2 Mount the piping cover in order to avoid water entering into

the unit. Seal the holes where pipes and wires are inserted,

by using a insulation (eld-supplied).

3 If the eld-supplied piping is connected with stop valves

directly, it is recommended use a tube bender.

4 Check to ensure that the stop valves are closed completely

before connecting pipes.

5 Connect the eld supplied refrigerant pipes to the indoor unit

and outdoor unit. Apply the oil thinly at the seat are nut and

pipe before tightening.

6 After connecting the refrigerant piping, seal the open space

between knockout hole and refrigerant pipes by using

insulation material.

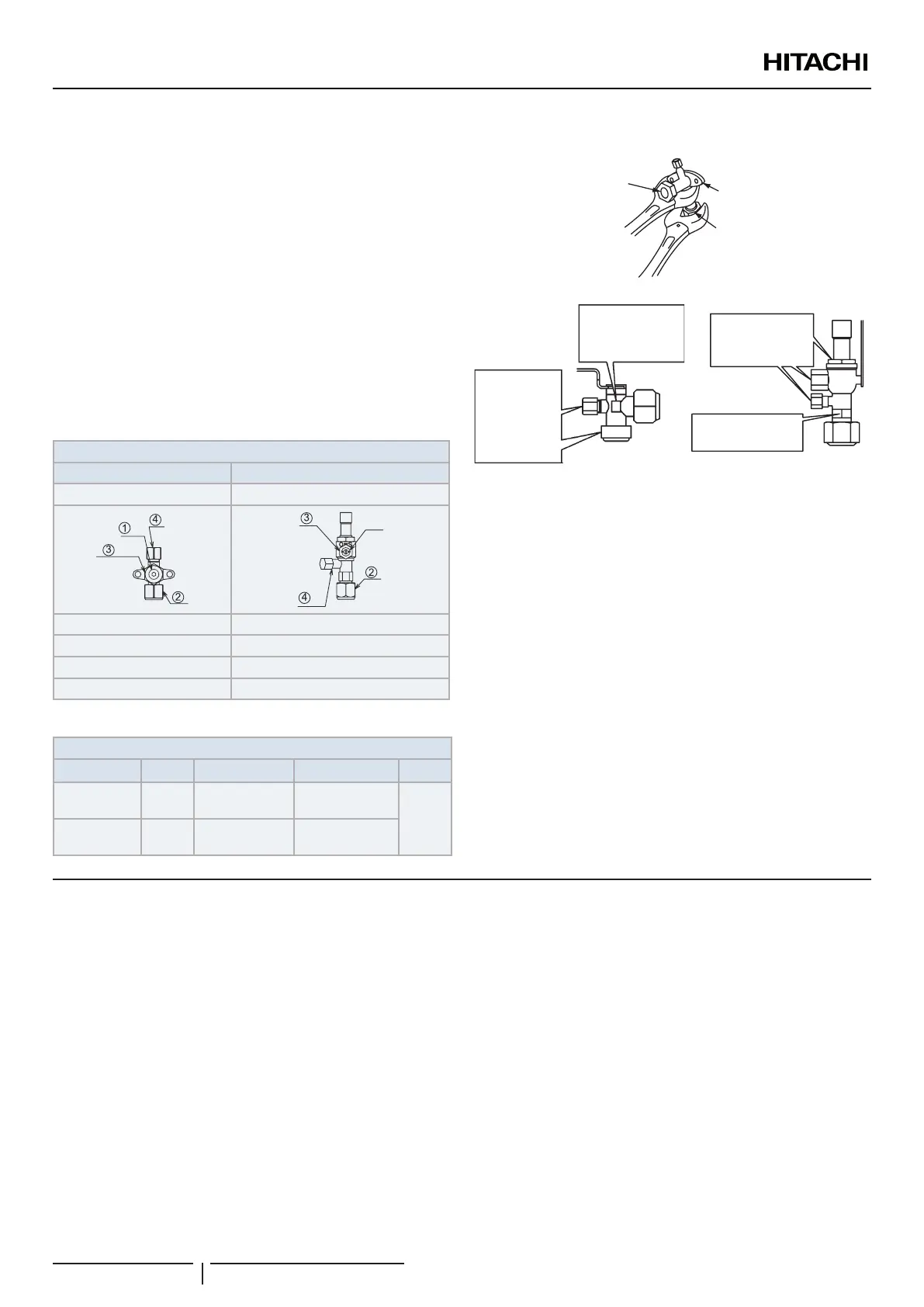

7 Operation of stop valve should be performed according to

the gure below.

Outdoor unit stop valve

Spindle Type Ball Type

Liquid Gas

(a)

Spindle valve

Flare nut

Cap

Check joint for service port

Closed upon factory shipping

Tightening Torque (Nm)

Liquid valve 7-9

40

10HP: 60

33-42

14-18

Gas valve 9-11

80

8/10HP: 100

(4-10)HP: 20-25

Do not apply

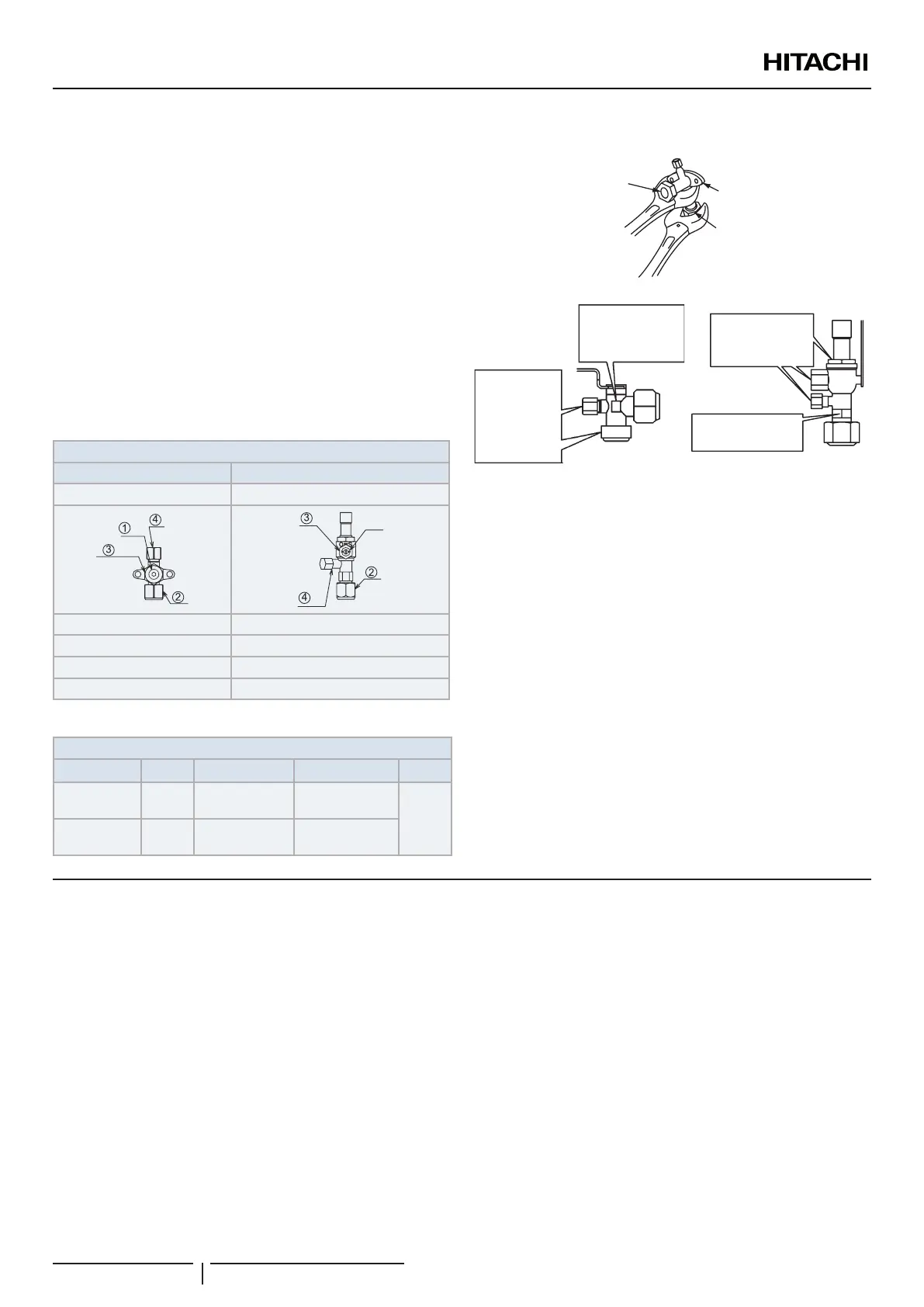

two spanners at

this position. If

applied, leakage

will occur.

Stop valve

(Spindle type)

Flare nut

Use two spanners

here for pipe

connection.

Do not work

with two

spanners here.

Refrigerant

leakage shall

occur.

Position to apply

spanners.

Do not apply two

spanners work

here.

Spindle type Ball type

! CAUTION

• Atthetestrun,fullyopenthespindleandballstopvalve.

• Ifnotfullyopened,thedeviceswillbedamaged.

• Donotattempttoturnservicevalverodbeyonditsstop.

• Donotloosenthestopring.Ifthestopringisloosened,itisdangerous

sincethespindlewillhopout.

• Anexcessorashortageofrefrigerantisthemaincauseoftrouble

totheunits.Chargethecorrectrefrigerantquantityaccordingtothe

descriptionoflabelattheinsideofservicecover.

• Checkforrefrigerantleakageindetail.Ifalargerefrigerantleakage

occurs,itwillcausedifcultywithbreathingorharmfulgaseswould

occurifarewasbeingusedintheroom.

8.3 BRAZING WORK

! CAUTION

• Usenitrogengasforblowingduringpipebrazing.Ifoxygen,acetyleneoruorocarbongasisused,itwillcauseanexplosionorpoisonousgas.

• Alotofoxidationlmwilloccurinsideoftubesifnonitrogengasblowingisperformedduringbrazingwork.Thislmwillbeeckedoffafter

operationandwillcirculateinthecycle,resultingincloggedexpansionvalves,etc.Thiswillcausebadinuencetothecompressor.

• Useareducervalvewhennitrogengasblowingisperformedduringbrazing.Thegaspressureshouldbemaintainedwithin0.03to0.05MPa.Ifa

excessivelyhighpressureisappliedtoapipe,itwillcauseanexplosion.

REFRIGERANT PIPING & REFRIGERANT CHARGE

PMML0372B rev.5 - 01/2021

10

Loading...

Loading...