2/03 10260A Series Actuators – Installation, Operations, and Maintenance 15

11.062 [280,97]

5.500

(139.7)

4.500

1.938

(49.21)

(114.3)

.563

(14.29)

1.625

(41.28)

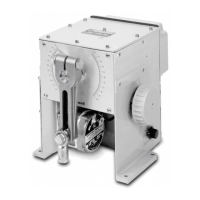

TAPPED HOLE FOR

1" CONDUIT.

ACCESS COVER TO

TERMINAL BOARD

2.500

(63.50)

ACCESS COVER

8.313

4.000

4.718

.813

(20.64)

5/16-24 UNF-2Bx.500 (12.7) DP.

TYP. 4 TAPPED HOLES EACH SIDE

.999 DIA. (25.38 )

KNURLED SHAFT

0.688

(17.46)

2.125

(53.98)

HANDWHEEL

MOTOR

(REF.)

(REF.)

7.688

3.844

(195.26)

(97.63)

6.000

(152.4)

DIA.

5.750

(146.05)

MOTOR

12.000

(304.80)

11.000

5.500

0.250

.438 (11.11) DIA.

TYP. 4 HOLES

.500

(12.7)

ACCESS COVER TO

SPUR GEARING

(211.15)

(121.43)

(101.6)

(6.35)

(139.7)

(279.40)

HANDWHEEL

8.750

(222.25)

3.105 [78,87]

SPACER

10.125 [257.18]

FULL CRANK

TRAVEL 90°

1/2-20UNF-2B X 1.239(31.47)

DEEP THREAD

MOTOR

2.125

[53.97]

MAX

5.000

[127.00]

MAX

2.155 [54.74]

0.596 [15.15]

1/2-13UNC-2B X 2 LONG

GRADE 5 OR BETTER BOLT

0.603 [15.32]

2.125 [53.98]

11.125 (282.58] MIN FOR COVER REMOVAL

CRANK ARM (GOLD) CONFIGURATION

TO MATCH CAST IRON (SILVER) CRANK ARM

ROD END CENTERLINE. USE KIT 51309755-501

NOTES:

1. ACTUATOR CAN BE MOUNTED IN ANY POSITION.

2. PROVIDE ADEQUATE CLEARANCE AT ALL ACCESS

COVERS FOR SERVICING AND ADJUSTMENTS.

3. WIRING DIAGRAM IS LOCATED ON THE INSIDE

OF THE TERMINAL BOARD ACCESS COVER.

Figure 3-2 Outline and dimensions of 10263A and 10265A Actuators

Loading...

Loading...