. A complete Parts List is available at www.HobartWelders.com

OM-258 267 Page 14

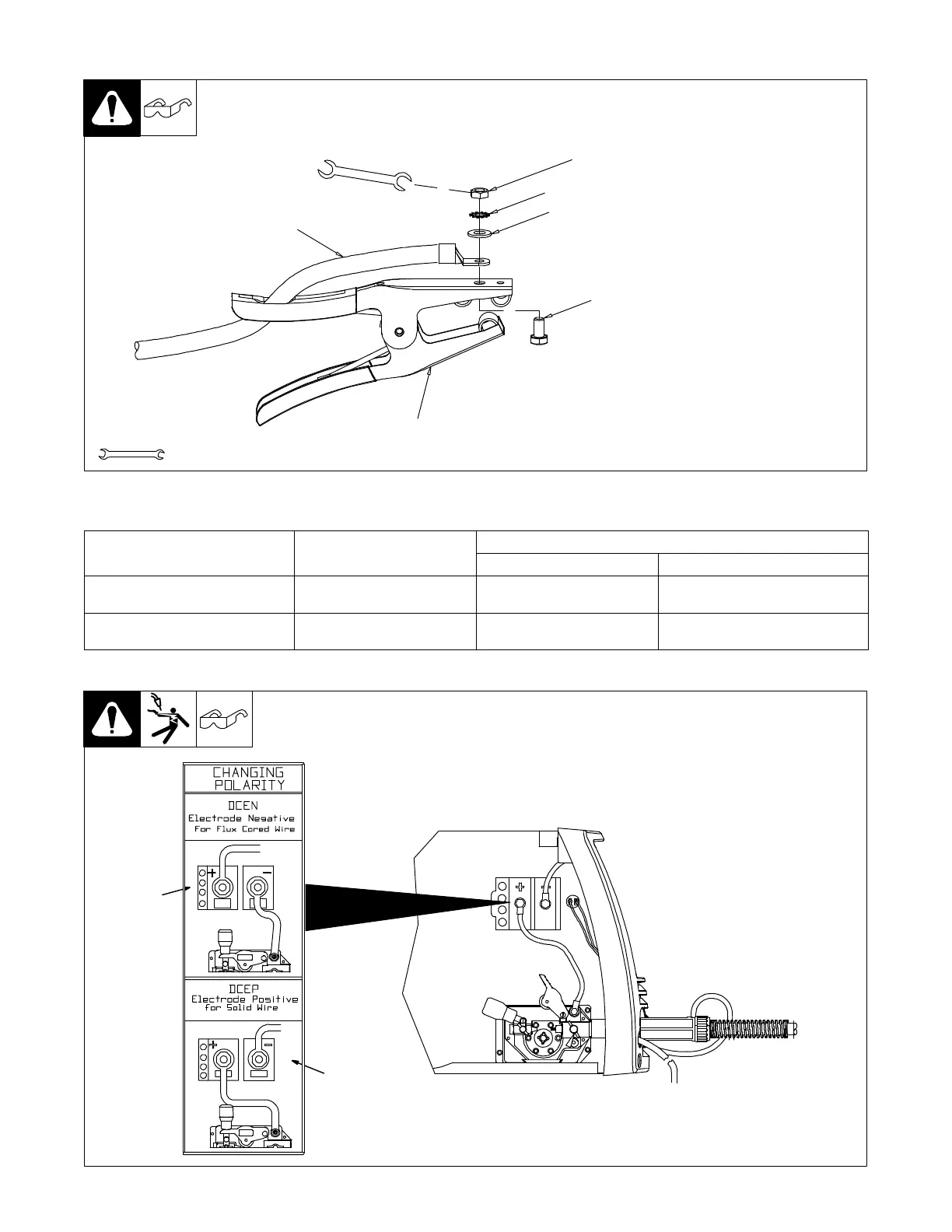

5-3. Installing Work Clamp

1 Work Clamp

2 Work Cable From Unit

3 Screw

4 Flat Washer

5 Lock Washer

6 Nut

Route work cable through hole in

clamp handle. Secure cable with

hardware as shown.

258 550-A

. Connection hardware must be tightened with proper tools. Do not just

hand tighten hardware. A loose electrical connection will cause poor weld

performance and excessive heating of the work clamp.

Tools Needed:

10 mm

1

2

3

4

5

6

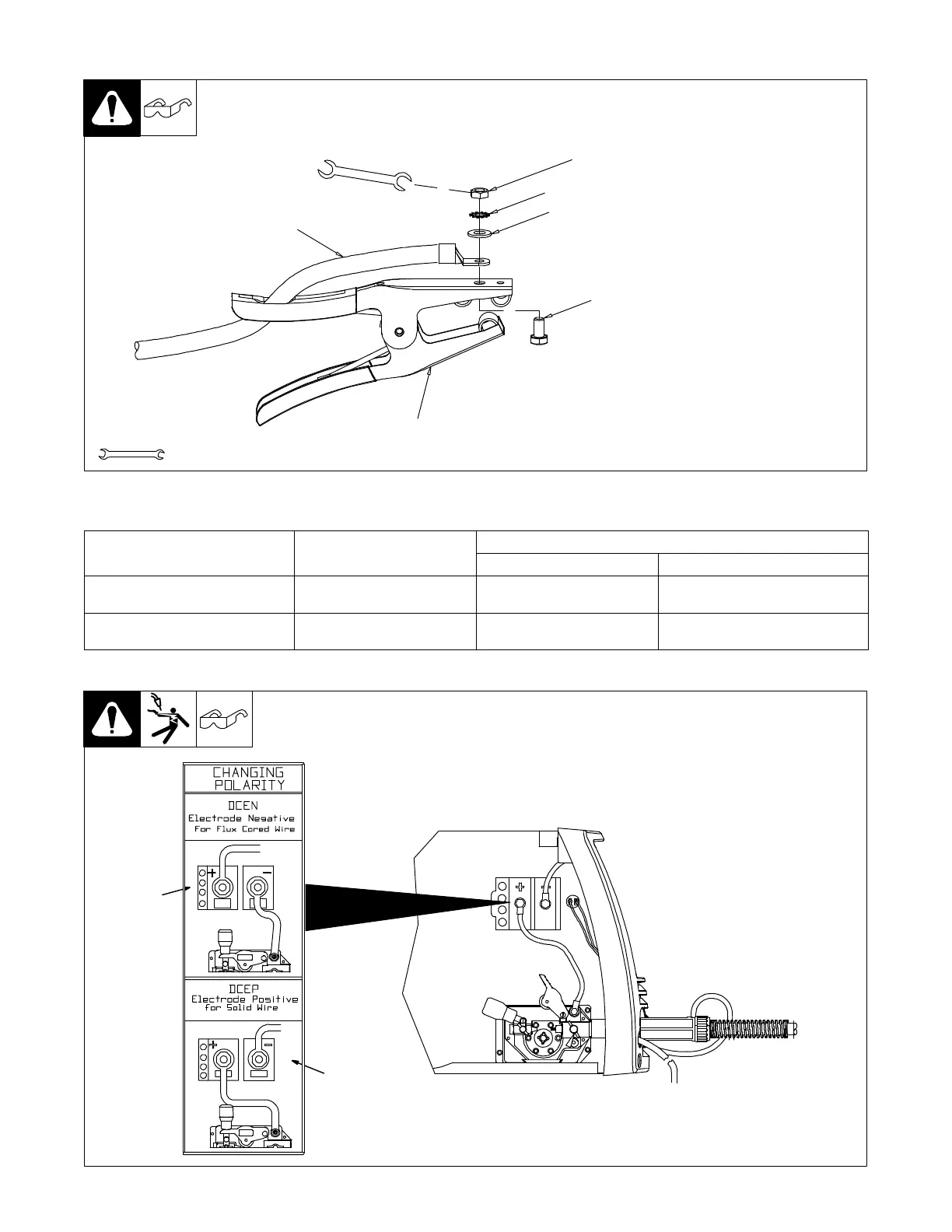

5-4. Process/Polarity Table

Process Polarity

Cable Connections

Cable To Gun Cable To Work

GMAW − Solid wire with shielding

gas

DCEP − Reverse polarity Connect to positive (+) output

terminal

Connect to negative (−) output ter-

minal

FCAW − Self-shielding wire − no

shielding gas

DCEN − Straight Polarity Connect to negative (−) output

terminal

Connect to positive (+) output termi-

nal

5-5. Changing Polarity

1 Lead Connections For Direct

Current Electrode Negative

(DCEN)

2 Lead Connections For Direct

Current Electrode Positive

(DCEP)

Always read and follow wire

manufacturer’s recommended

polarity, and see Section 5-4.

Close door.

258 321-A

1

2

Loading...

Loading...