Troubleshooting

2/03 10260A Series Actuators – Installation, Operations, and Maintenance 73

9.2.4 Actuator does not control to the proper position.

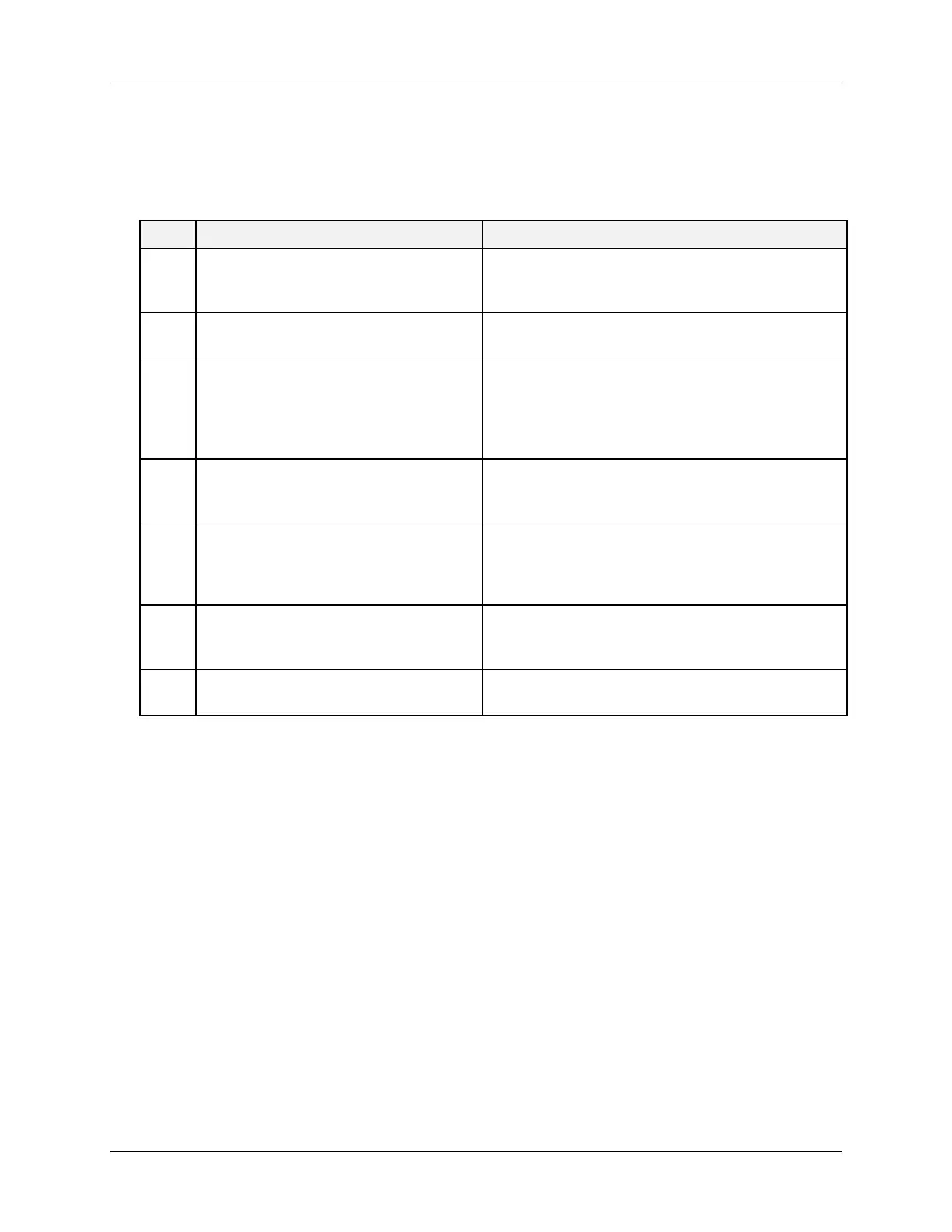

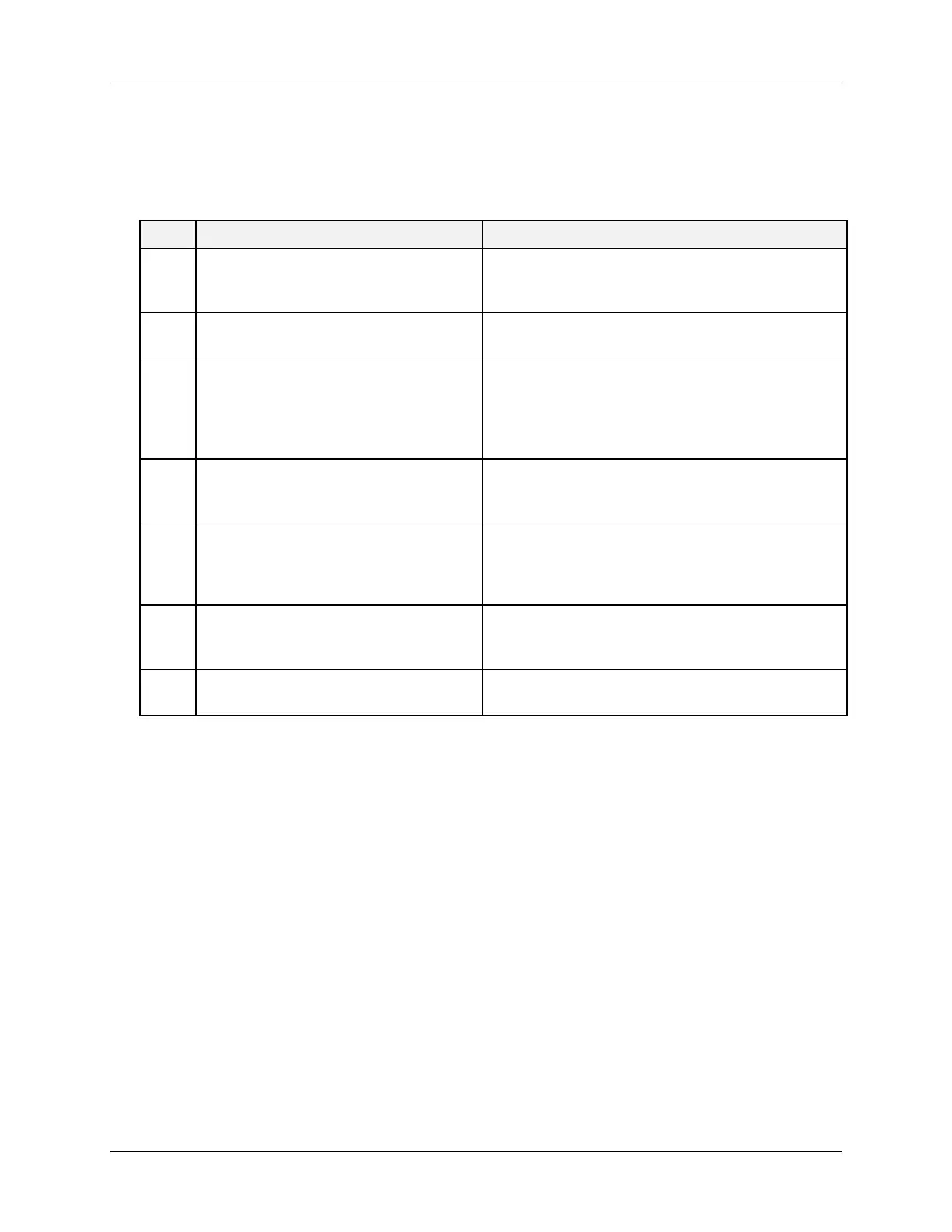

Table 9-5 explains how to troubleshoot the actuator for the correct control operation.

Table 9-5 Troubleshooting Control Action on Actuator

Step What to Do How To Do it or Where to Find the Instructions

1

Check the connectors to the Motor

Positioner Board.

Check to make sure connectors are securely

seated in headers on Motor Position board. See

Figure 4-5.

2

Check that cables are plugged into the

correct headers on NCS output board.

Check to make sure connector is seated in header

J4 on NCS board. See Figure 4-6.

3

Check NCS Output signal. On NCS Output Card, using a DVM, check that

the voltage across the pins of W11 (Figure 4-4) is

in the range of 0 to 1.25 Vdc. Check that voltage

is increasing for CCW operation and decreasing

for CW operation.

4

Check input signal. Using a DVM verify that the input signal at TB-30

to 31 (Figure 3-11) is in the range of 1 Vdc to 5

Vdc. If not check for the dropping resistor.

5

Check CW/CCW jumper Upon change of input signal, if actuator travels to

0 % or 100 % check to make sure CW/CCW

switch and jumper (Figure 4-6) are in correct

positions.

6

Check/Recalibrate Refer to Section 4 to recalibrate actuator. First

check Section 4.6 for proper positioning and

calibration of Non-contact Position Sensor.

7

Replace CAT/PAT Board. Refer to the replacement procedure in Section 8 –

Replacement/Recommended Spare Parts.

Loading...

Loading...