3.1 ALIGNMENT OF COMPRESSOR COUPLINGS (Continued)

If the gap is checked with the couplings “hard together”, ie, in the normal running condition, it should

be equal to the required coupling gap: 3.175mm (0.125”).

NOTE: If a “limited float” coupling is used with an electric motor whose shaft has no thrust bearing,

the gap must be correct with the motor shaft on its magnetic centre. In this instance the

facial alignment check should be made, rotating the driven half coupling only as the drive

(motor) half coupling is not located axially, or preferably by a “double-clock” method, which

avoids the problem of repeated axial position.

3.2 ALIGNMENT TOLERANCE

The maximum acceptable line-up tolerance for couplings on compressor installations is as follows:

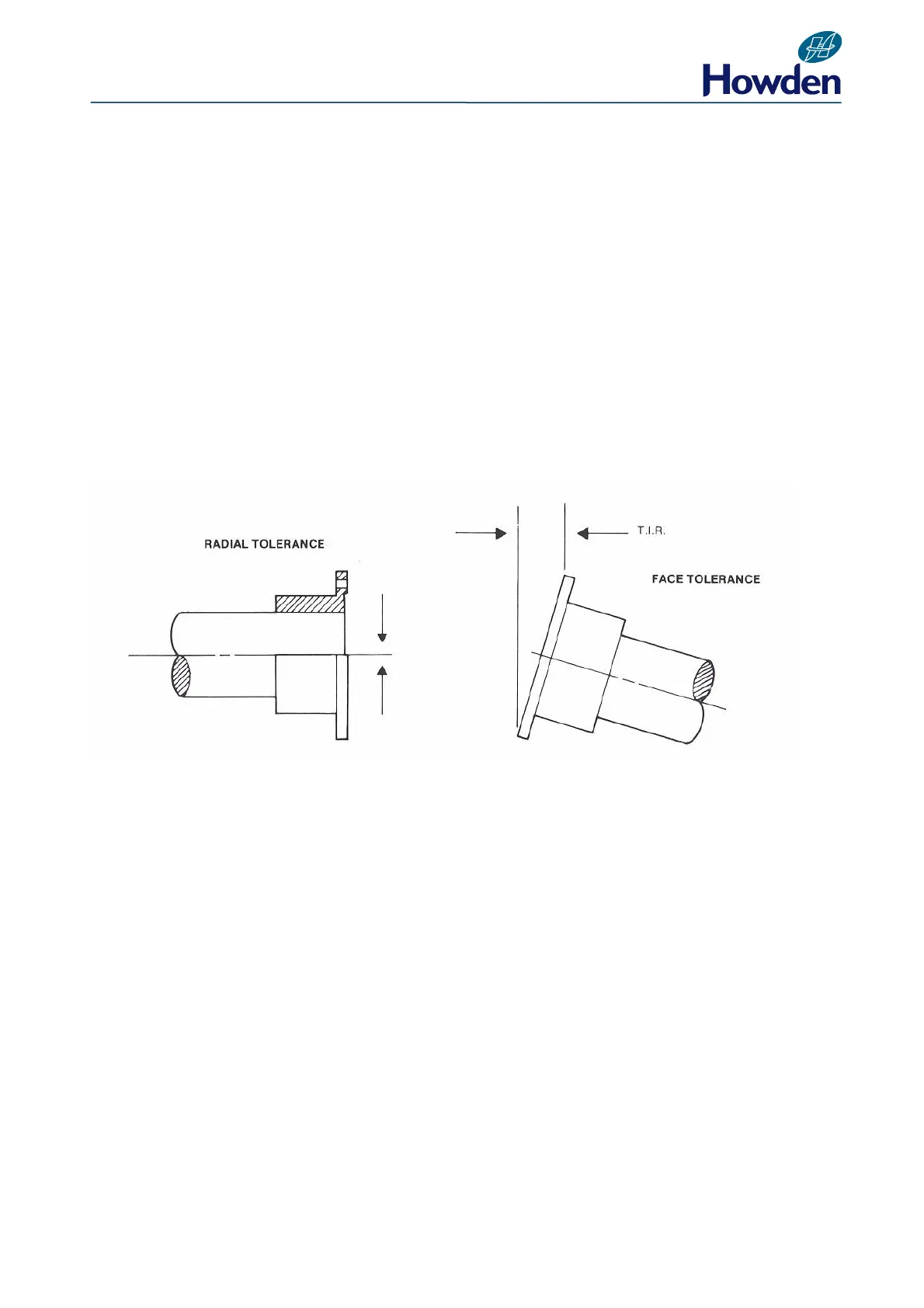

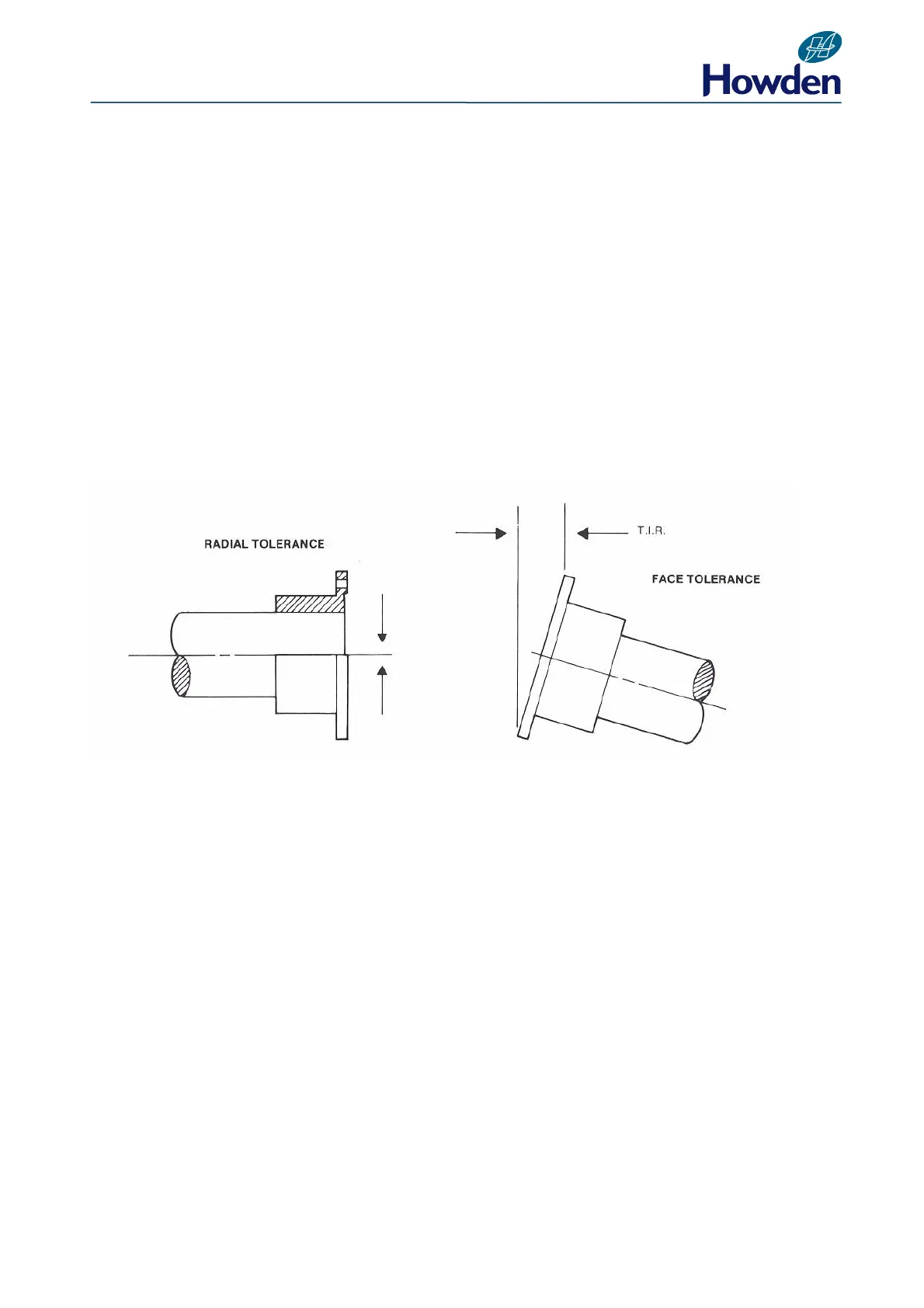

RADIAL TOLERANCE FACE TOLERANCE

Application

A. Motor to Gearbox or Compressor ie couplings operating up to 3,600 rpm

Radial Tolerance Face Tolerance

0.15mm (0.006”) TIR TIR 0.005mm/cm or 0.005”/in Dia. Of coupling

B. Gearbox to Compressor i.e. couplings operating above 3,600 rpm

Radial Tolerance Face Tolerance

0.10mm (0.004”) TIR TIR 0.005mm/cm or 0.005”/inch Dia. Of coupling

Radial Tolerance

Eccentricity = ½ TIR on circumference

TIR denotes Total Indicator Reading obtained by Clockgauge

Loading...

Loading...