44

5. INSTALLING AND PIPING [Piping the Air Compressor]

Water

Inlet

Water

outlet

Cooling drain discharge valve

① Leave the end of any condensate drain line open.

② Do not merge the air compressor’s condensate drain

lines (for the aftercooler, intercooler, control line

filter) into one common piping. Do not merge any

condensate drain line into an external condensate

drain line (for example, do not merge an air

compressor condensate drain line with a condensate

drain line on an air receiver tank). This could

generate a pressure differential, which could result

in no draining or inconsistent draining out of the air

compressor. Capability to observe the draining of

the air compressor is also impaired.

5.4.6 Drain Pipe

To drain

pit

Drain Pipe

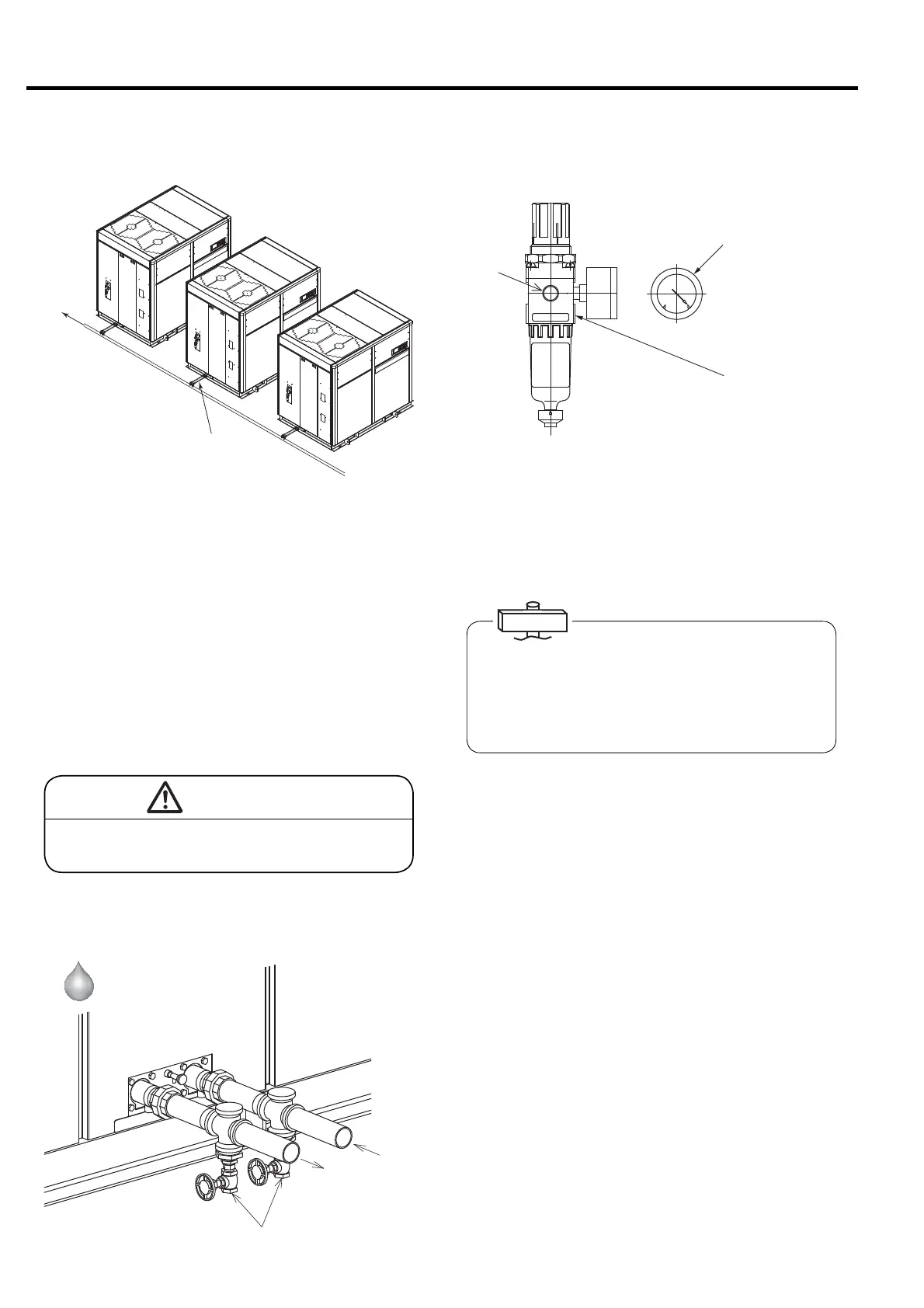

Pressure gauge

Filter regulator

The control air must be as dry as possible. Run the

control air pipe from the downstream side of the air dryer.

If an air dryer is not used, run the control air pipe from the

upper section of an air receiver. Installing downstream of

the air dryer or air receiver allows for less moisture

accumulation in the filter bowl of the oil mist remover.

5.4.8 OMR Control Air Piping

CAUTION

Un-drained condensate can backflow to the

air compressor and cause a failure.

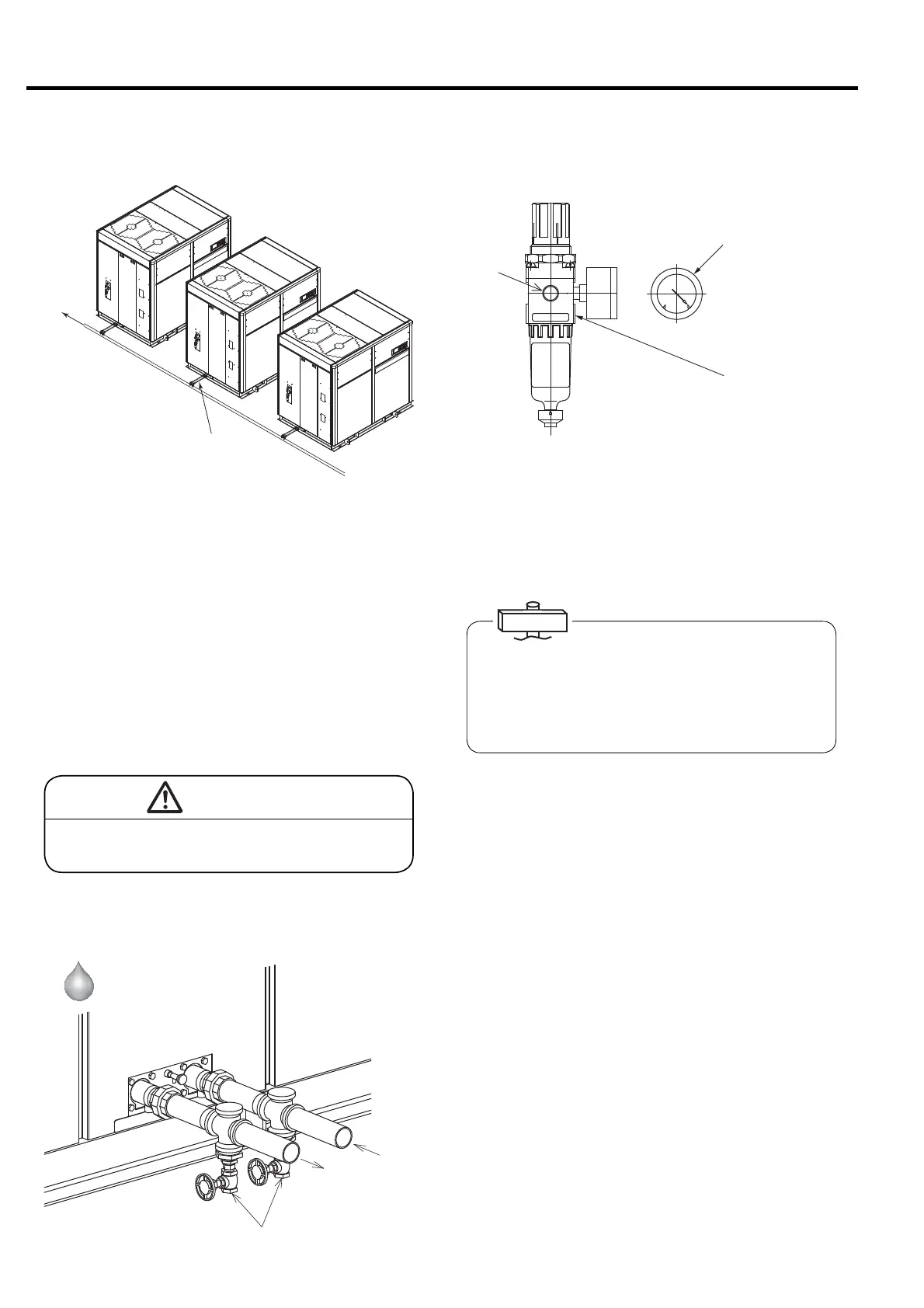

5.4.7 Cooling water piping

① The pipings for water inlet and outlet for coolers are

required.

② Mount the water drain valves of the cooling water

outlet and inlet downward facing downward as

shown in the figure. The water drain valves may

also be mounted facing sideways.

③ Using flange joint to connect the air compressor to

the water pipings, allows for minimal disassembly of

the enclosure panels.

IMPORTANT

The Oil Mist Remover needs the pressure of a control

air at the regulator setting value or more. To properly

install the control air line, connect the control air pipe

to the connection marked “A” on the filter/regulator of

the Oil Mist Remover. This piping and compressed air

shall be supplied by customer.

Water-Cooled

Loading...

Loading...