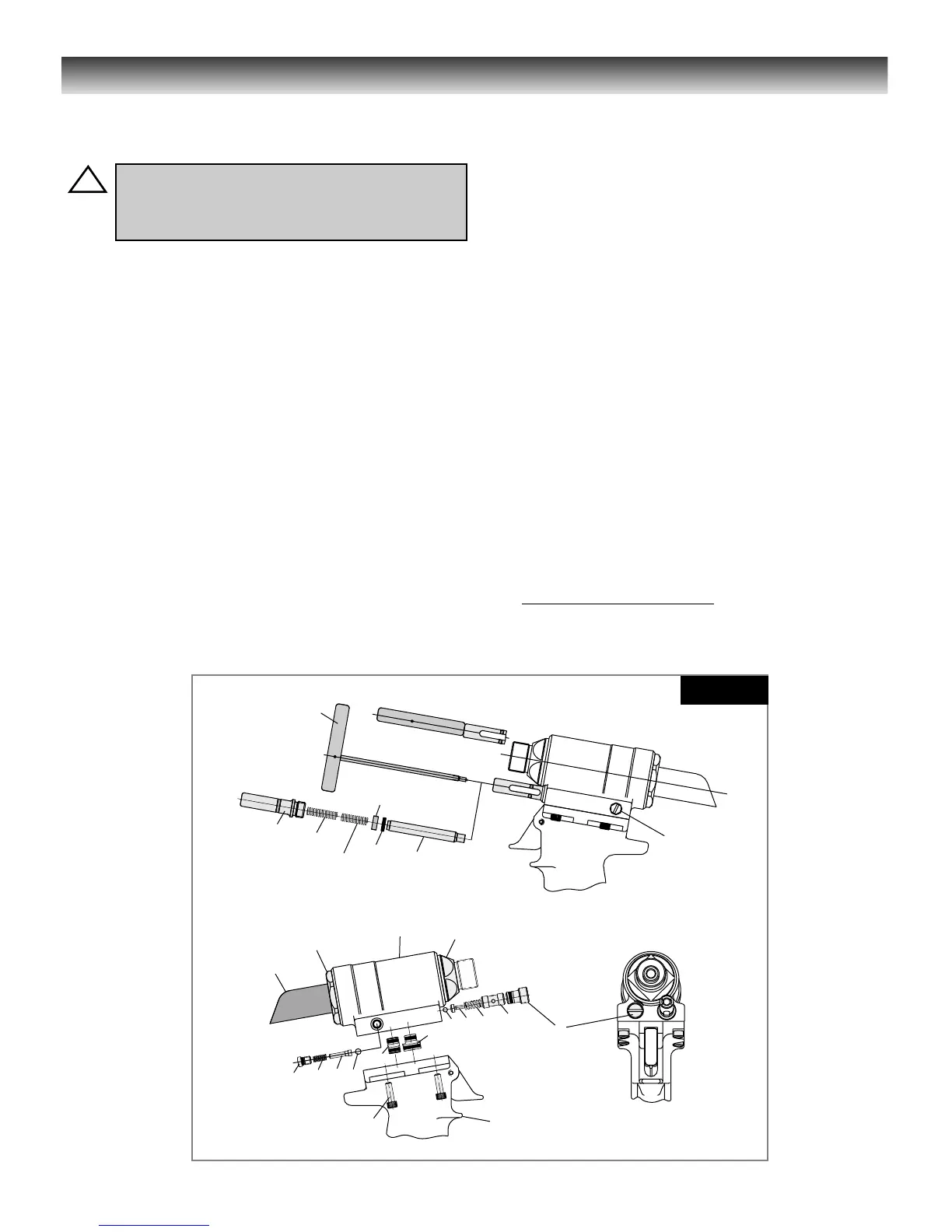

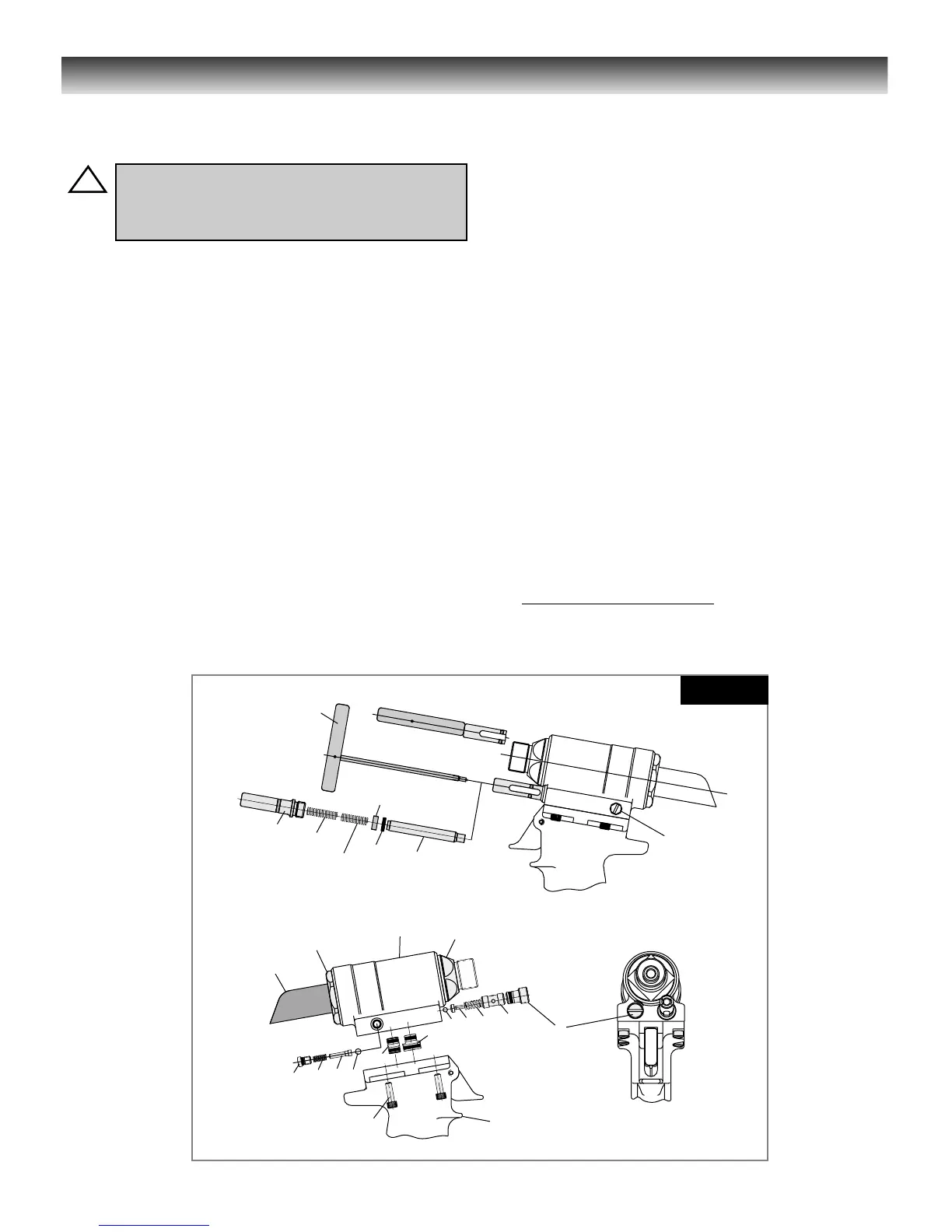

FIG. 1

Model 244/244OS Disassembly/Assembly

For component identification and Parts list refer to

Figures ( 9 & 10 ).

DISASSEMBLY

(Refer to Figures 1-3 and 9 & 10)

NOTE:

The following procedure is for complete disassembly of

tool. Disassemble only components necessary to

replace damaged O-rings, Quad-Rings, Back-up Rings,

and worn or damaged components. Always use soft jaw

vice to avoid damage to tool.

1. Disconnect air hose from tool.

2. Remove nose assembly. Follow instructions on Nose

Assembly Data sheet.

3. Insert Fill Tool, P/N 112465 through reservoir housing

and screw into Reservoir Plunger (73) locking it in the

out position (Fig1).

4. Unscrew Cap Screws (69) with 5/32 hex key. Carefully

lift Head straight up from Handle (1), remove Pull

Gland Assembly (29) and Return Gland Assembly (25)

from separated head and handle assemblies (Fig1).

5. Unscrew Plug (85) of return Pressure Relief Valve from

front of head. Remove Spring (84), valve Guide (82),

Sleeve (83) and Steel Ball (81). A small magnet is

helpful (Fig1).

6. Unscrew Bleed Plug (40). Hold over waste oil

container and release fill tool slowly (Fig1).

7. Unscrew Housing/Spacer Assembly (70) from head.

Remove two Springs (2x 71 for the 244 tool or 71 & 93

for the 244OS tool). Slide Reservoir Plunger (73) from

head. Remove spacer and Quad-Ring (72), a pick

may be used to remove the Quad-Ring (Fig1).

8. Unscrew Plug (78) of reservoir check valve from side

of head. Remove Spring (77), Check Valve Guide (76)

and Stainless Steel Ball (75) (Fig1).

9. 244 Model Only (Fig. 1 & 9)

Pintail Deflector (22) can be pulled off deflector tube at

rear of Piston.

WARNING: Be sure air hose is disconnected

from tool before cleaning, or performing

maintenance. Severe personal injury may

occur if air hose is not disconnected.

Loading...

Loading...