

in

lbs)

and

can

be determined

as

follows

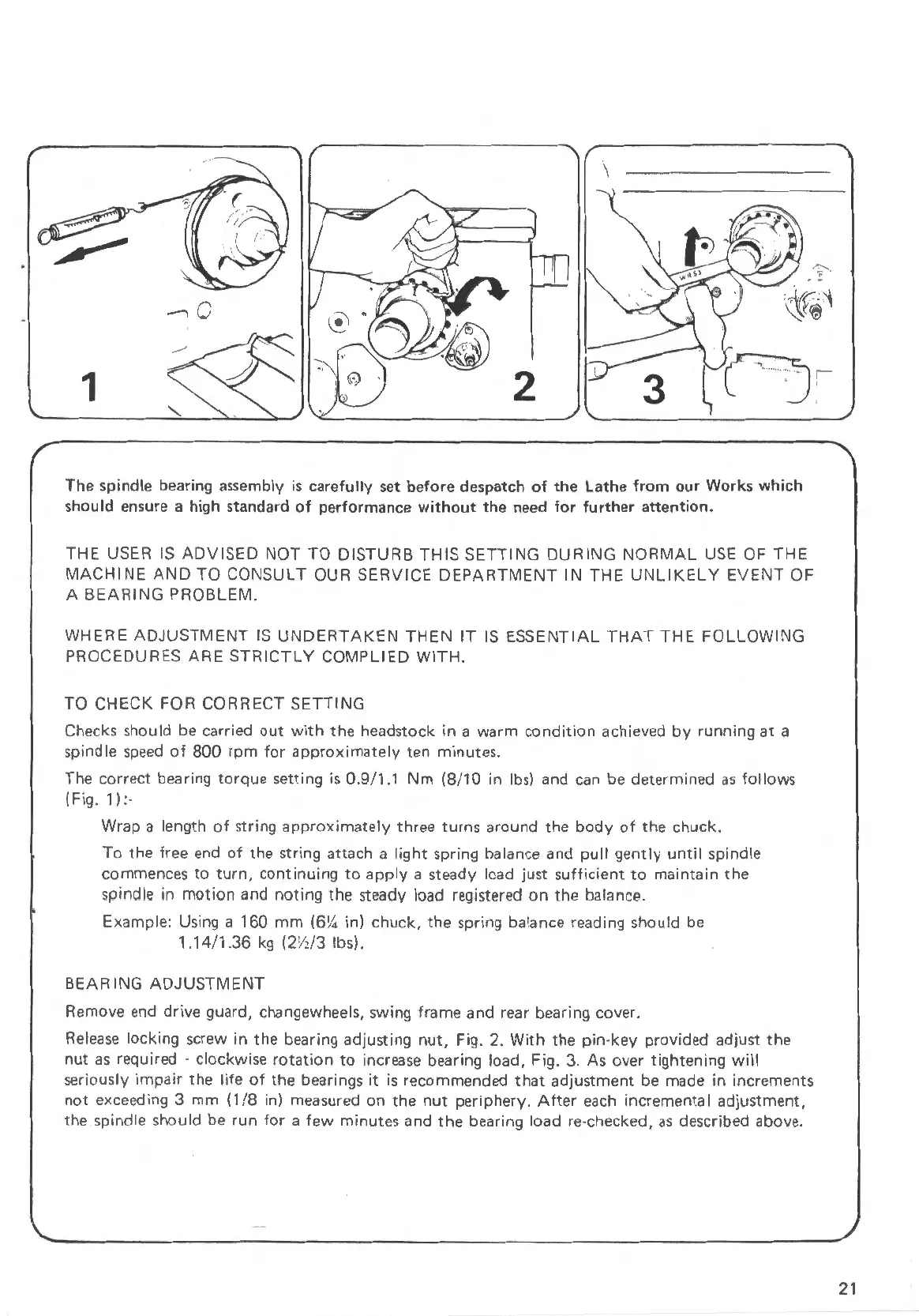

( Fig.

1)

:-

Wrap a length

of

string approximately three turns around

the

body

of

the

chuck.

To

the free end

of

the string attach a light spring balance and

pull

gently

until

spindle

commences

to

turn,

continuing

to

apply a steady load just sufficient

to

maintain the

spindle

in

motion and noting the steady load registered

on

the balance.

Example: Using a 160

mm

(6¼ in) chuck,

the

spring balance reading should be

1.14

/1 .36

kg

(2½/3 lbs).

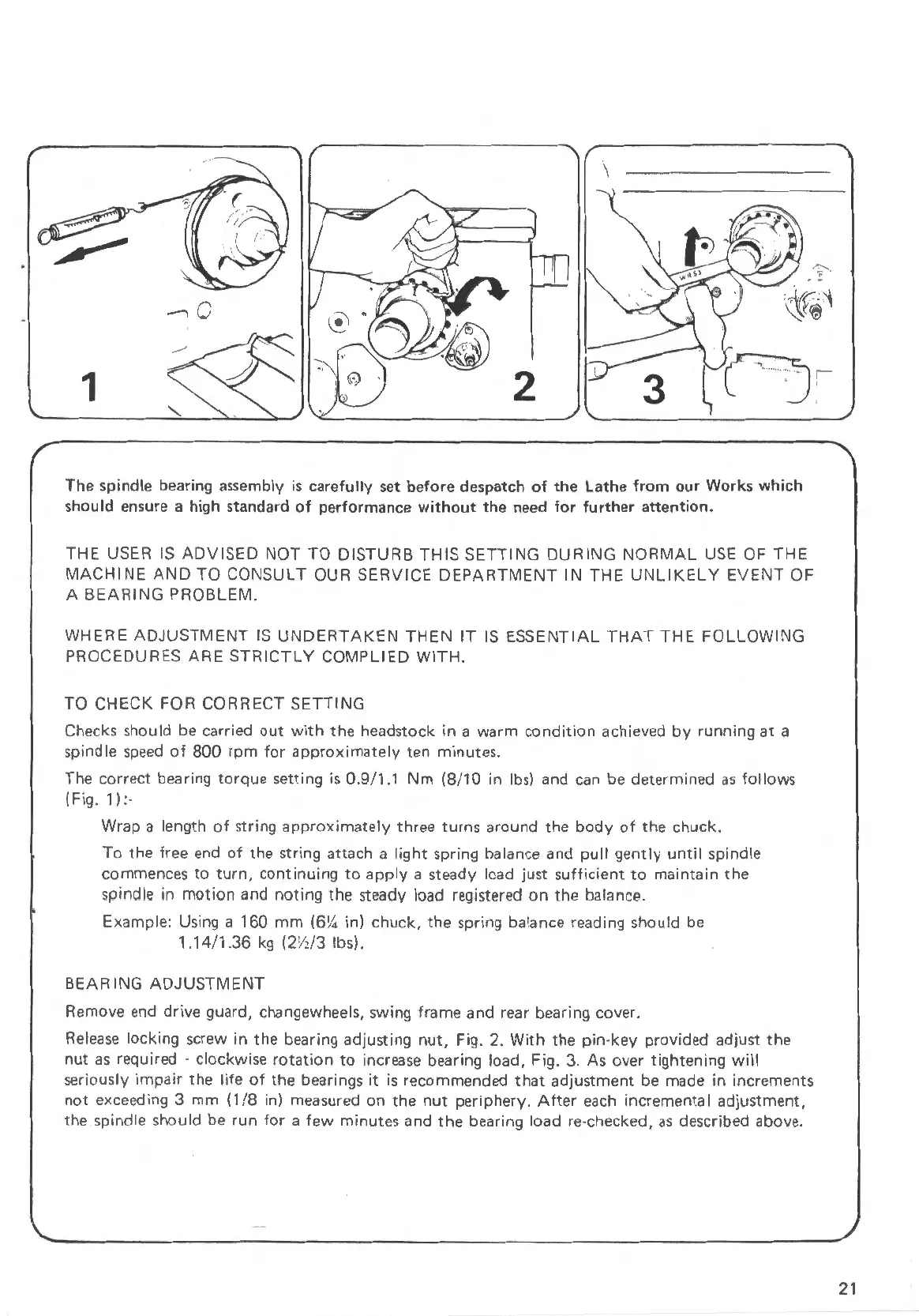

BEARING ADJUSTMENT

Remove

end

drive guard, changewheels, swing frame and rear bearing cover.

Release

locking screw

in

the bearing adjusting

nut,

Fig. 2.

With

the

pin

-key provided adjust the

nut

as

required · clockwise

rotation

to

increase bearing load, Fig. 3. As over tightening

will

seriously impair the

life

of

the bearings

it

is

recommended

that

adjustment

be

made

in

increments

not exceeding 3 mm

(1/8

in) measured on

the

nut

periphery.

After

each

incremental adjustment,

the spindle should

be

run

for a few minutes and the bearing load re-checked,

as

described above.

21

Loading...

Loading...