PAGE 9

© Copyright Hewland Engineering Limited

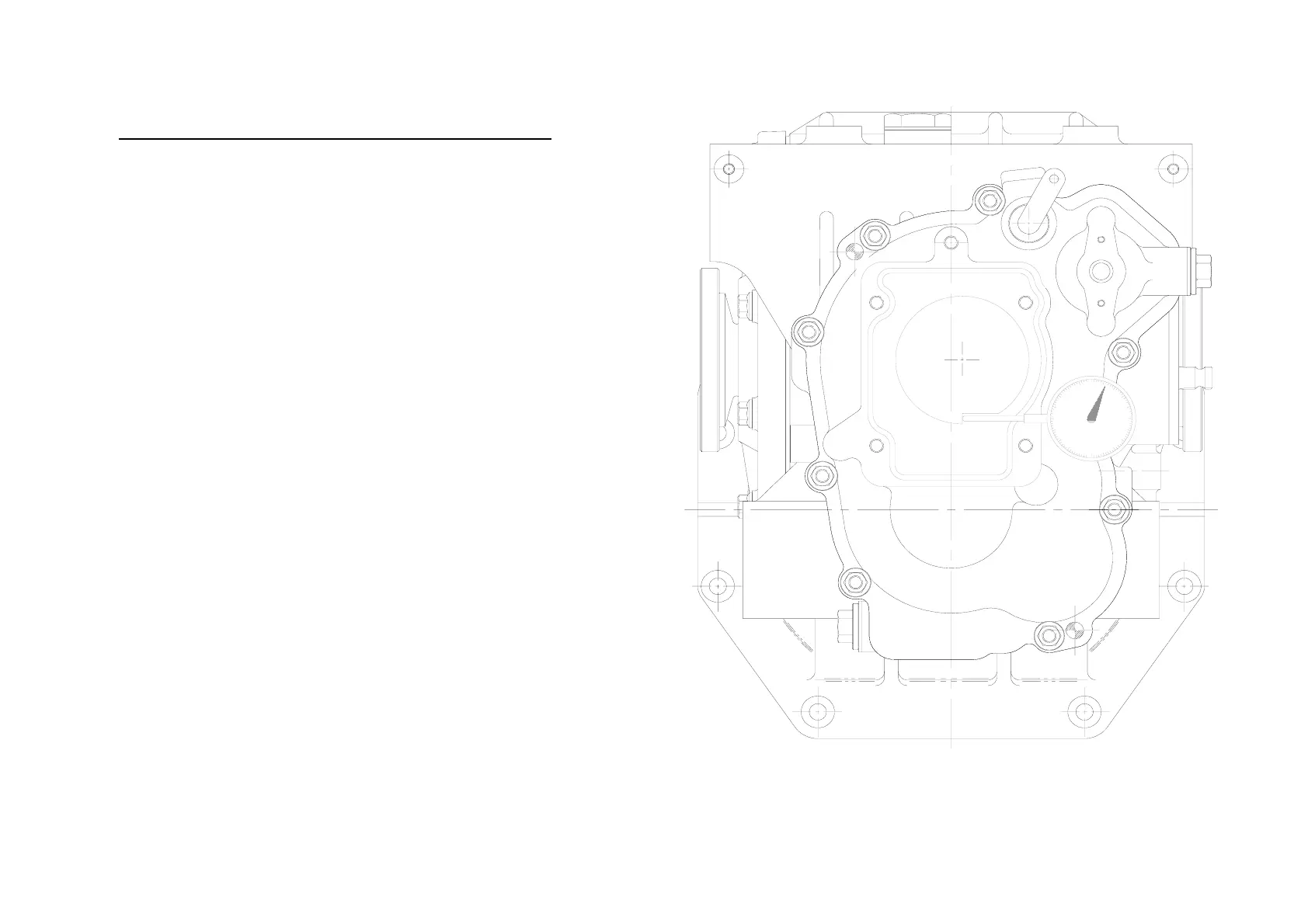

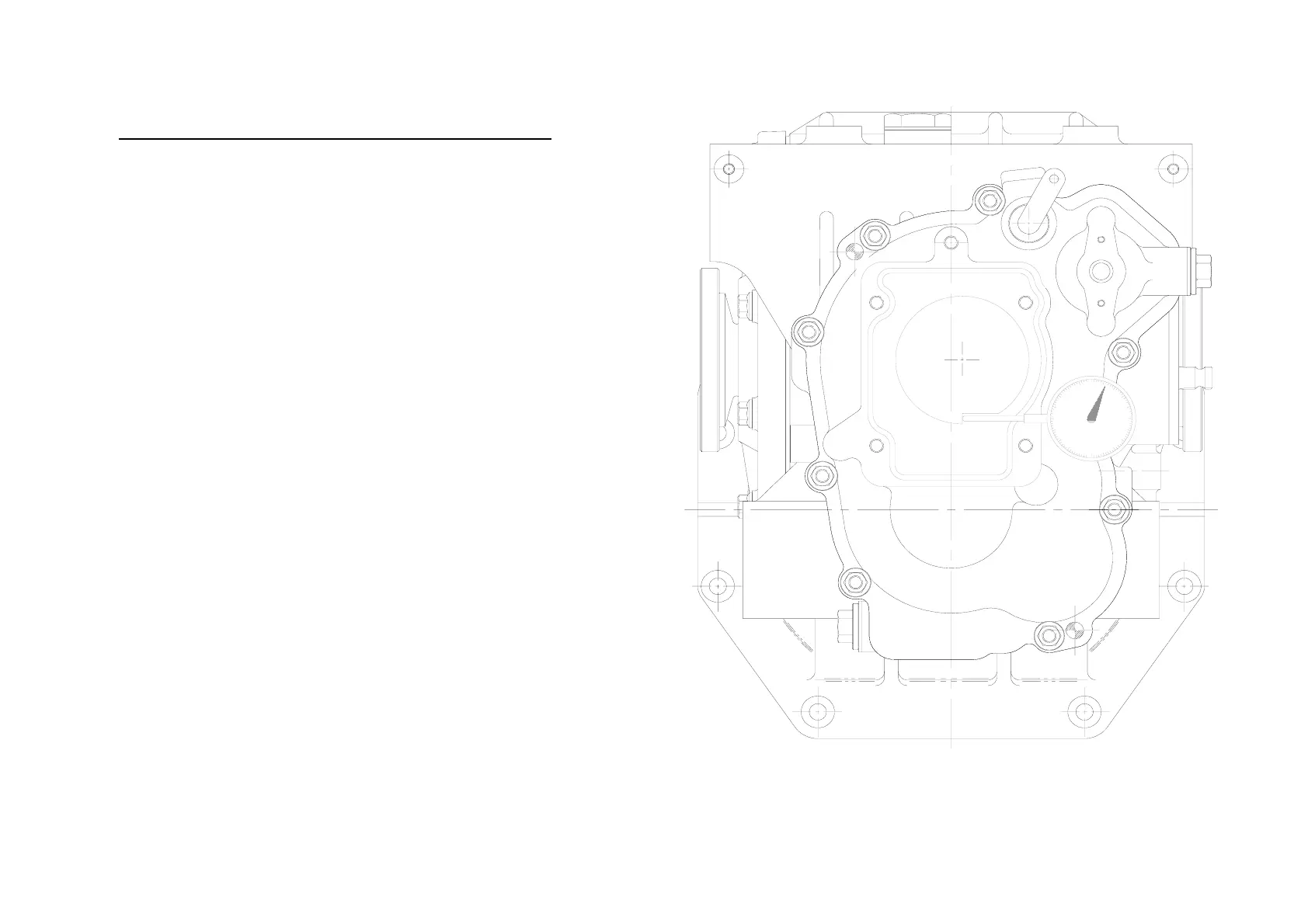

CROWNWHEEL & PINION BACKLASH SETTING

Requires special tool No. SK-1913

With the pinion shaft correctly fitted, and the correct diff

bearing shims ascertained, the actual backlash can be

measured by means of a dial test indicator against the

notch in the outside diameter of tool SK-1913. Be sure to

take at least 6 backlash readings, turning the crownwheel

30-45 degrees between each reading (this is to ensure

that any variation due to manufacturing tolerances are

taken account of.

The correct backlash figure should be taken from the

card supplied with the gears. If the measured backlash is

incorrect, rectify it by removing some shims (103) from

behind one diff bearing, and inserting them behind the

other, thus moving the diff across in the maincase. Do

not add or discard any shims at this stage, as to do so

would affect the diff bearing preload.

Once the correct backlash has been achieved, replace the

dummy bearings with bearings (83) and confirm that the

backlash is correct.

Note: Dummy are used so that it is easy to change the shims

during the setting procedures. Before fitting the actual diff

bearings, it is important compare thier width with that of the

dummy bearings and compensate the shims accordingly for any

difference.

FIGURE 4

Loading...

Loading...