The installation of the intake air temperature sensor (21) should be fitted inside the

i

ntake air duct (approx. 1-1,5 meters from the unit). The sensor is prewired as

standard.

OPERATION – ADJUSTMENT (picture 5)

Three fan speeds are possible with the KWLC 350 S/L using the 3 step switch,

w

hich should be installed in a place easy to reach within the house.

MIN speed step 1 Basic air flow, for less intake air needs

NORMAL speed step 2 Normal air flow

MAX speed step 3 Full R.P.M., for maximum intake air.

I

n addition the control panel offers the following functions:

–

Left button (+ Symbol) activates/deactivates the after heater (in relation to the dip

s

witch settings). If the after heating is activated it turns on automatically if the set

temperature is not reached through the heat exchanger.

R

ed light (!) slow flashing Change filter!

(if the DDS pressure sensor is fitted)

f

ast flashing One of the safety temperature cut

outs (2) of the pre or after heater has

t

ripped .

constant light both cut outs tripped.

G

reen light (+) Lights up, when the after heater is activated.

Yellow light (°C) Lights up if the after heater is in use.

*) The switch control light operates when the heating coil is in use. For units with a

water heater battery this control light can be switched via a remote signal.

– Regulating the additional heating for units with electric heater battery

(Type KWLC 350..EH):

The thermostat for the additional heating (Pic.5, no.1) is on the top of the unit sen-

sing the extract air after the heat exchanger. The thermostat is factory set at 15°C,

but can be adjusted as required.

The heater is protected against overheating by a thermal overload thermostat that

switches off automatically when a temperature of 55°C has been reached. As an

additional safety control, a second thermostat switches off the whole unit if a tem-

perature of 80°C is exceeded. The thermostat can be manually reset by pressing

the red push button, which is accessible by removing the white plastic lid.

SPEEDS AND SETTINGS

Speed step 2 of the unit can be set to the size of the dwelling by opening up the

unit and changing the marked speed step 2 wire at the transformer in the unit ac-

cording to the internal wiring diagram. Isolate the unit from the power supply befo-

re opening.

Note: if the power supply of the unit is cut it will restart afterwards in NORMAL

speed (speed 2) and the electric after heater is activated.

Attention: For good room conditions and to reduce condensation water damage,

the unit should not be completely switched off, except when servicing / mainten-

ance or in case of breakdown.

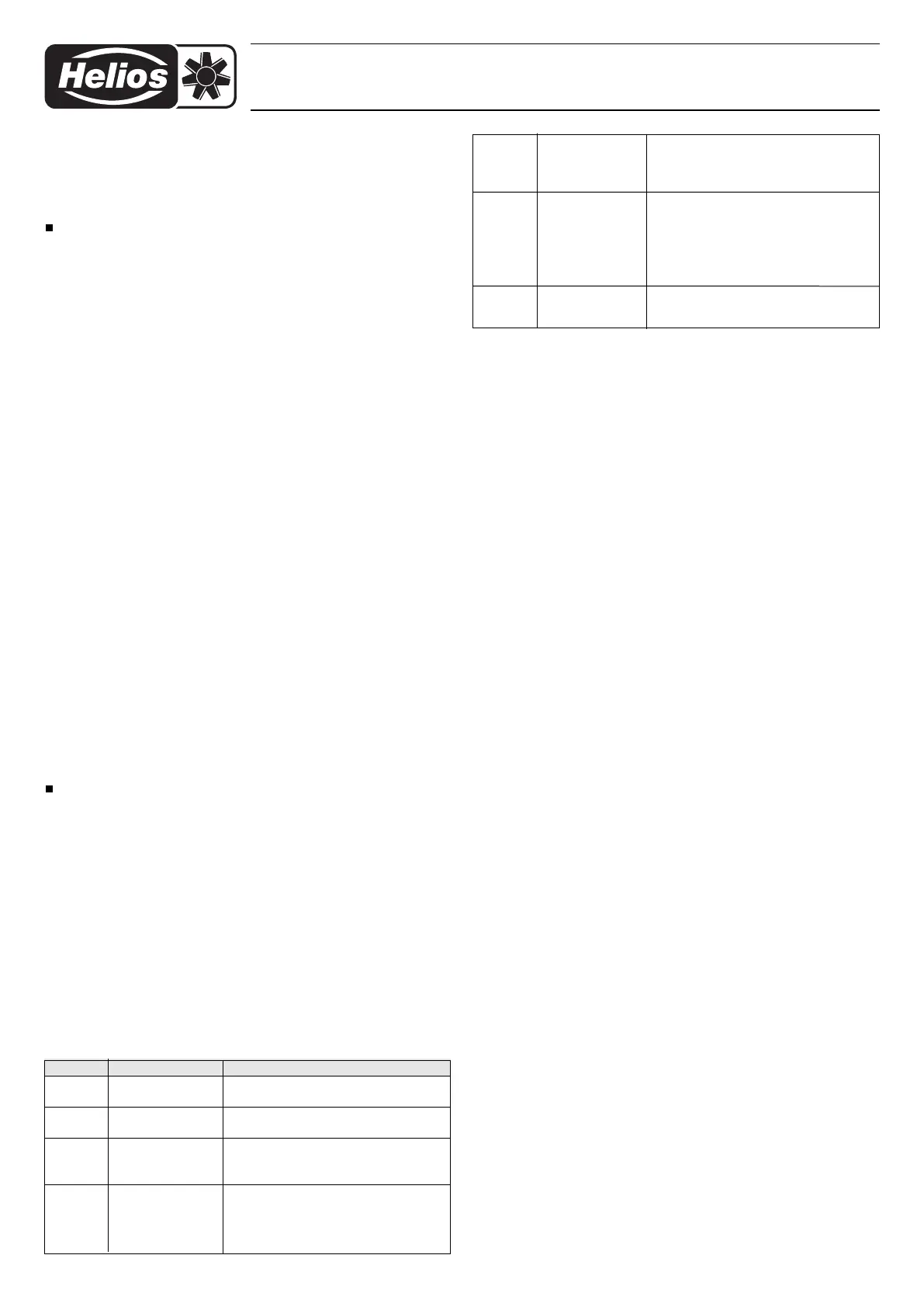

– DIP-Switch setting

Important: When putting the unit into operation the dip-switch settings and

the tempatures settings must be checked. It is recommended to carry out

customer specific setting on site if required.

Switch No. Recommend. setting Function

1 ON ON = After heater switched off in case of

Frost

OFF = After heater not switched off in case

of frost

2 OFF ON = After heater switched off on MIN

speed

OFF = After heater always on

3 OFF ON = Inlet air night set back of 3 °C

only with (if S2 is in OFF position)

KWL-WSU

OFF= No temp. night set back

4 ON ON = Air flow set to MIN during night

o

nly with KWL-WSU

OFF = no function

5 OFF ON = Pre heater is used as frost protection

a

nd additional (after) heating. Pre-

and after heater both work if set

inlet temp. is not reached (more KW)

O

FF= Pre heating is only used as frost

p

rotection

6 OFF ON = Frost sensor with Phono plug

OFF = Frost sensor with ISDN- plug

Notes and recommendation for settings: (see table above)

Switch No. 1

A

s the frost protection will reduce the speed of the intake air fan to speed MIN the

pre hater will provide the follwoing delta temperature:

K

WLC 350

V

.

=

100

m

3

/h r

esults in a

∆T o

f 30K

+

the heat of the heat exchanger. Therefore after heating is not required.

Switch No. 2

As the after heater is regulated by a temp. sensor it may also be used for speed

step „ MIN“ (position OFF), in order to achieve the desired inlet temperature.

Switch No. 3

W

hen using a KWL-WSU switch clock, if S2 is in OFF position, a temperature night

setback of 3°C can be acheived when setting S3 is in the ON position.

Switch No. 4

W

hen using a KWL-WSU switch clock, if S2 is in the OFF position, the air flow

may be set to MIN during the night if S4 is set to ON.

Switch No. 5

Under normal wheather condition the output of the after heater is sufficient. An

additional pre heating reduces the efficiency of the heat exchanger as the delta

temperature drops. The pre heater is only used for frost protection when S5 is set

to OFF.

Switch No. 6

(!) do not touch! see plug = ISDN - RJ 45 plug.

– Regulating the additional heating for units with electric heater battery

(Type KWLC 350...EH): (picture 5.)

The thermosat for the additional heating (1) is on top of the unit sensing the sup-

ply air after the heat exchanger. The thermostat is factory set at 15 °C, but can be

adjusted as required.

The heater is protected from overheating by a thermal overload thermostat (2). It

switches off automatically when the temperature of 65 °C has been reached. This

will reset automatically after having colled down. As an additional safety control, a

second thermostat switches off the whole unit if a temperature of 80 °C is excee-

ded (2.1). The thermostat can be manually reset by pressing the red push button,

which is accessible by removing the white plastic lid.

– Regulating the additional heating for units with water heater battery

(Type KWLC 350..WW): (picture 5, version WW)

The after heating is provided by a build-in water heater battery (7a). Intake and ex-

tract duct-work must be insulated to avoid ice build up on the water heater bat-

tery and the pipes. For regulation, a thermostat is positioned in the intake air duct,

which works as a closing contact. The volt free contact can be used to regulate a

valve.

Attention: The temperature sensor is located in the intake spigot. When intake

ductwork goes through cold areas, heat loss on the way to the valve must be con-

sidered.

– Frost protection of the Water Heater Battery (picture 5, version WW)

Intake and extract ductwork must be insulated to avoid ice build up on the water

heater battery. Directly in front of the water heater battery a frost protection ther-

mostat is positioned which closes at +5°C. The volt free contact of the thermostat

is to be connected with the heater control in a way, that the shunt valve opens as

soon as heater and circulating pump are switched off. This forced control avoids

the ice build up on the water heater battery. When switching off the heater be sure

that the water heater battery will be drained. Otherwise avoiding ice build up can-

not be guaranteed.

– Frost Protection of the Heat Exchanger Unit (picture. 5)

The sensor (3) for the frost protection thermostat is mounted where the extract air

leaves the heat exchanger. This sensor controls the intake air fan to avoid ice build

up. Warm air (e.g. from the bathroom) contains high humidity and therefore it is

Heat recovery unit KWLC 350

2

Loading...

Loading...