)

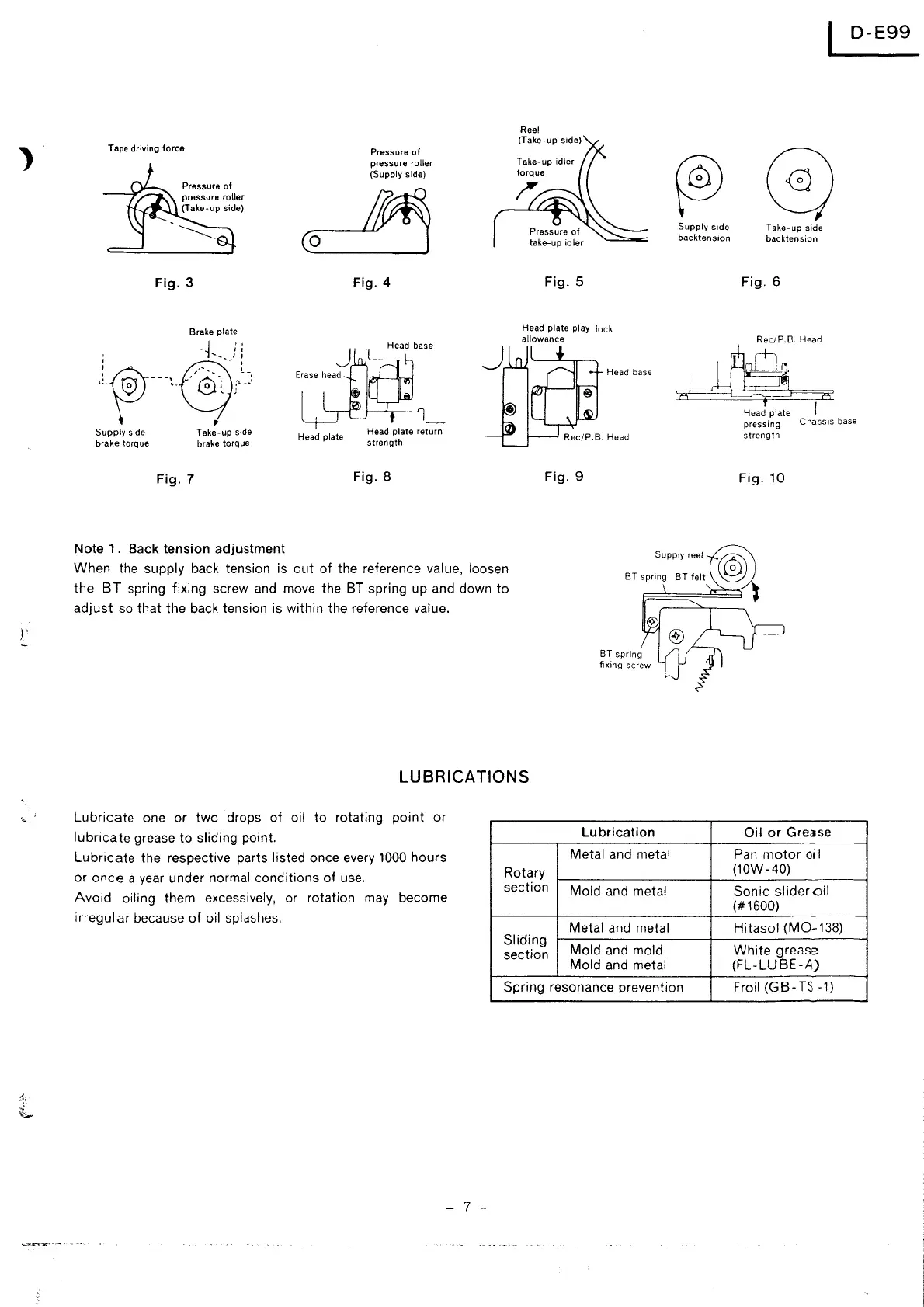

Tape driving

force

Fig.

3

Brake

plate

~

i : :

.i~-

'@>i'i;

Supply

side

Take-up

side

brake

torque brake

torque

Fig.

7

Note

1.

Back tension adjustment

Head plate

Pressure

of

pressure roller

(Supply

side)

Fig.

4

Head base

Head

plate

return

strength

Fig. 8

When the supply back tension is

out

of

the reference value, loosen

the

BT

spring fixing screw and move the BT spring up and down to

adjust

so

that the back tension is within the reference value.

Reel

(Take-

up

side)

Fig.

5

Head

plate

play lock

allowance

Fig.

9

BT

spring

fixing

screw

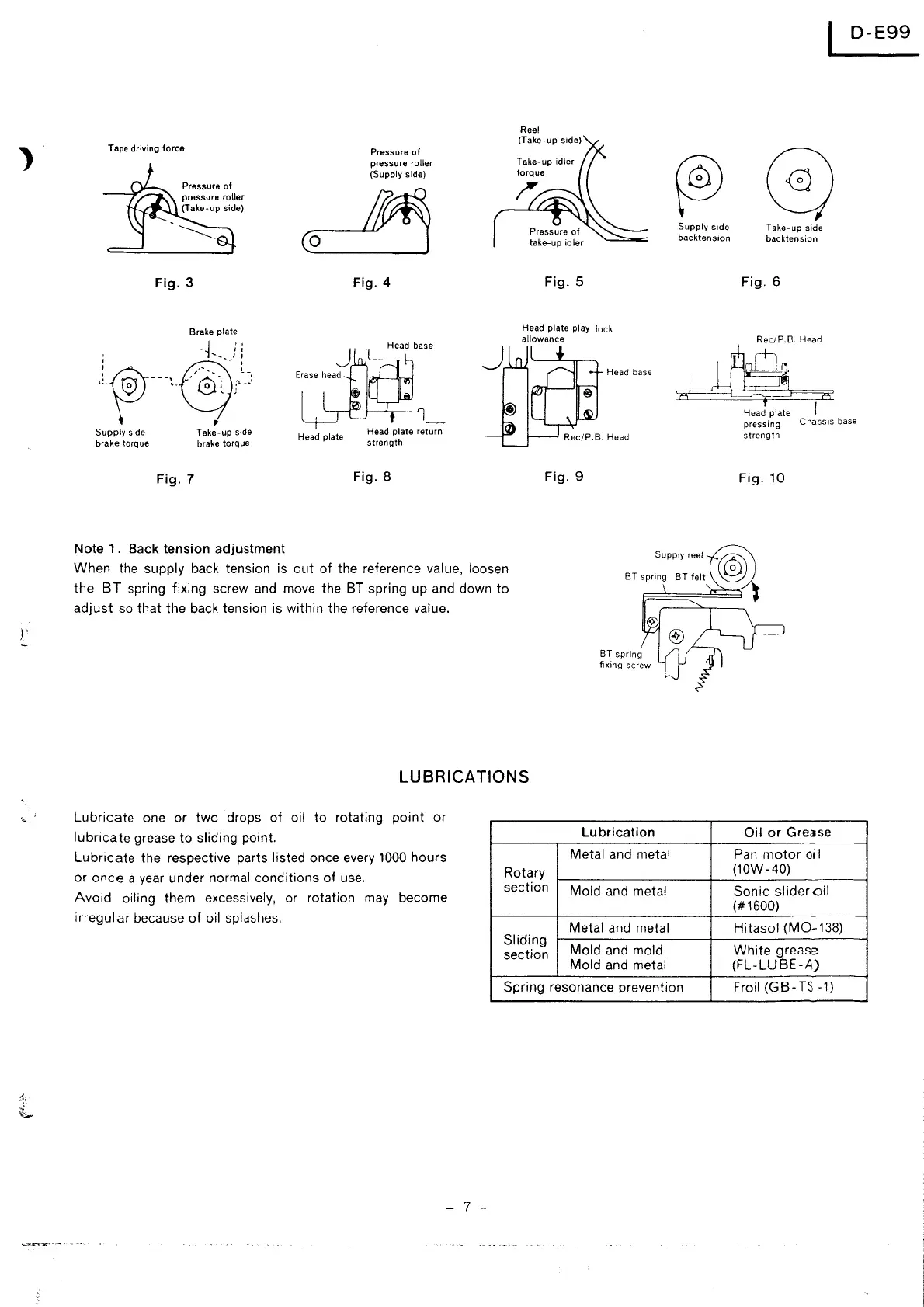

LUBRICATIONS

'· Lubricate one or

two

drops

of

oil to rotating

point

or

lubricate

grease

to

sliding point.

Lubrication

Lubricate the respective parts listed once every

1000

hours

or

once

a

year

under normal conditions

of

use.

Avoid

oiling them excessively, or rotation

may

become

irregular

because

of

oil splashes.

Rotary

section

Sliding

section

Metal and metal

Mold and metal

Metal and metal

Mold and mold

Mold and metal

Supply

side

backtension

Take-up side

backtension

Fig.

6

El~~

Head

plate

I

D-E99

pressing

Chassis

base

strength

Fig.

10

Oil

or

Grease

Pan

motor

oi

I

(10W-40)

Sonic

slider

oil

(#1600)

Hitasol

(M0-138)

White grease

(FL-LUBE-A)

Spring resonance prevention Froil

(GB-TS

-1)

- 7 -

Loading...

Loading...